Thanks for the detailed response djozz!

-Garry

Thanks for the detailed response djozz!

-Garry

Cool! What did you use for the base and the “rings” for the light entrance and light meter? Looks like the base is thin cardboard? And the rings thin PVC?

My new lux meter should be coming tomorrow! (Curious to check it against my HS1010 to see if my HS1010 is off as badly as I suspect.)

-Garry

Looking immaculate! ![]()

I see that your entrance hole is quite long, so could you do a little experiment for me that I’m curious of?: could you check how (in percentage) the luxmeter reading differs while you move the flashlight up and down the hole. The reflecting mirror surface should make that the difference is not much (all light should be directed into the sphere, and the reflectivity should not differ too much either), I would like to know how much.

I think I must make one of these. It appears to hit a sweet spot between effort and accuracy.

BTW I’ve been using white paperboard stencils around the head of each light on my old light box. I assume the same could be used here to minimize light leakage, with no significant ill effects?

My old light box is also wrapped in aluminum foil to prevent contamination from outside light. Would that be pointless here, or might it still be relevant?

So djozz has made someone else here do something. Nice work djozz and zipelgas can I please put an order in?

Yep - all the assumptions are correct. Base is just a ring of cardboard and the rings are made out of plastic pill containers. I managed to find the exact right fit for the light meter, so I don’t have to fix it with tape:)

The difference was indeed not much, but I will get back to you with some exact numbers.

]

The intention of a good working light box is not keeping as much light in as possible (although you need to keep the light loss under a certain minimum to obtain enough integration) , but to keep the light loss as constant as possible (in other words: make the combined internal reflectivity of the sphere constant), which is a different thing. Then the multiplier is constant and the box is accurate. The flashlight that is held in the entrance hole provides the light for measuring, but also influences the combined reflectivity of the sphere. Wether you need white stencils around the light, or grey or even black, is not known, what you want is creating the same reflectivity as when the reference light was measured.

Outside light probably is usually so much less than your flashlight (unless moonlight is measured), that alu-foil is not really necessary, but it does no harm either, I think it would make me feel better too ![]()

50% off coupon good today at JoAnn Fabrics

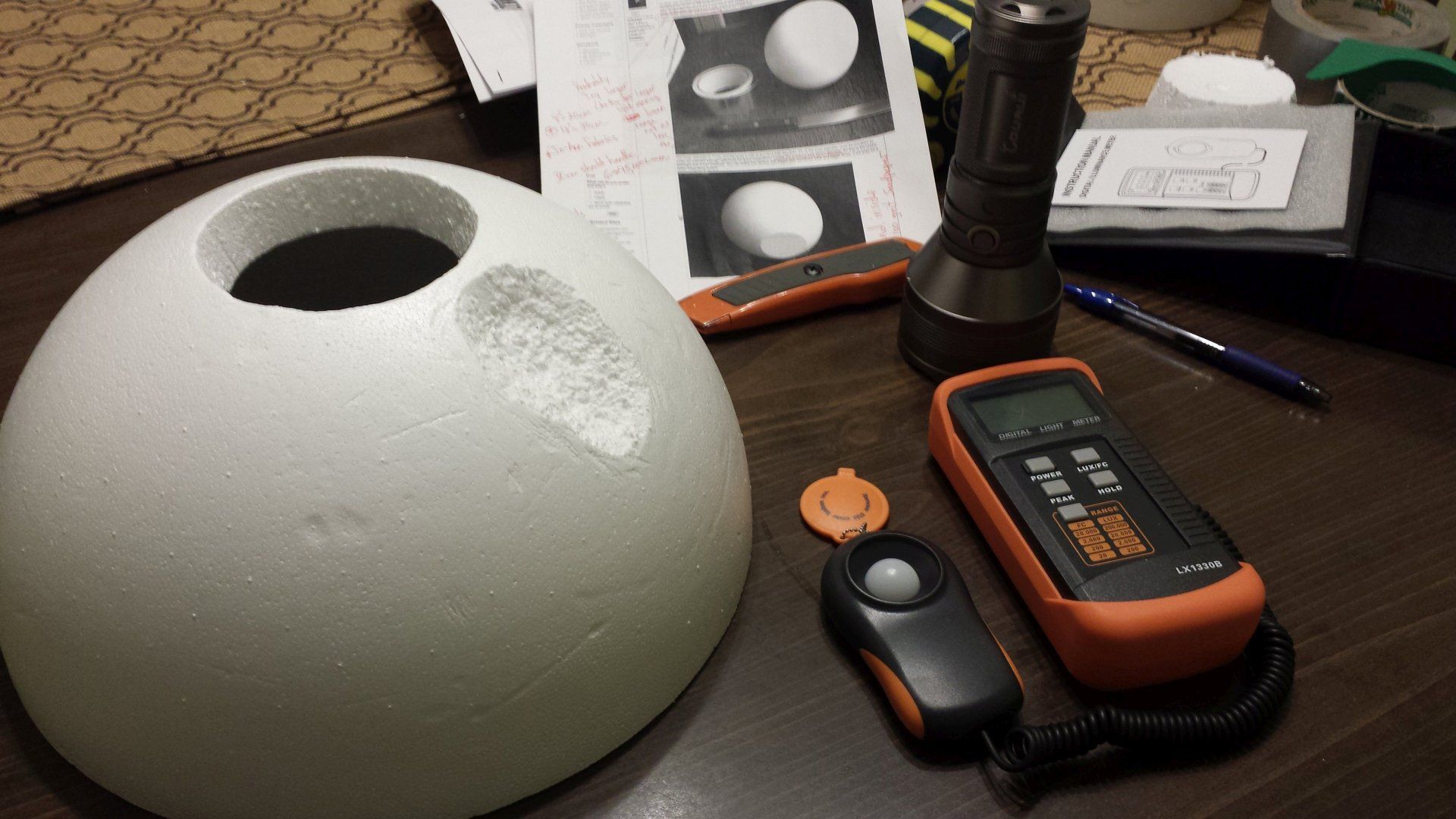

here is the ball

Going with Wifepoo today armed with 2 50% off coupons, $10 for a sphere is BLF kinda deal!

Later,

Keith

It just occurred to me:

-the measuring range of the 15cm sphere of the OP is 0-17,000 lumen (which is a useful range)

-with the same build, a 30cm sphere (with the same 2cm wall thickness) would have a range of 0-68,000 lumen, which is less useful because you will never measure this high output, and the resolution at the lowest light levels gets too low.

-to solve that, you could slice the wall of the sphere thinner at the position of the detector (actually like I sliced a bit off the sphere where I made the entrance hole), before attaching the ring, this will get more light to the detector and therefore bring the range down. So you can adjust the range by slicing more or less styrofoam off at the detector spot, and I can not think of a reason why this would affect integration in a grossly negative way.

First of all a little explanation why I left entrance port longer. I wanted to keep the inner surface vs ports ratio very small (about 3%) and still get a usable reading form some lights that are just a bit too large for the opening. So I tried to be a bit sneaky. I hope the pictures explain my plan a bit better…

The port is covered with aluminum tape, depth is about 32mm and the diameter is almost perfect for X6 and D80. So these will be the test lights.

X6 triple test2 – different output mode

So basically very little difference in lux reading when traveling almost 3cm up or down. When the head is pushed too far down inside the sphere, there is off course a sudden drop in numbers.

D80 test2

The last picture shows a drop, because the head is already too deep inside.

But as you can see, the numbers are not so stable anymore. Almost 10% difference. My best guess is that the culprit is reflective bezel?

Thanks a lot for the measurements ![]()

So the position in the entrance hole does make quite a difference, even with its reflective walls. Pity, that implies that you will have to define a fixed depth for your measurements (not that much of a problem though). Yes, it is the reflector that is increasing the overall reflectivity of the sphere, and when it is too deep in, the side of the head is eating light, and with so many reflections going on, it is soon adding up to a considerable loss of reflectivity. With a bigger sphere the things going on in the entrance hole will have less influence on the reflectivity (multiplier).

If you like this DIY tinkering, you could build a reflectivity measuring light into your sphere, to compensate for entrance hole effects, but it will definitively not be a fast build anymore. See for an example my integrating sphere #3.

sub

The first two tests done with X6 triple had very stable results. Surprisingly stable!? But this was a triple with tir optics = no reflecting surfaces whatsoever.

From 444 -> 455 and from 217 -> 222. That is only 2,5% increase if you consider that the travel distance inside the entrance was over one inch.

With lights giving more unstable results (like the D80 in this example) it’s very intuitive to find the sweet spot. You start lowering the light inside (lux numbers climbing) and the moment the numbers start to decrease you pull the light back just a little bit.

I found that this basically means that the flashlight is almost flush with the inner surface or just a bit higher.

But these were just a few quick tests. I have not had a lot of time to play with my ball ![]()

So the “correct” lux reading will be the “max” number while sliding the light in and back out?

Like tigris99 posted at MTBR (not sure if he posted it over here). Pic:

Here ya go, funny how we call big lights Chunky Monkeys. This is fitting (in more ways than one)

Just tried this on a whim and Waalaa!

This can fits the Courui D01 light perfect and the inside rim should be helpful for using adapter rings for small lights.

Will get the can cut and set up the sphere later this week.

Enjoy!

Keith

My integrating sphere (or as my 3yr old says, “integrating spear”) is nearly complete. I started using duct tape instead of aluminum tape but then realized the duct tape lets an awful lot of light through it, so I used black electrical tape over the duct tape. Some pics:

The hole ended up at 90mm and tapered in (hope that doesn’t hurt me):

Created an indent for my luxmeter sensor which made it start to look like the Death Star ![]() :

:

Dug out some more “foam” to get the sensor to sit in place a little deeper and make it easier to get in the same location each time:

Luxmeter sensor in place (will likely add velcro strap):

The way it will look once finished, after mounting two sections together and attaching to the base:

-Garry

I will post there tonight, have to prepare dinner first! (chili)

I’m kind of pondering adding a reference light to this design… I have a ZL SC52 with very consistent output, and could either make a separate hole sized just right for it… or perhaps give it an incomplete slot with the last bit of the hole still filled in by foam. Not sure what the best approach is.

Which of these do you think would work best?

I also have a few reference lights to choose from… will figure out later which might work best:

The tail clicky on the last three might be a big advantage.