Ouch… I’ve used the nut guide method in the past on a pontiac engine build tapping to replace push-in rocker arm studs with screw-in studs intended for a big block chevy (after adding helicoils). After damage from a saboteur (one of my brothers) a big block chevy rocker arm broke but the studs held. 700+ hp engine. 1958-1963 big block pontiac engine converted to hei and coupled to a 400 turbo trans in a 77 firebird formula. It produced enough torque you could feel the car twist.

Yes, some light oil.

I am sorry, such things are always annoying. But that’s the right attitude, if you have to do it again then at least it’ll be an improved version

Out of action for a bit. See op.

Sorry to hear that. Get well soon, take care of it and do what the docs/therapists say

Thats no good at all RBD. It looks like you have a bit of carnage to your thumb as well with the big groove in it. Get well soon. ![]()

Very nice project you have going. I hope you heal up quick.

Ouch! Best wishes for fast healing!

Thumbs fine, that’s just the elastic bandage wadding me up. After the first 24 hours the wrist is pretty stiff and ~50% oversized. Feels like a stubbed toe right in the joint. Another day and it will be more colorful, already showing a bit yellow.

Any sympathy from the better half?

As usual, no. She thinks I’m an idiot. This time she’s spot on.

Argh - sorry to hear about the setback.

Sorry about your mis-hap RBD! Hope you get rollin’ again soon!

That’s what my wife would think. Is it possible that we are both married to the same woman?

Sorry to hear about the mishap. They say a bad sprain can sometimes hurt more than a broken bone. Hope you heal fast.

Me too. I passed out walking to stick it in ice water. Came to ~20’ from my last conscious position. Took about half an hour to pull myself together. First 24 hours was ice packs an now I’m alternating with compression bandage and heat. Wilma has me locked out and I can’t reach my beer though. :cry:

While this is healing I’ll continue to do what little I can which doesn’t seem to be much since I need my hand more than my elbow. I was able to use that elbow to finish the siding job where I got the injury. A smallish job ~ 250 square FT of hardi plank.

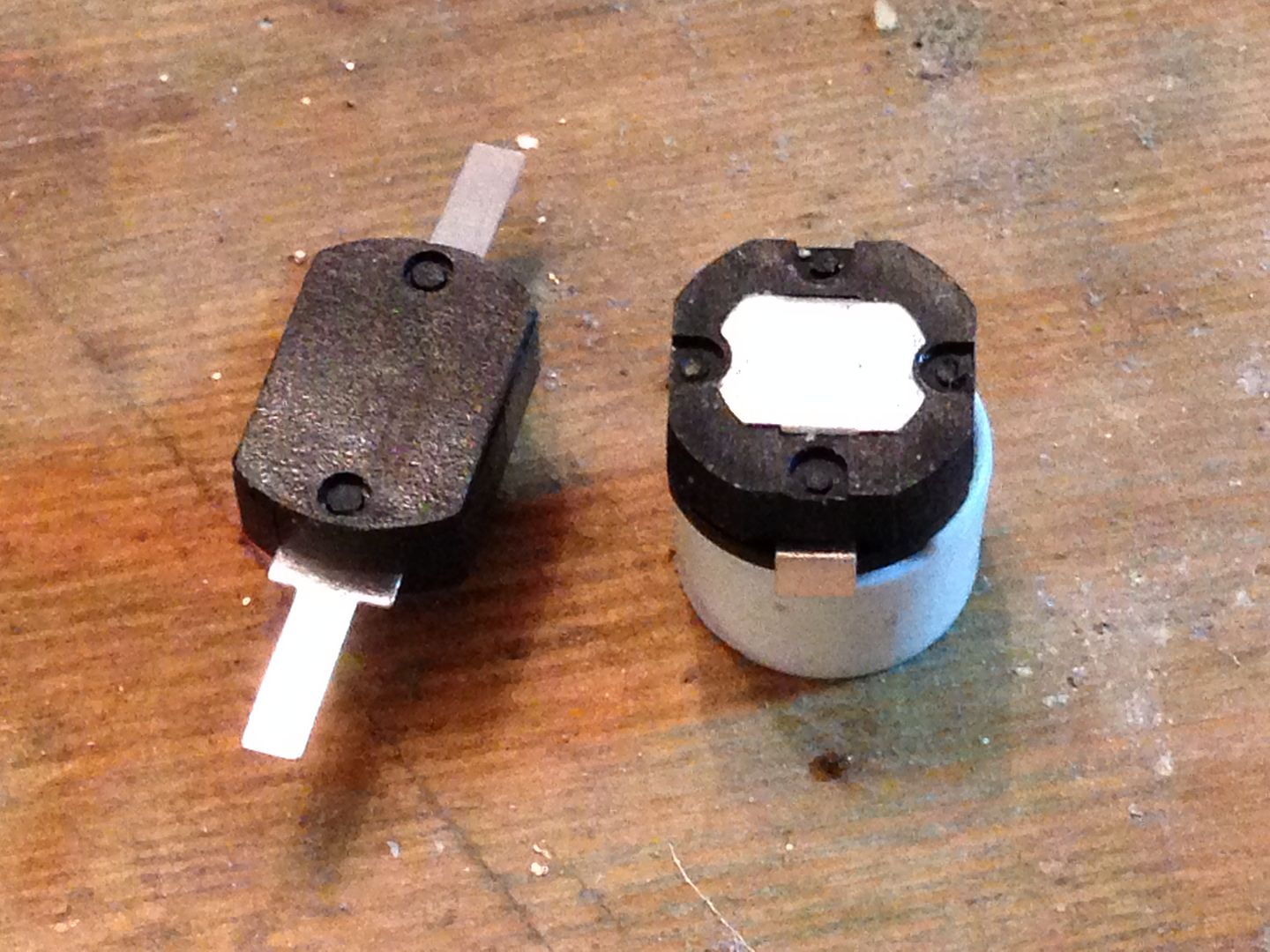

I had to finish the areas above the windows and garage door with the bum hand. Climbing ladders with a plank and a nail gun. I’m just glad it’s done. After that you’d think a half gram switch mod would be easy. These are my options; a mini omten and a 10mm round switch.

I had to finish the areas above the windows and garage door with the bum hand. Climbing ladders with a plank and a nail gun. I’m just glad it’s done. After that you’d think a half gram switch mod would be easy. These are my options; a mini omten and a 10mm round switch.  These switches are commonly held together by pins that are fortunately visible on these.

These switches are commonly held together by pins that are fortunately visible on these.  First I’ll open one up.

First I’ll open one up.

Aside from the shape, the functional difference between the two is that the omten uses the contact “rivet” to bridge the tabs at either end while the round switch uses the rivet spring to bridge from the tabs to the spring base plate which limits current to ~1/2A before the spring overheats. The mod is simple consisting of just cutting the contact plate in two and no longer using the spring base as a contact point.

Aside from the shape, the functional difference between the two is that the omten uses the contact “rivet” to bridge the tabs at either end while the round switch uses the rivet spring to bridge from the tabs to the spring base plate which limits current to ~1/2A before the spring overheats. The mod is simple consisting of just cutting the contact plate in two and no longer using the spring base as a contact point.  I guess the shears were a bit large for the job. I used a Dremel to open up the gap a bit more then sanded the edges and put it back together. I’ll remove the pieces again when I solder wires to them.

I guess the shears were a bit large for the job. I used a Dremel to open up the gap a bit more then sanded the edges and put it back together. I’ll remove the pieces again when I solder wires to them.  This made the hand ache considerably as the elbow was no help at all.

This made the hand ache considerably as the elbow was no help at all.

Another small update

This is more unseen miniaturization work. Looks good RBD, the recovery that is. ![]()

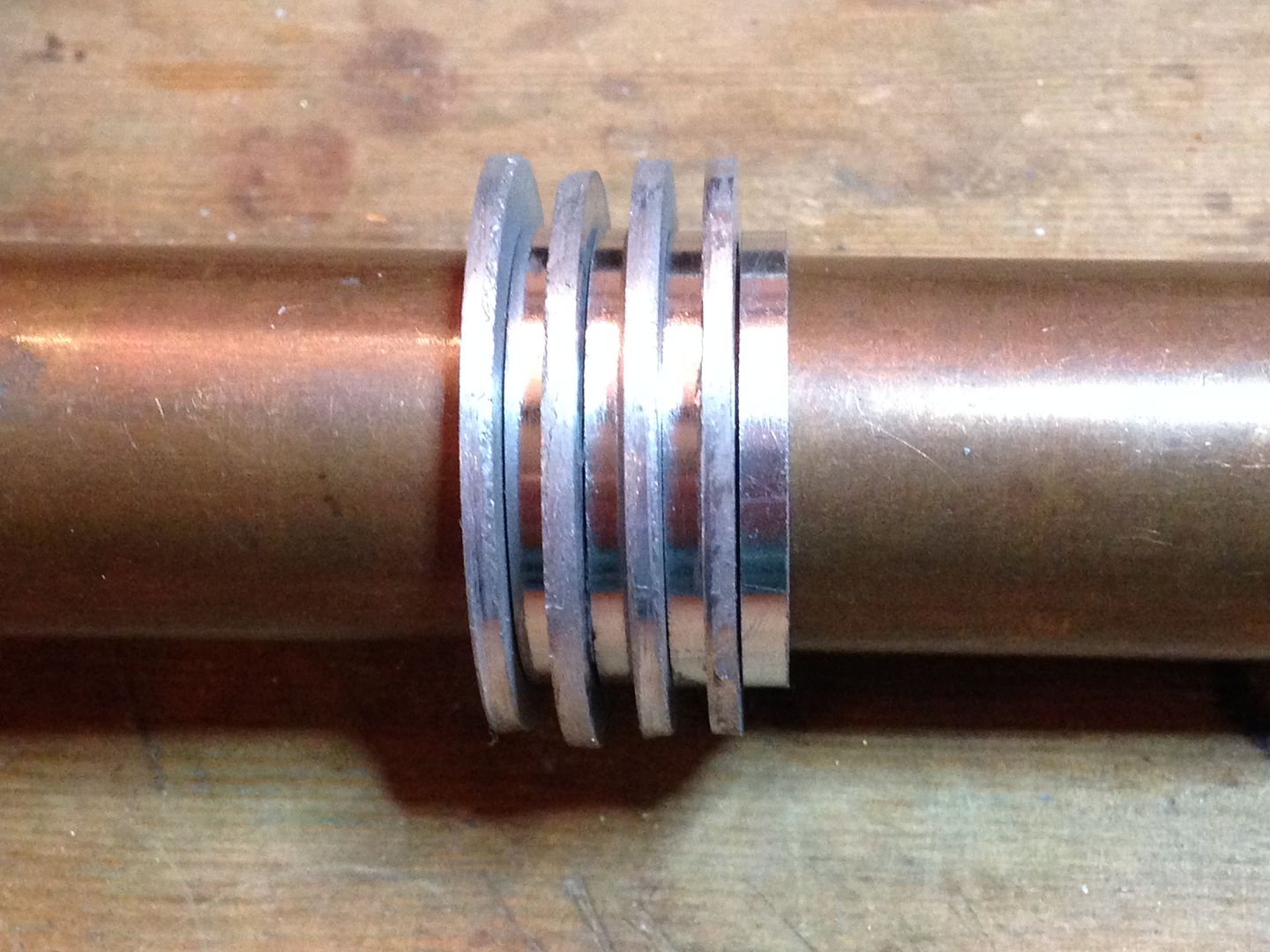

My wrist was bugging me so I did something a bit more fixed. These are the spacers that go between the fins.  They’re a bit uneven in width but this is how they work with the fins.

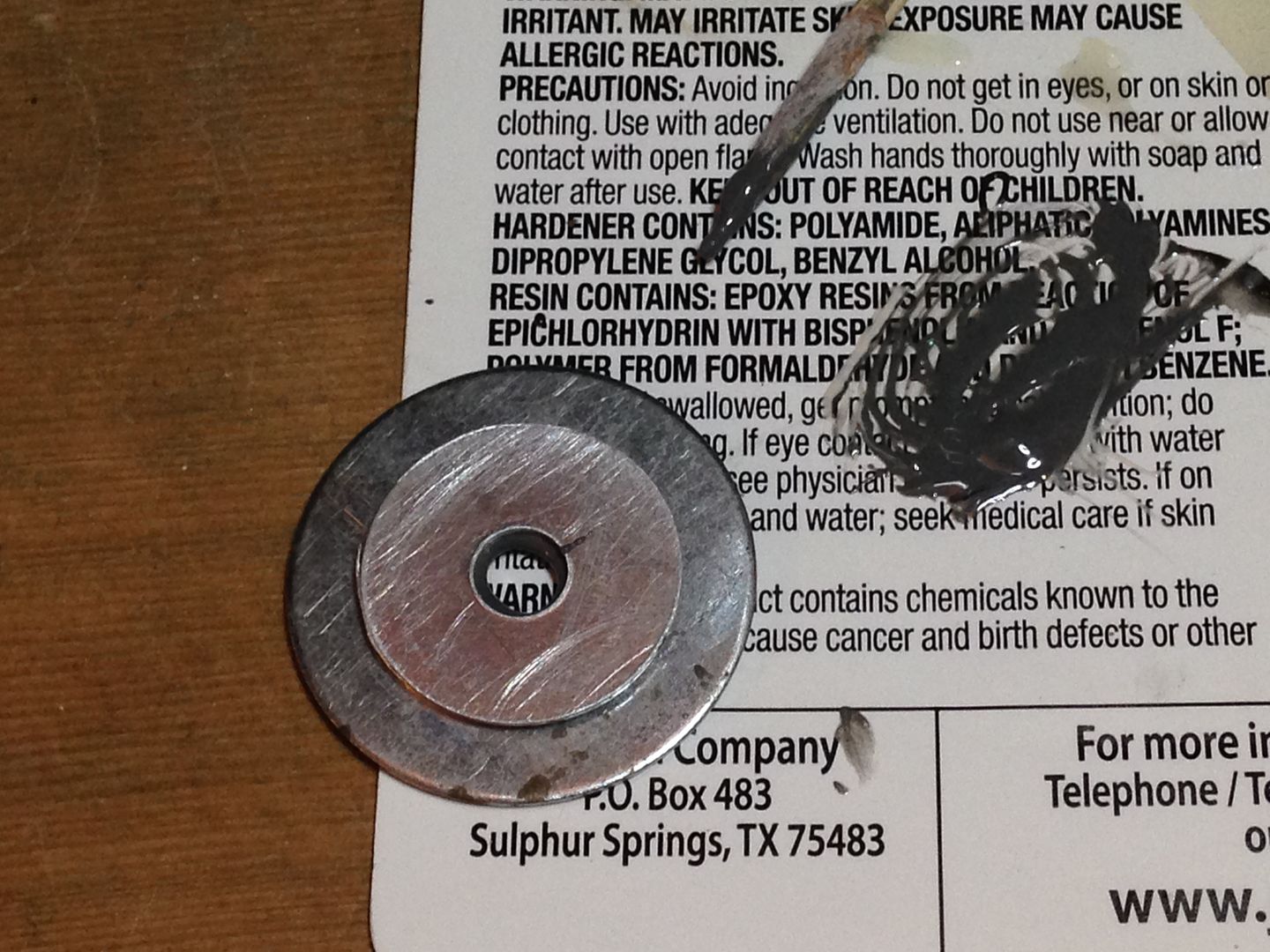

They’re a bit uneven in width but this is how they work with the fins.  To get the spacers the right size I made up a jig with the cut out from one of the fins and a fender washer.

To get the spacers the right size I made up a jig with the cut out from one of the fins and a fender washer.  I’ll put a piece of tape on the smaller disc, the spacer fits around it and when I’ve sanded through the tape the spacer will be just the same thickness as the fins (1.5mm). The fins also need some work. The center hole is just a tad small and not well centered on all of them.

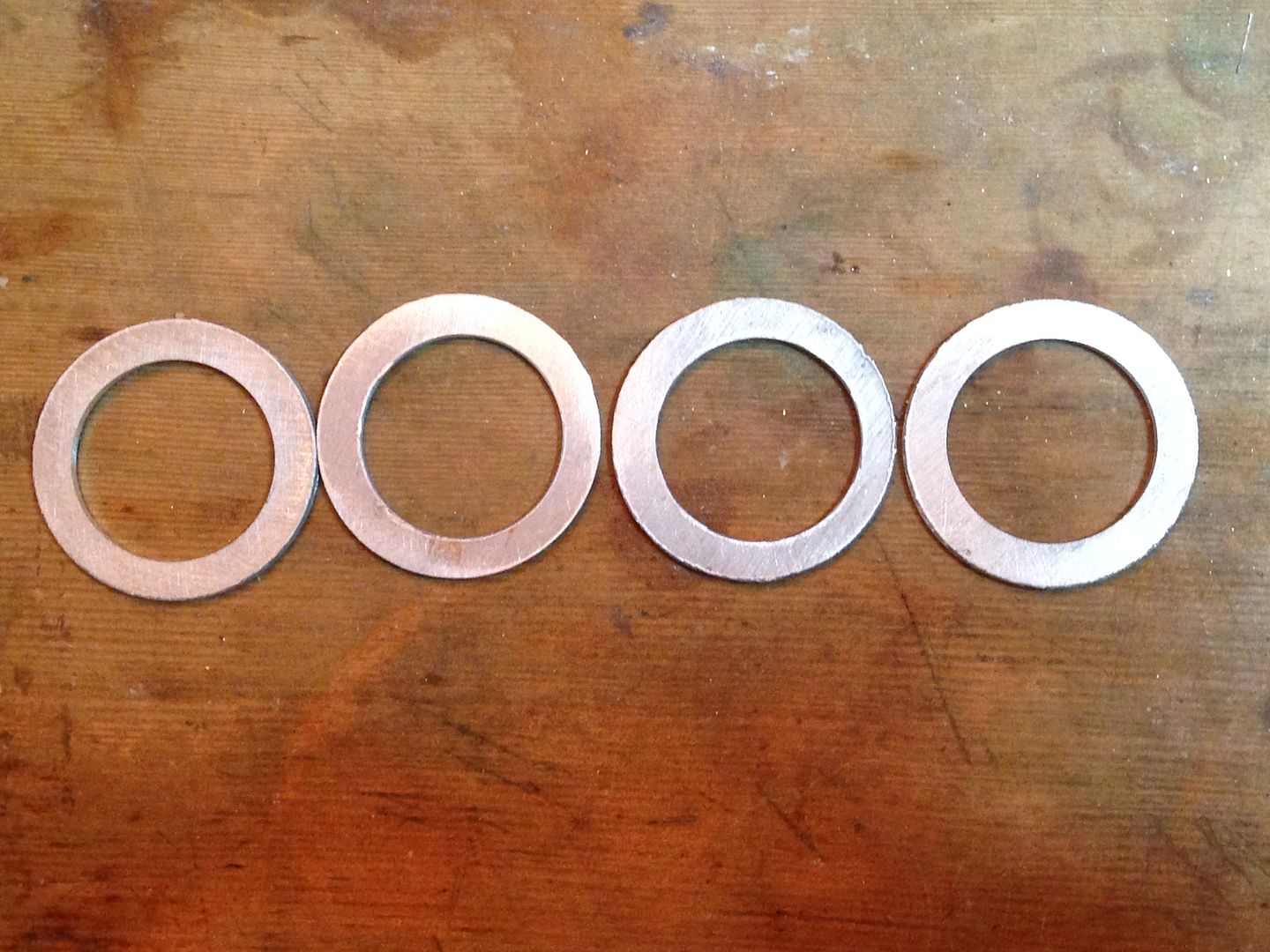

I’ll put a piece of tape on the smaller disc, the spacer fits around it and when I’ve sanded through the tape the spacer will be just the same thickness as the fins (1.5mm). The fins also need some work. The center hole is just a tad small and not well centered on all of them.  First I’ll Dremel the hole a bit in favor of center and then ream it out to a snug fit on the copper core. After that I’ll polish the flat sides. The edges will get evened up after it’s assembled.

First I’ll Dremel the hole a bit in favor of center and then ream it out to a snug fit on the copper core. After that I’ll polish the flat sides. The edges will get evened up after it’s assembled.

Polishing and sizing

Its good to see you back at it RBD. I love your creativity with the cutting of the fins. ![]()

Wrist is improving slowly now which is a change from the first week but still have a difficult time turning my hand with only about 45 degrees without pain vs 180 for the left. To sand I’ll have to hold the plywood and sandpaper up on edge nice I can’t turn my hand palm down. That or do it left handed. Probably both.