If i want to someday build an XM-L2 on copper high amperage light, i want the best heat transferring compound, so please toss in your suggestions

Arctic Alumina or Fujik

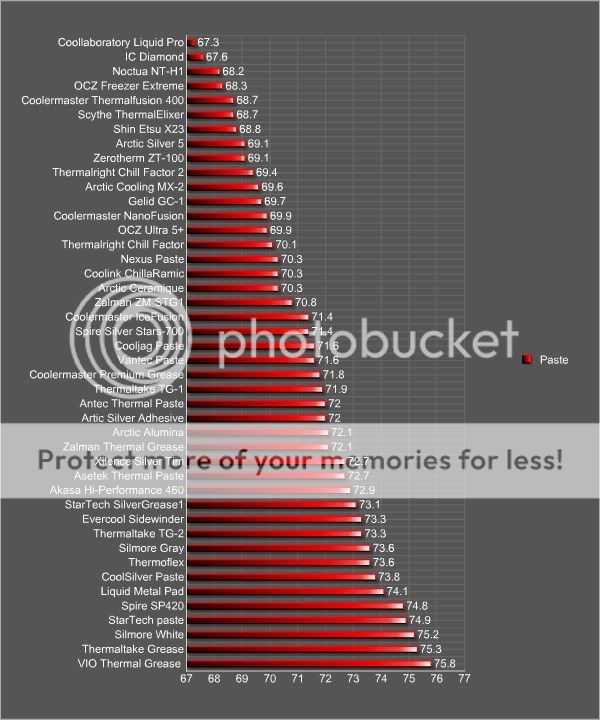

If you can screw it down then a good cpu thermal paste will probably be the best.

If it also needs to stick it there then I couldn’t say its the best but Fujik does the job well. It will cure like silicone if you ever want to remove it as well.

No and hell no.

Look up Parker Chomerics, PPTk recommends them and I had good luck with their products for an internship project.

Wakefield deltabond 155 .

.

If the copper and the heat sink are lapped and the two bolted together, then a good thermal paste would work fine.

Look here: https://budgetlightforum.com/t/-/11451#comment-233314

PPtk says Wakefield for adhesive, Parker for grease.

And like OL said, lap the mating surfaces. The condition of the mating surfaces will impact performance more than your choice of compound.

Fujik(BAB 900) is 0.88W/m.K, that is poor to say the least.

Arctic MX-2 is appreciated in the CPU world. It does not have a curing time like AS5. But as will all thermal compound greases you need pressure for the best performance.

Shin-Etsu MicroSi G751 is probably one of the best I’ve used.

Does anyone here actually use screw for the star? Just curious. Any good tools for threading?

I don’t myself but you can get a basic tap and die set for about $15-20, a good set could cost in the $100s.

I’ve never needed a tap to put little screws in aluminum…just use the screw as you would a tap.

Copper is a different story, and trying to do that same thing is a good way to shear the head off a screw and leave the body in your hole |(

anyway, they’re cheap enough individually to be worthwhile. pick the screw you’ll use first….

http://compare.ebay.com/like/390456861791?var=lv<yp=AllFixedPriceItemTypes&var=sbar

I once thought this idea:

If you have a Copper LED star and Brass pill - maybe can use the soldering between them? It has a much better heat transferring.

If anyone has tried it? ![]()

I’ve been planning to.

but, I don’t think it has better heat transfer than well lapped parts

it does preclude the need for glue or screws though…

I vote for toothpaste - cheap, clean and minty fresh.

I almost always lap my stars+base, then screw them down (usually 4-40 taps and screws). Thermal transfer is so good that I struggle to solder the wires onto the star. In this situation, thermal pastes are a much of a muchness - the cheap chinese stuff seems to work as well (qualitatively) as the Chomerics sample I got. However, the Chomerics stuff is much easier to apply and spreads out more evenly, so if you can sweet talk them into a sample go for that.

No idea on adhesive thermal compounds though, as I’ve never used them.

The LED is fixed to the star with solder, so that shouldnt be a problem. ;)

not sure what you mean.

adding another layer of solder (low thermal conductivity vs aluminum, copper and brass) isn’t going to improve anything

there are real world tests of the two configs (mated parts vs soldered parts) that can be found with google…

anyway, if you have a brass pill, skip the pcb and solder the led to the pill…