I’m just after members thoughts and experiences on what there recommended current draw and favorite drivers are for this led.

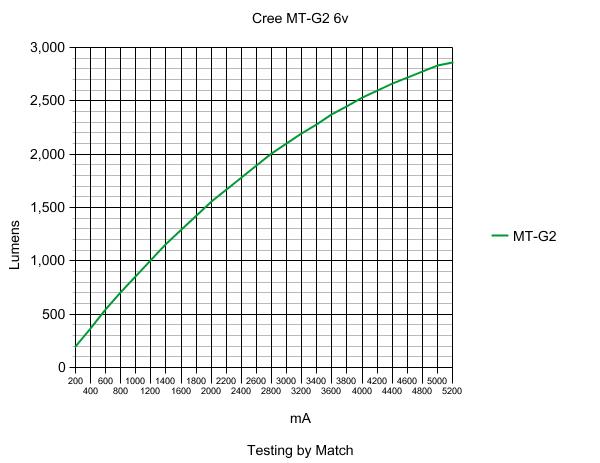

3A is already a lot of light. a lot. It will take more, but heat starts to become a real problem. if you can manage heat (really well)… 4 to 5A is very doable.

PPtk

Thanks PPtk. The plan is to put it in a Defiant C3 with a similar set up to this one.

It will be interesting to hear dthrckt’s input since I think he has driven it the hardest so far. I’m driving at 4+ amp with good heat sinking. It seems to be handling it fine and that it can take more. Using the Manafont “3T6” driver which has the good memory, but blinking modes too. For my app, I want to have the SOS mode available.

Before I got the Sinkpad, I was driving at 3.8+amps and the beam had some blue in it. I’m building a copper pedestal to mount direct on so that I can get the emitter to the right focus in the reflector. Traditional stars will be in the way with this big emitter and a reflector.

EDIT: The above readings are at the emitter using a good DMM that can read up to 20A, but using stock leads. The leads are quite thick, but I figure that the handheld connections and all should be creating some resistance. That is what the “+’s” above are for.

If i had your lathe, I’d make a copper pill like the one pictured, but when you face off the surface you’d put the pcb, leave a 6.0mm diameter, 2.0mm high pillar and solder the mtg2 w/ no pcb directly to that. Its big, so soldering the leads directly to the emitter is even easier than an XR-E.

Then use this driver - http://intl-outdoor.com/9a-3mode-5512v-circuit-board-p-561.html

I’m not sure what increase in output to expect (vs the light that I built w/ that driver and mtg2) but I’m quite sure you’ll find the result absolutely stunning…

Or, if the pill is already made, you could press in a 1/4 copper round. Even better, 3/8” and machine 2 sides down to 6 mm. That way you get more surface contact. I think the height will depend on your reflector. This is the approach I’m taking because I don’t know the height until I actually see the beam working.

You’d be ok w/ the sinkpad brand mtg2 pcb and 5A or so at the emitter, but you have to make sure there is very good contact between pill and emitter. If there is poor contact, the dome will bubble at the emitter. If there is (minimally) adequate contact, a light meter will reveal a big sag in output in the first 30 seconds…

One other note about that driver - personally, I wouldn’t consider using it unless it is potted.

anyway, pptk was right, 4-5A is very doable, and w/ great care, so is more

Who has pcb, better, copper pcb for the MT-G2?

i’m not aware of a copper one, but sinkpad makes aluminum mtg pcbs. maybe someday they’ll get popular enough for a custom run of copper pcbs…

Or, if the pill is already made you can send it to me and make another like dthrckt suggests. ![]()

Sinkpad might even send you a couple alum versions as samples . . check MTG2 interest box if you haven’t asked for samples via their website yet.

You can also put copper under “Other”, but that will probably only be XML and XPG versions already available if you check those boxes, too.

Damn, wish I would have thought of that one.

1/8" copper plate...

Thanks guys for the input If I read this correctly there is no copper sinkpad available for this. Thanks for the suggestions on mounting it on a pillar but with all my electronic skills I would kill the led and I don’t really want to do that with $20.00. So its 5 amps max and lots off luck. Cheers.

Would an mtg2 fit on an xre board? Not got one to measure (xre), but looking on the cree data sheets it does look possible……and you might be able to get a copper sinkpad sample too!

I have a bare Cutter 20mm board and I'll have to desolder an XR-E from a 3-up board, but I can check that fairly quick.

How quick. I’ve got 10 minutes before I go to work? ![]()

Hell, I don't even need to desolder the XR-E to see that it'll work, holding them next to each other is enough. The MT-G is of course wider, but the spacing of contact-center pad-contact is exactly the same. A little of the MT-G2 will hang off each side but that shouldn't hurt anything.

It will work, but sinkpad doesn’t make copper XR-E boards (or aluminum XR-E, last time I checked), and if you were going to use an aluminum pcb, you might as well use their MTG pcb, since like all their pcbs, the center pad has no dielectric layer.

Ooops I didn’t check to see if they did a copper pcb (or not)! Sorry folks