08/22/15 - the end............... and a new beginning for someone else at BLF.

08/13/15 The lathe is finally ready to run.

07/31/2015 - I felt this should be here, as well as in the contribution thread.

To everyone who has made this thread possible, I say, Thank you for your contribution.

But words are not enough to explain the feelings I have. Words can never be enough to express those feelings. They are too many and too varied to describe, so here are a couple of quotes that might help explain.

“I would maintain that thanks are the highest form of thought, and that gratitude is happiness doubled by wonder.” –GK Chesteron

“Feeling gratitude and not expressing it is like wrapping a present and not giving it.”– William Ward

“Appreciation is a wonderful thing. It makes what is excellent in others belong to us as well.” -Voltaire

"In ordinary life we hardly realize that we receive a great deal more than we give, and that it is only with gratitude that life becomes rich." -Dietrich Bonhoeffer

“Forget injuries, never forget kindnesses.” -Confucius

“In everything, give thanks.” -1 Thessalonians 5:18

"By the way, I’m wearing the smile that you gave me." -Unknown

With Thanks to members of this forum, I have:

A Grizzly 10 x 22 Bench Lathe

A Shars AXA Piston Type Quick Change Tool Post Set

A Grizzly Indexable Carbide Tool Bit Set - 3/8"

A Grizzly External Threading Tool Holder - 12mm x 16mm Right-hand

An Internal Threading tool holder Right-hand

A Right-Hand boring bar

Inserts for ALL of the tooling

A Shars 3/4" Drill Chuck with Arbor

SAE and Metric Screw Thread Pitch Measure Gages

Three Knurling Tools, (I like Knurling)

An Altai Center Drill/countersink combined

A Live Center

An Expanding Arbor Set 8 Pc.

An 8" Digital Caliper

A set of 3 Digital Micrometers

A set of Telescoping gauges

A Grizzly Magnetic Base/Dial Indicator Combo

ISO 68 and ISO 32 oils for the Lathe, along with Tapping/Cutting Fluid

Enough funds to go buy Rod stock in Aluminum, Copper, Brass and Plastic

And don't forget, A hand made Lathe bench

EDIT: 08/03/15 - Due to the additional money coming in and due to shopping for the lowest price on items, I have also purchased a larger Drill press and a portable band saw, that I will modify into a chop saw style band saw.

Also, there are over 25 new, or as new, flashlights sitting in the shop, waiting for me to touch them all and mod them, so I can re-sell them.

I'm sure I left something out.

Oh, a heart that is so full of humility & admiration for the kindness of everyone here, that it is hard to keep the feelings inside my chest.

No more words to say now...

Well, not exactly, LOL.

This will be a big learning curve. Before all of this happened I had touched a lathe maybe twice in my life and not knowing a thing, I made a couple simple parts out of it, along with slightly damaging a couple HSS cutters and enraging a tool maker, when he found out the night guy had played with the Lathe..., more than once.

So, it will take time for me to learn how to use the lathe. It will take more time for me to practice what I learn, to be proficient. It will take time to turn ideas into something that can be made, or can't be made. Lots of time, plenty of time...

Through all that, you will get to watch, if you desire. You will get to see first hand when the Lathe arrives and when it's mounted in place. You will see when it is first inspected and when I first use some of the terminology, by naming the parts of the lathe. You will get to see and hear the first turn on and the initial break in and you will get to see and hear all of the trials and tribulations of making flashlights out of chunks of metal and a machine. That is part of my thank you as well. It will be an ongoing thank you and an interesting one, I hope.

Just be patient, more patient than I will be, as I wait out the heat of summer, while itching to be in the shop, playing with new ideas.

Again, Thank you All.

Justin

--------------------------------------------------------------------------------------------

I figured I would start a thread about the progression of the lathe project. It's the least I can do. First video is really short, but don't get used to it, you know how much I love to talk.

The bench will be wood. It saves a bunch of change that an be used elsewhere, like buying rod stock or tooling. The pile has mostly 2x4s with a few 1x6s. The top will be 1x6 boards, with 2x4 boards backing it. Six legs, four of them under the heavy end and two under the light end. Supports near the bottom of the legs, to keep them steady. I plan on a hole in the center of the top, so chips will fall through into a box. Thanks to VB for telling me that one, or I would not have thought of it.

I plan on making this week-end a torture test, making a bench in the garage. The temp inside today is 102F. Just a little warm. Maybe I will sweat off some of this old age fat.

More when I get more.

----------------------------------------------------------------------

07/25/15 Update

So I got up at around 5:30AM and went to HD at 6AM, to get some screws that I "thought I had" and came back to break out the Table Saw... Well, it's a table and there's a saw... Hey, it's "old school",

MRsDNF said something about marking twice, or cutting twice, or something like that. Well, I always mark twice, as a saw guide. That way I don't have to think I just cut between the lines. I can't read between the lines, but I can cut between them.

The first ever O-L Selfie!  It's 90F in the shop already and I always sweat like crazy. I knew you wanted to know that.

It's 90F in the shop already and I always sweat like crazy. I knew you wanted to know that.

The frame for the table top is laid out. Not screwed together just yet. The left side is for the heavy end of the lathe. A support will be on either side of the hold down bolt area.

First leg is set in place. I like to test stuff out before putting it together for real. This table will be 36" tall and should put the lathe where I can work on it without bending over too much. Easier on the back that way. Six legs total.

The wood is cut for the bottom frame that will go about 6 inches up from the bottom.

Time to go take a break and sit under the fan for a while. Hopefully, I will be back later.

---------------------------------------------------------------------------------------------------

07/26/15

I am working on it, really, but just slowly. The top frame is glued and screwed together. The legs are glued and screwed together, but not to the top yet. I just set them in there, to give you an idea. I still hope to get it done today, but reality suggests tomorrow at the soonest.

I will be ordering the lathe Monday, as well as the majority of the tooling.

Ok, it's almost finished. The top boards are not screwed down yet. I have to take the hand saw and do a little planing of the legs on top, but I should finish that in the morning. I think I will add Plywood on top of that and maybe even a piece of Diamond plate on both ends. Don't know for sure yet. I'm not worried about the sides any more. Adding the bottom run of 2x4 made this thing rock solid. The adjustable feet should come later in the week.

And, so far, it's still under $100 for the table.

-------------------------------------------------------------------------------------

07/27/15

I believe the table is done. I haven't decided on the diamond plate yet. The plywood is pretty tough as is. I know, I cut it by hand. Anyhow, it's about too heavy to pick up, so it ought to be about right for the lathe.

Anyhow, it's about too heavy to pick up, so it ought to be about right for the lathe.

I added plywood on the bottom shelf too and boards on the back side. It won't go anywhere and it won't vibrate either. Wood is a good dampener for that.

Oh, I ordered the lathe this morning! How it works is, you order, then Grizzly contacts shippers, to find out who can fufill the order, so I wait a couple days to hear back. Nothing is paid for yet, not till the shipping agreement is reached. In my case, I don't expect a shipper will agree, since no Semi's are allowed in our 55 and over community. Even if one got in here, there's no place to turn around. The driver wouldn't like that. I'm following Dan's lead and when I know who the shipper is, I will call them directly and talk with them about it. I figure if everything goes right, it should show up next week. I won't order anything else till I know about the lathe.

Another short video of the bench in place and the Diamond plate added.

---------------------------------------------------------------------------------------------

Not real good at duct work, but it has a pan now, to guide the chips into a box below. Still waiting for something from Grizzly about shipping. Nothing has been ordered yet! Called again today. Hope to hear something positive, but not counting on it. Grizzly seems to be too big to know what they are doing.

-----------------------------------------------------------------------------------

07/31/15 - Good News! Grizzly is "Supposed to" ship the Lathe today!

I ordered just about everything and purchased what I could, locally, like some necessary measuring instruments.

Calipers, Micrometers and some ID gauges. I rearranged the old tool box and took out all of the socket sets. Put them into storage, as I do not work on cars any more. I can still get to them easy enough. I happened to have a large section of the foam made just for tool boxes. so I lined a few drawers and cut out for the instruments. At least it looks professional.

------------------------------------------------------------------------------

08/02/15

Made up some side boxes for holding the tool holders and other accessories. I will also hang some hooks from the other end, for the gears.

------------------------------------------------------------------------------------

08/03/2015 - Let there be light.

I just happened to have some leftover 2x4s and a 4' Fluorescent light hanging around. Not only can I hang the light from that monster, but maybe the wife too! The uprights should also work as a support for the backplate from the lathe.

-------------------------------------------------------------------------------

08/05/2015 - Time to get the car out of the garage and clean the floor, for the new arrival. I sure hope it shows up tomorrow. After the disaster with the drill press, I don't know.

I mentioned that I bought a drill press didn't I? Well, that was a big fiasco. I bought it at sears online. It was $218 on sale. It was supposed to ship to me, from Mesquite, TX. So it did, to the wrong address and after trying to deal with the non-english speaking Sears reps, they told me I had to contact UPS myself!! Ok, so I did that, only to find the drill press had been shipped right back to Mesquite, TX. After another frustrating round of non-english speaking Sears reps, I canceled and took a refund and went down to Harbor Freight with my 20% off coupon.

I wasn't going to buy a drill press. I was going for the Flex shaft Rotary grinder, AKA - Big Old Foredom Clone. So, I had to have a manager find it and while he was getting it down, I mentioned that I wanted one of the drill presses, because of the Sears screw up and one of the HF ones is exactly the same drill press, except for the color. I told him that Sears had it for $218 and couldn't he cut down the $269 price there? Well, he did a little figuring and told me the 20% off coupon would take it to around $216. I said great, but what about the other item I am buying. He said I could always go home and come back with another coupon and they would honor it and I said, "Why don't you just go get one out of your desk drawer and give it to me now and do both deals. A sale is a sale and if I walk out, I'm going to Sears." So he did and I got both items for 20% off and in the long run, it's a better deal, because if anything goes wrong, all I have to do is take it back, instead of dealing with the Sears Weenies!

The high speed grinder is basically just a motor with a flex shaft and a chuck on the end, to take bits like a Dremel does. It's just that is can run faster speeds and has a higher torque, so it will do bigger jobs faster. The bit holder handle uses a chuck just like a drill press, with a chuck key, so it can hold the bits much better too. Lots of new stuff in the shop these days.

The wife asked me when things were going to go back to normal... I didn't reply, after all, what could I say that wouldn't piss her off.

---------------------------------------------------------------------------------------

08/06/15 The lathe has arrived and the first part of the video is up.

Well, I told you there would be a lot of videos...

And Photos...

USP shows up at about 11:00 AM.

Yep and I'm right there riding the guy's ass. Get that box off that truck, Little man.

I'm tellin ya, if ya don't set it right over there, I'm a gonna whoop ya with this here 2x4.

I was just jokin round.

Time to inspect for damage

and again

I knew I would find some if I looked hard enough!

Ok, I will sign, but I got to write down the damage. Hey, watcha lookin at over there on that table where all the flashlights are?

Hurry up and give me that receipt and move along.

'bout time.

Finally, alone with my baby!

Hey, don't that look like a girl lathe, I think she's a winkin at me.

Baby, I got half a mind to climb right on in there and.... Oh, the wife's still takin photos, well later then.

The Grizzly G0602 10x22 lathe.

----------------------------------------------------------------------------------------

The lathe is now in place. It went very well. No screw ups at all.

Time for a break and early tomorrow morning, I will level it.

---------------------------------------------------------------------

First Lathe Mod... Oh, you didn't think I would leave it stock did you?

The back cover for the pulleys and gears, cannot open, because it is hinged so that it opens towards the wall. There is no room for that, so a mod is called for.

I haven't decided to make it lift straight up, or pull out straight back. If I make it lift up, I have to cut off the lower lip of the cover, so I will probably make it come out straight back and keep the cover intact. I can loose the hinges and make two plates that interlock as the cover goes on. Shouldn't be too hard to do.

------------------------------------------------------------------------------------------------

Long video. some guy rambling on about some lathe. Doesn't sound like he knows much about it.

Told you I would drown y'all in videos. Should I be using another format than Flash? Iframe? Shockwave? Windows Media? Realmedia?

-------------------------------------------------------------------------

08/08/15

No photos, no videos, just an update on status. I spent yesterday afternoon and this morning, tearing down the lathe. I tore down the Compound rest, the crossover and the chuck. The reason was that I found a lot of dirt and tiny metal shavings inside those areas. Up inside the slides of the compound and the crossover and inside the chuck. So, I now have them all back together and they are all moving smoothly now.

The other and bigger issue, is the low speed belt. It was pre-installed on the lathe and I found it to be so tight, that I could not remove it. Even after loosening the mounting bolts for the motor, I could not get any slack. I had to pry it off, as I rolled the pulley over by hand and I will not put it back on. The low speed belt and high speed belt should be loose enough to be able to change to different pulleys easily and there is a tensioner arm, to take up slack. The high speed belt is the correct length and works fine, but the low speed belt is too small. The problem is that these are not regular V belts. They are Z series belts, used frequently in Europe and the UK, but no one carries them in the US and I will not waste money on Grizzly belts, because they will be wrong. I have never found a Grizzly replacement belt that would fit anything.

So, I need to find a UK member and get him/her to go to "The Bearing Company", in the UK and buy a couple of Z belts and send them to me. I will make a new thread post about it. The Bearing Company, does not ship to the US or Canada. They ship just about every place else, but not to the US.

Anyhow, for now, it will sit, till I get belts for it. Just an FYI.

------------------------------------------------------------------------------------------------

08/12/2015 -

Not much going on. I got in the fractional belts and now I can run the lathe, with the replacement belts and use the tensioner, to take up the slack, so it's good to go there.

I also made a little cover over the chuck area. I noticed it tended to sling a little oil, so I thought the cover would keep that from flying into the garage. Probably could have covered the whole thing, but it would be hard to work around it. This one folds up and out of the way.

That's it. I am waiting for parts to come in. I have a drill and tap coming, so I can drill out and tap the base plate for the QC tool rest. I also have some handles coming, to replace a couple of the stock ones, with ones that free spin, like the carriage and crossover do. Once the QC tool rest is attached, I will to some test turning and threading.

------------------------------------------------------------------------------------------------------------

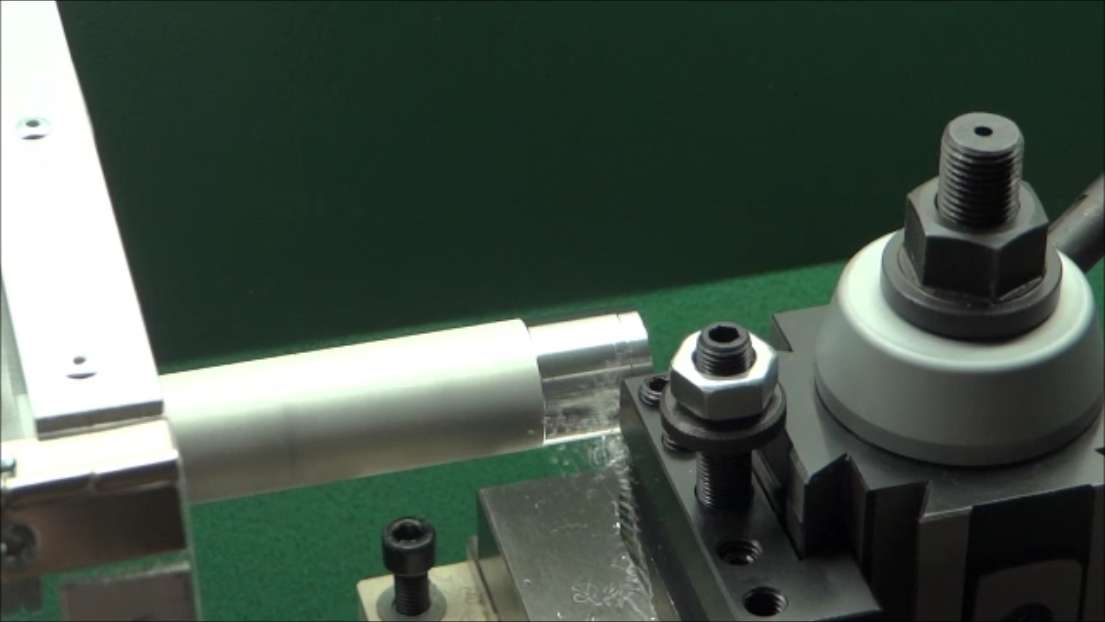

08/13/15 - I received the drill and tap, so I could drill out the bottom plate, for the tool rest. I have done that and now it is in place.

This means, the lathe is now ready to run.

All covered up, to keep it from running away.

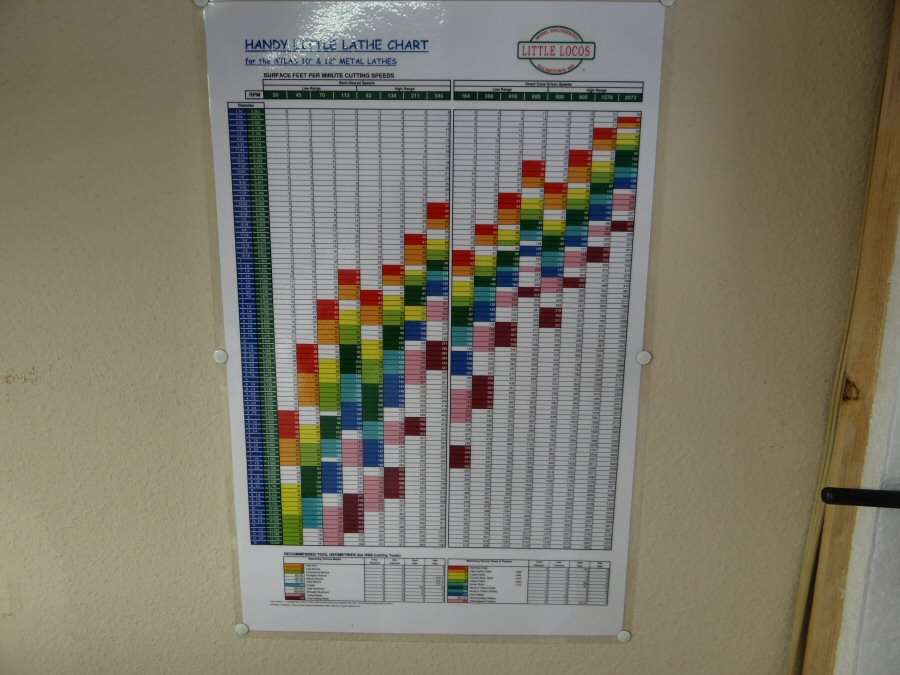

I also got a handy chart for speeds of different metals and different ODs. It's for HSS tools, but I can adapt for Carbide. At least it's a starting point.

Now, all I have to do, is wait for cool weather.

----------------------------------------------------------------------------------------------

You knew I wouldn't wait till fall!

First chips video.

More to figure out. The change gears won't come off the shaft, so time to tear that down. I think this lathe was made on a Monday.

------------------------------------------------------