Edit: DBC-02 became a laser… green light at around 200mW

The light got rebuilt to the point it became DBC-04, and now it has an extension ring in Titanium to allow for an 18500 cell with 1000mAh capacity, which gives 14.11A at the tail to the new XP-L2 V6 1C emitters and a change back to Carclo Quad optics. This allows some 700 lumens more light, at 4122.75 lumens. ![]()

I did the cell addition/change in January of 2017, completed the emitter swap to XP-L2’s November 14, 2017. ![]()

—Hiya hiya!

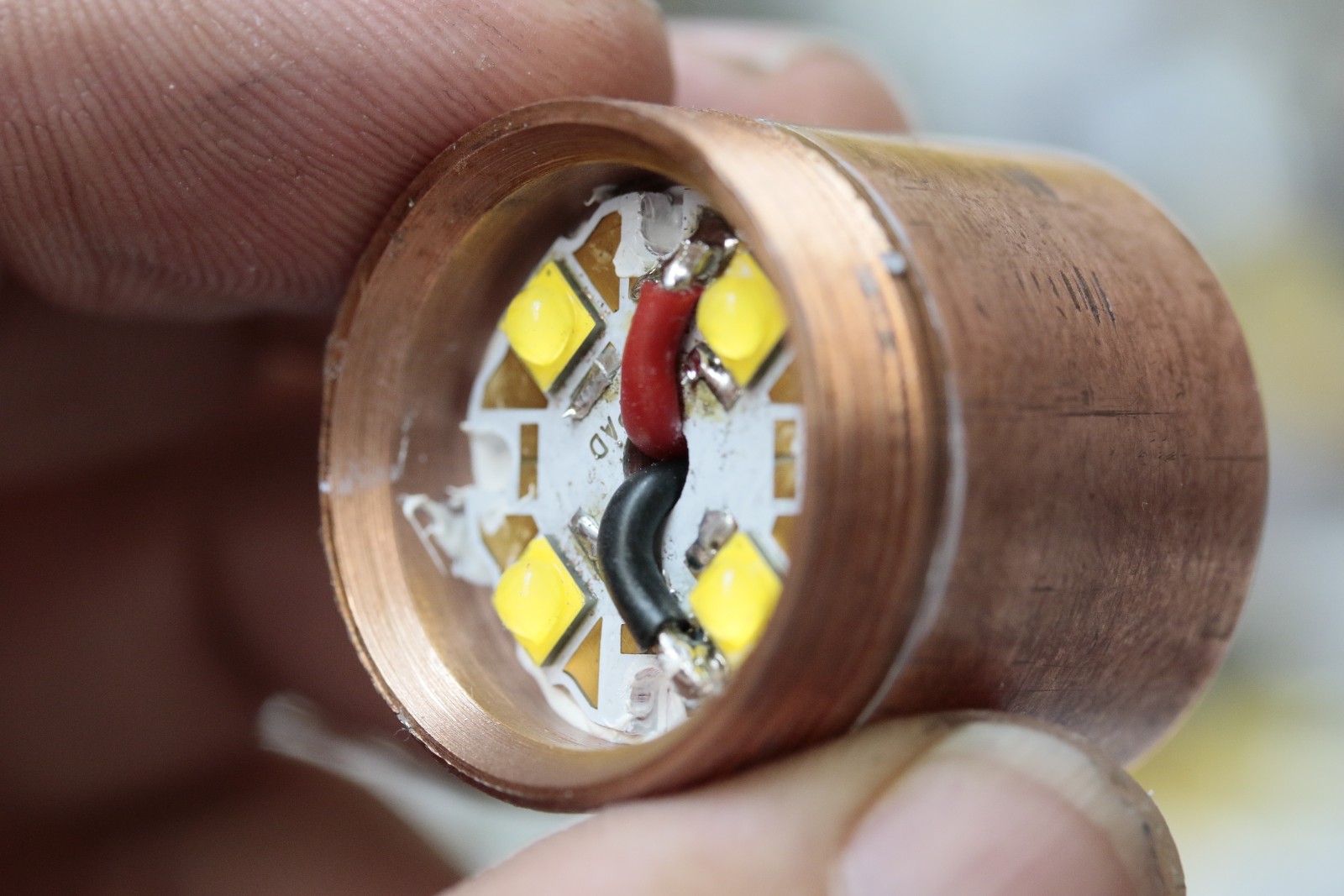

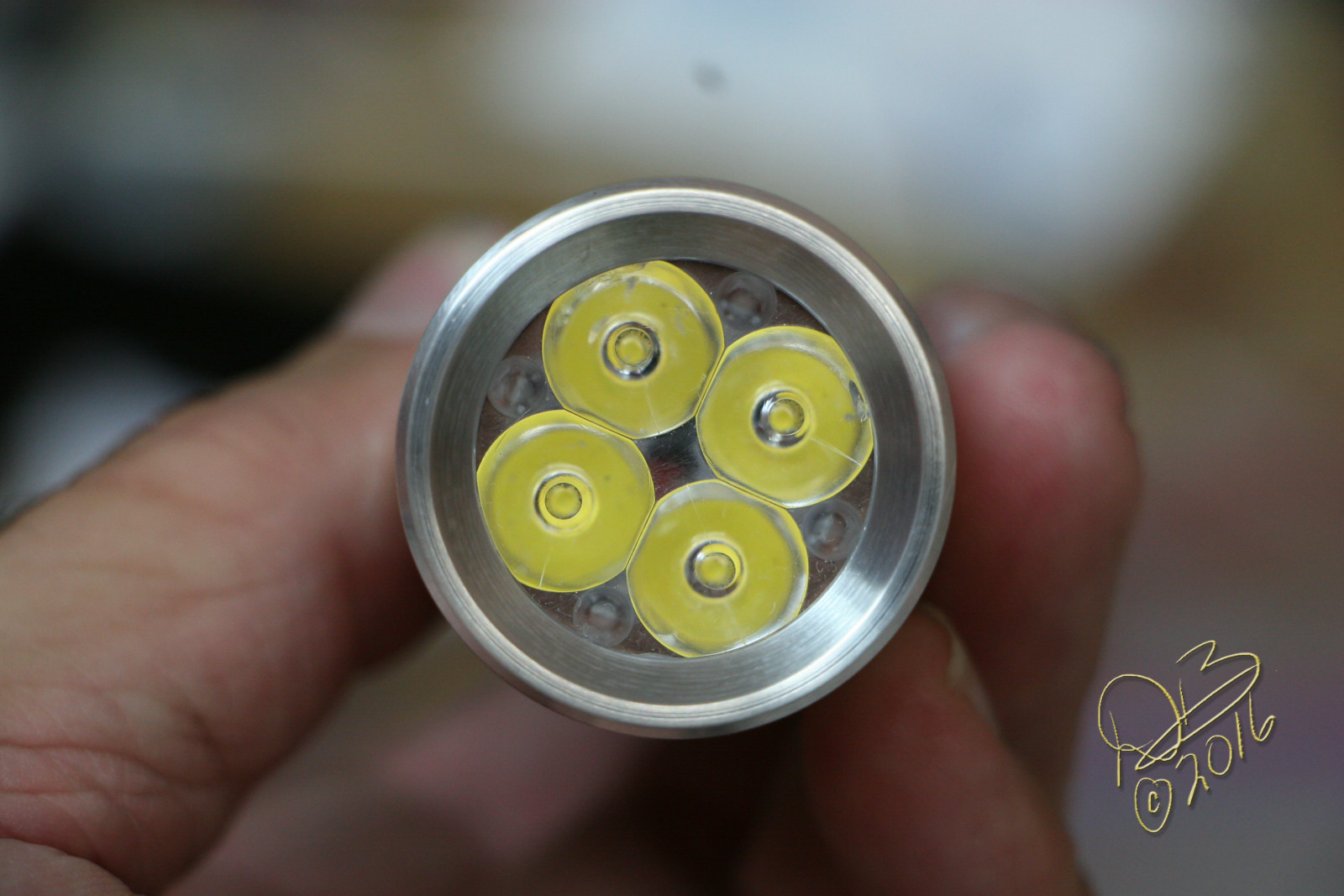

I thought I’d share my second complete scratch build on the lathe, the DBC2 Quad EDC made with Cree XP-G3 S5 3A emitters on a Cutter T-Pad copper mcpcb with Khatod spot quad optics. I made it day before yesterday kind of on a whim. Just went out to the shop with a pocket full of the components and whipped this up initially in about 6 hours. No design, no real plan, it just formed itself as I went along. ![]()

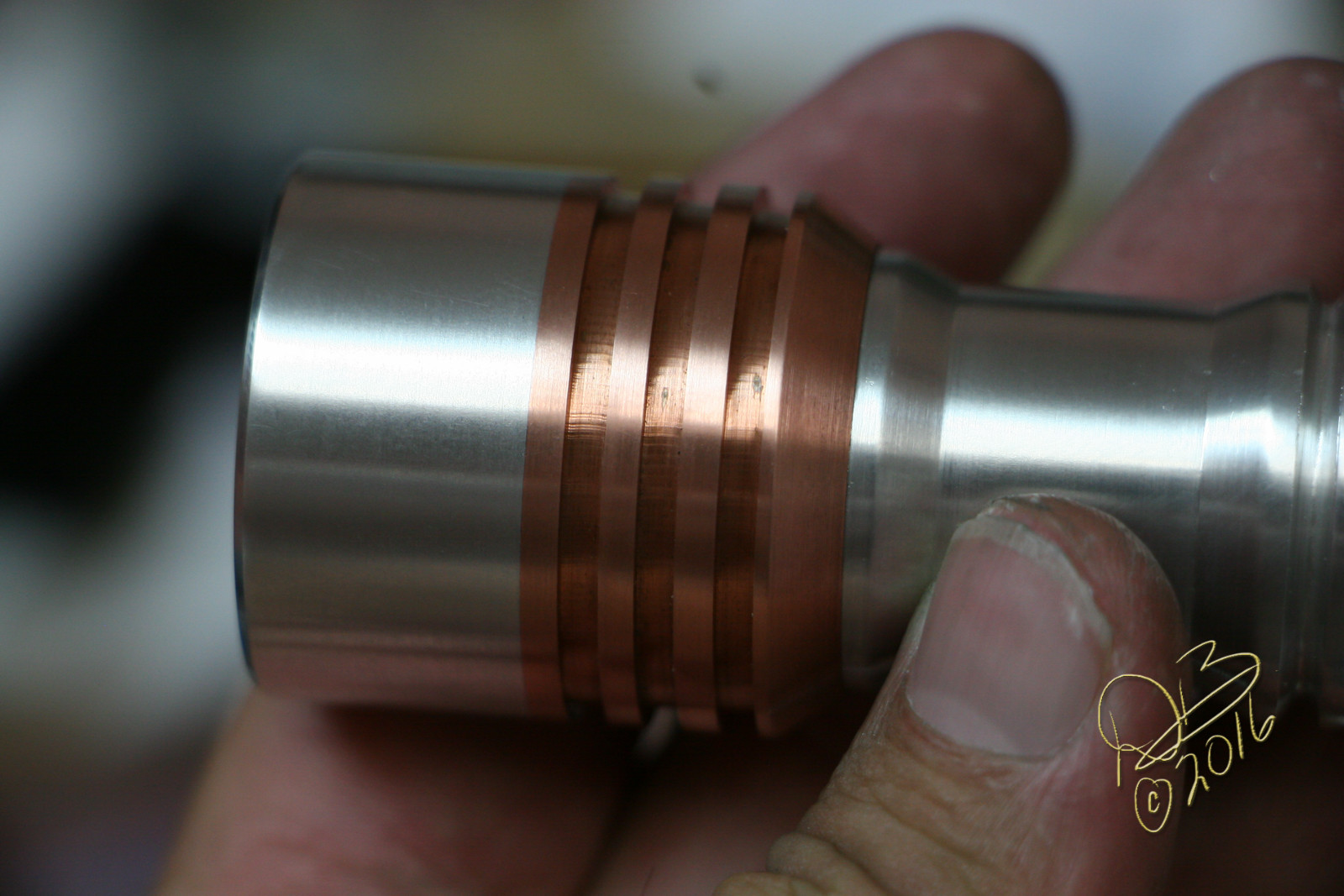

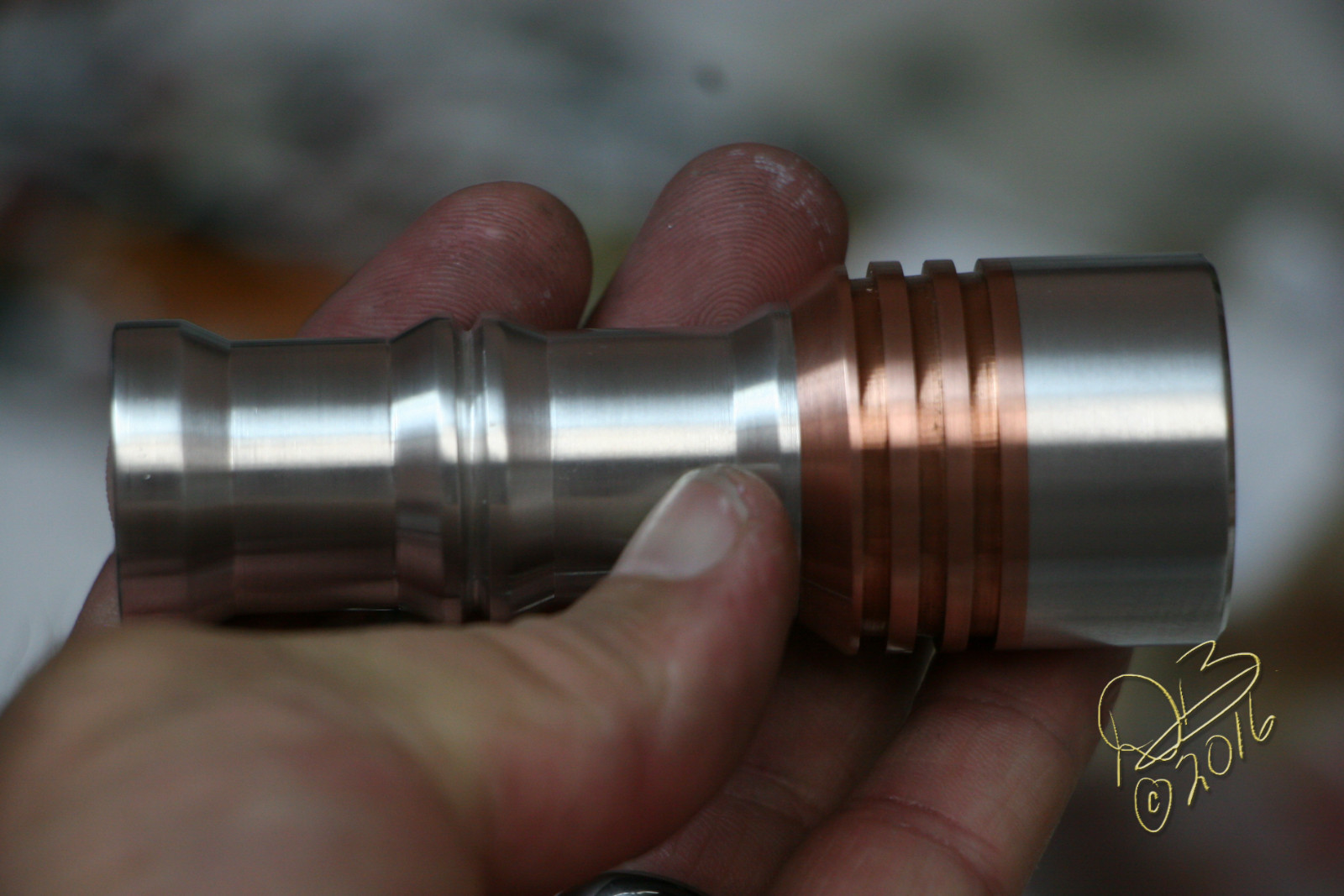

When I got started on it, I had two left over pieces of copper… one in 100% pure that was long enough but not large enough diameter, and one Tellurium Cu that was the right diameter but too short. So I made a 1” pill design with a bezel threaded onto one end and a driver cavity and battery tube threads in the other. Then finned the Tellurium and made it a slip-on. Not optimum, but it worked. ![]()

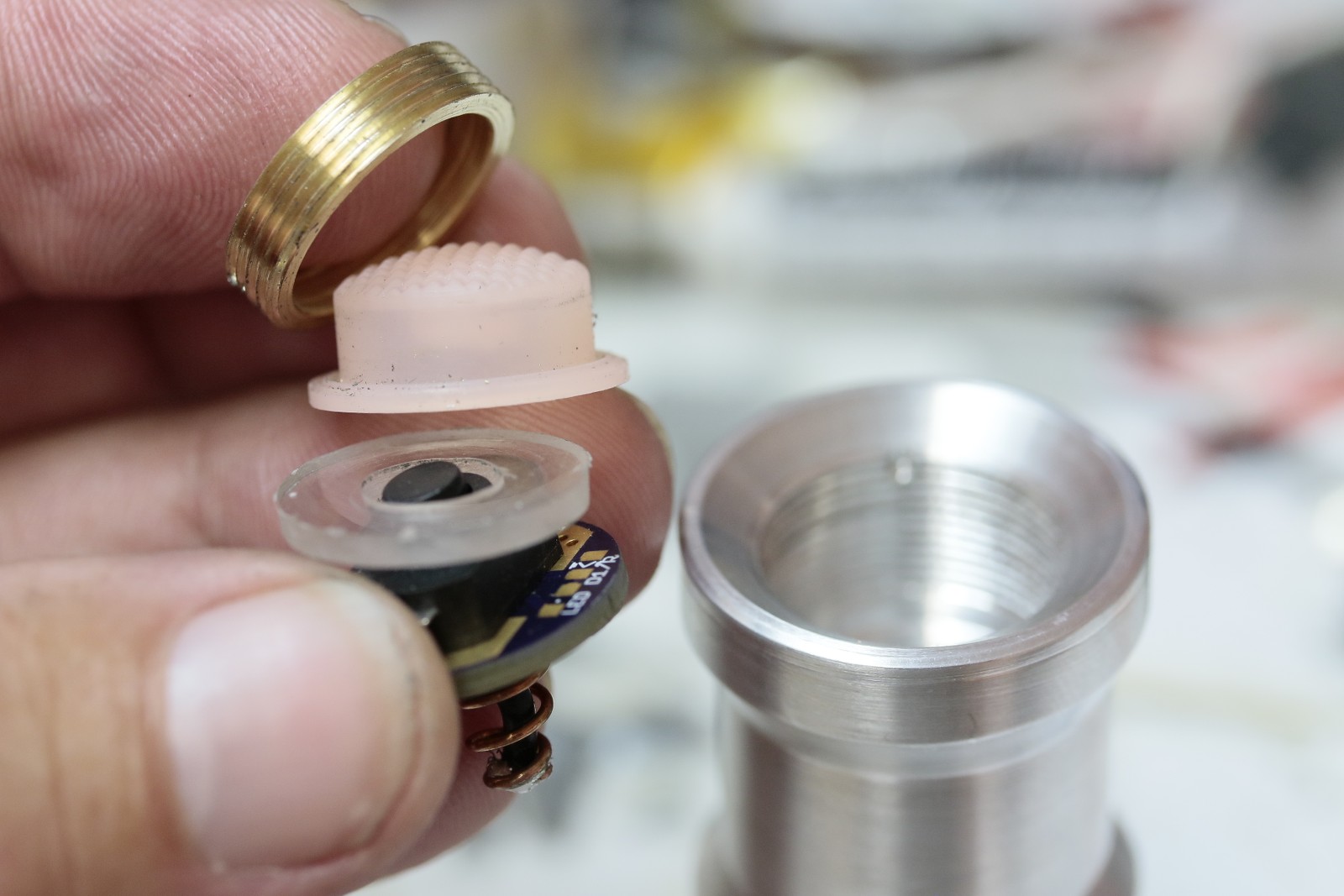

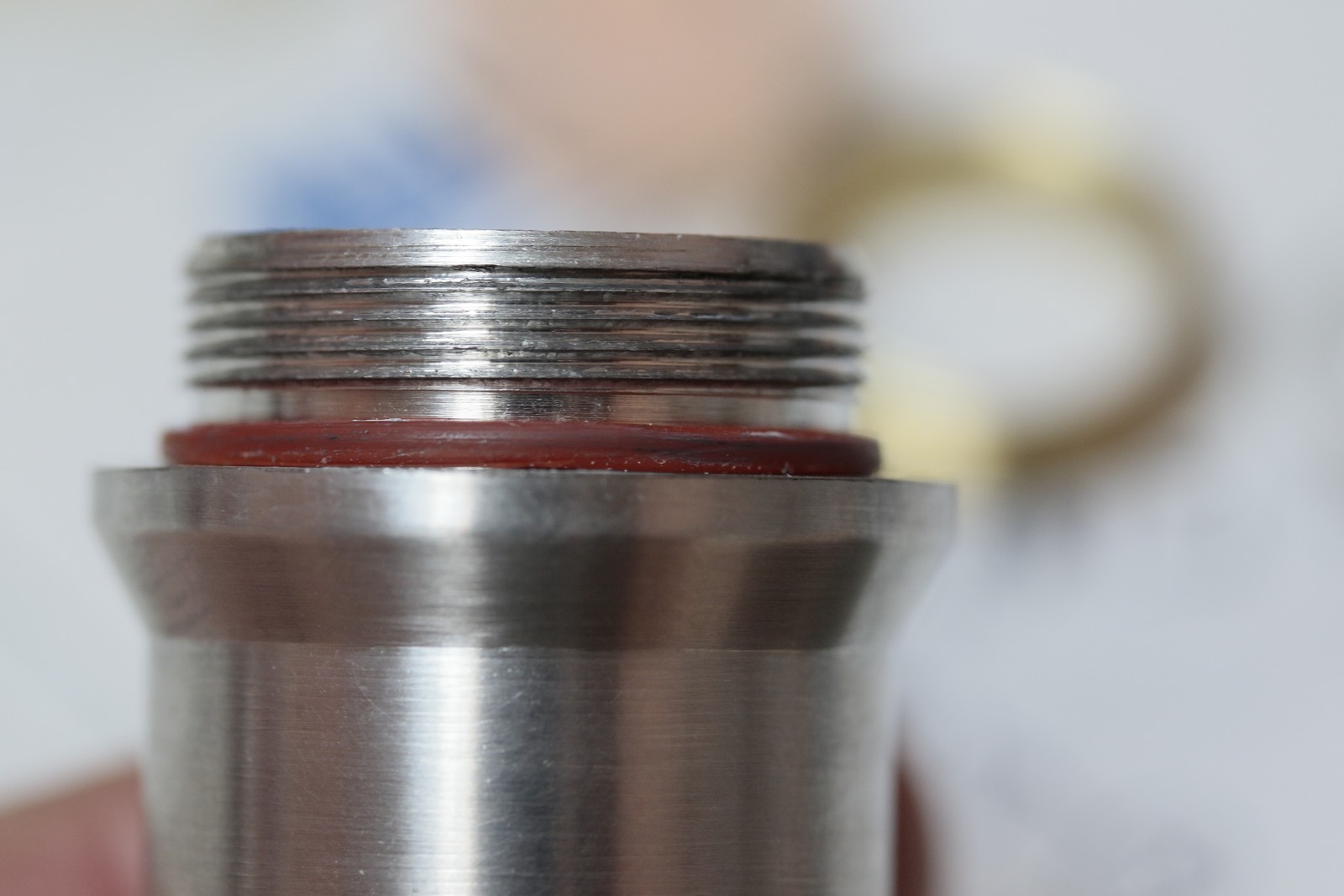

The battery tube is bored to the correct depth, then the switch is put in from the rear and held in with a brass retaining ring. All done on the fly, as it were, making it up as I went along. ![]()

This is a pilotdog68 lighted tail cap board, with the clear acrylic cover piece and a pinkish opaque rubber boot from my X6/X5 lights. I haven’t done the lighted tail cap thing, not sure if I will on this 18350 light.

I had one of Richards ATTiny25 FET+1 drivers with no firmware flashed to it, so I put the latest Bistro firmware on it, wired up with 20ga leads and got some 2250 lumens out the front from the G3’s and a Carclo quad optic. Then I bypassed the springs and got 2515 lumens. This was playing with it yesterday, getting the brass switch ring finalized and all finished up.

The crazy thing is, I did this while coming off a double dose of the sedatives I sometimes have to take. I mostly remember doing it, but the time it took seems kinda foggy. lol Just wandered out there and did it.

Then today, I changed the game plan…

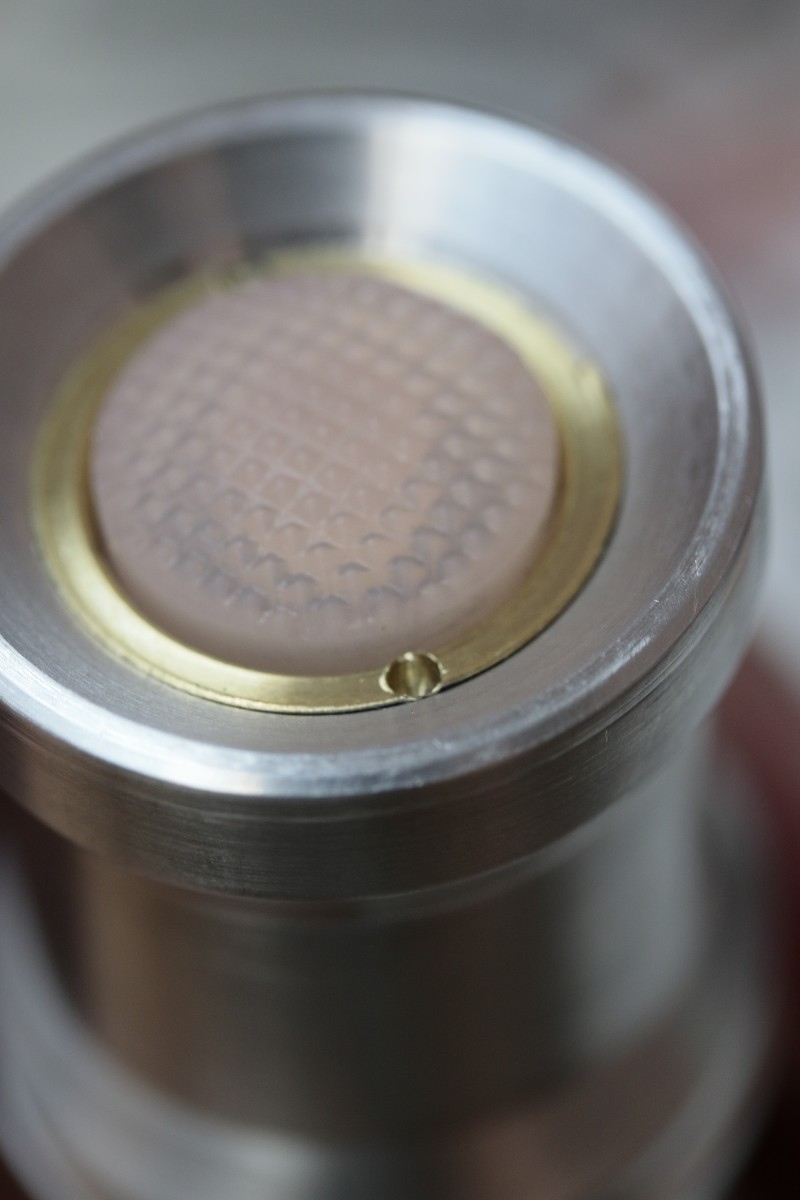

Did a bit of a redesign. Remembered I had the tighter Khatod optics so I redid the bezel and bored the pill to fit the wider optic legs and allow the taller deeper TIR’s. ![]() 2559.9 lumens now, from the XP-G3 S5 3A’s.

2559.9 lumens now, from the XP-G3 S5 3A’s.

I’m liking it, in spite of the extra effort it took I’m liking how it turned out. All in a days work, right? lol So I’ve got about 10 hours into it now. Not bad, not bad at all.

(Edit: For the record, the head is 33mm in diameter, smaller sections of battery tube are 23mm while the raised sections are 28.6mm. Overall length is 92.8mm. It weighs 181 grams with an Efest purple IMR18350 cell installed.)

Before, with Carclo quad optics…

After, with the Khatod…

I really love how two metals merge when machined together…

All in all, a fun little light with some punch, and plenty of copper to handle it. ![]()

Thanks for checking it out, one of these days I might actually get good with the lathe and start doing things “right”! ![]()

Edit: 5-20-16 9:49PM

I pulled the bezel and optics and put a 20ga loop between the pad and negative lead, got a direct amperage measurement.

0.01 Amps

0.18

0.86

3.05

7.57 Amps at 2680 lumens

So each of the XP-G3 S5 3A is getting just under 2A, which is the spec max for these new emitters. This is on the Efest IMR18350 cell, which has been taking a beating lately, lol.

I’ve squared away the switch seat, made a brass cover plate for the top of the switch, so I know every ground point is as solid as I can make it. Pulled the resistors off the lighted tail cap in favor of full functionality of the Bistro driver. All the coulda, shoulda, woulda’s, have been addressed. ![]()

EditII: 5-21-16 11:32PM

A quick beam shot at about 35 yds.

Schoolgirl giggles, silly boy grins. ![]()

And now it’s my EDC, stealing that spot from my Quad Cu X5 that’s been there since Nov 4 ’15, since Dec 22 as a quad.

The belt loop acts as a hook that also catches the hem of shorts, so I can even wear it and deploy the light without having it on my belt. Works pretty sweet, but as with so many things I do, I forgot to double check orientation when I built it… I’ve carried the X5 with the head facing left, on the left side, so when it comes out my thumb is in place over the switch and ready to shine from a tactical grip. This time, I made the sheath with the light facing right, carried left, so it’s opposite and will take some getting used to. Oh well, forgetfulness rears it’s ugly head in so many ways….