Okay we are at the end i guess, So i am fixing this thread up i will remove some things and post all pics from the different dates here so its easier to find. I will keep the stuff about my finger.

My build was meant to be a headlamp but i had to put that on hold because of my finger. I had the idea already in my head but it seemed like a task i couldn’t Handle at this moment.

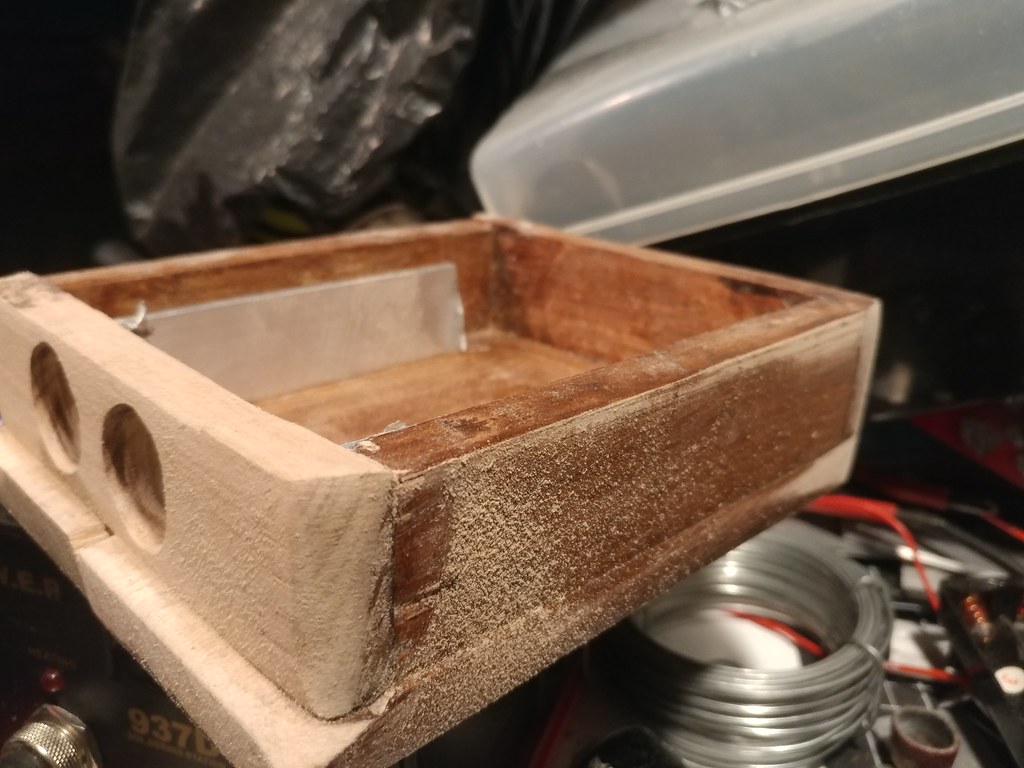

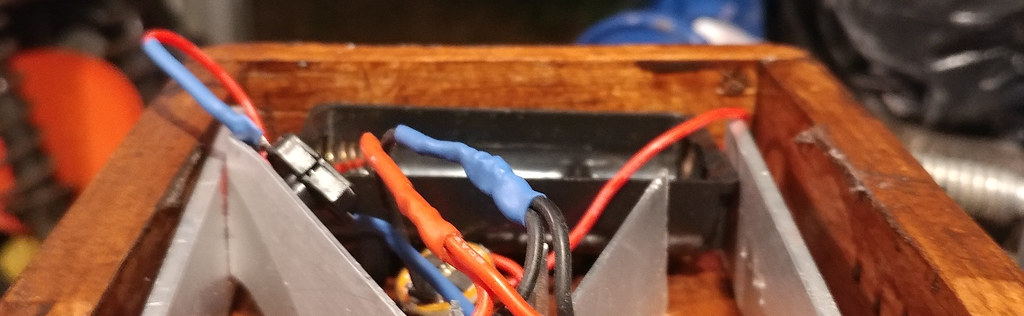

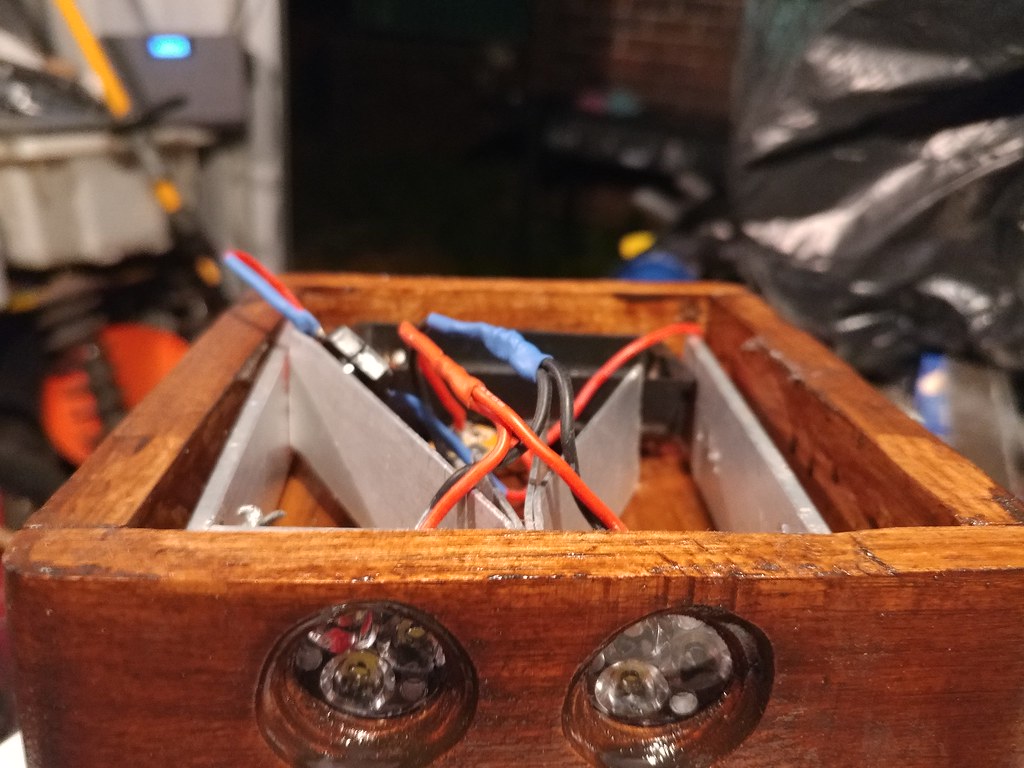

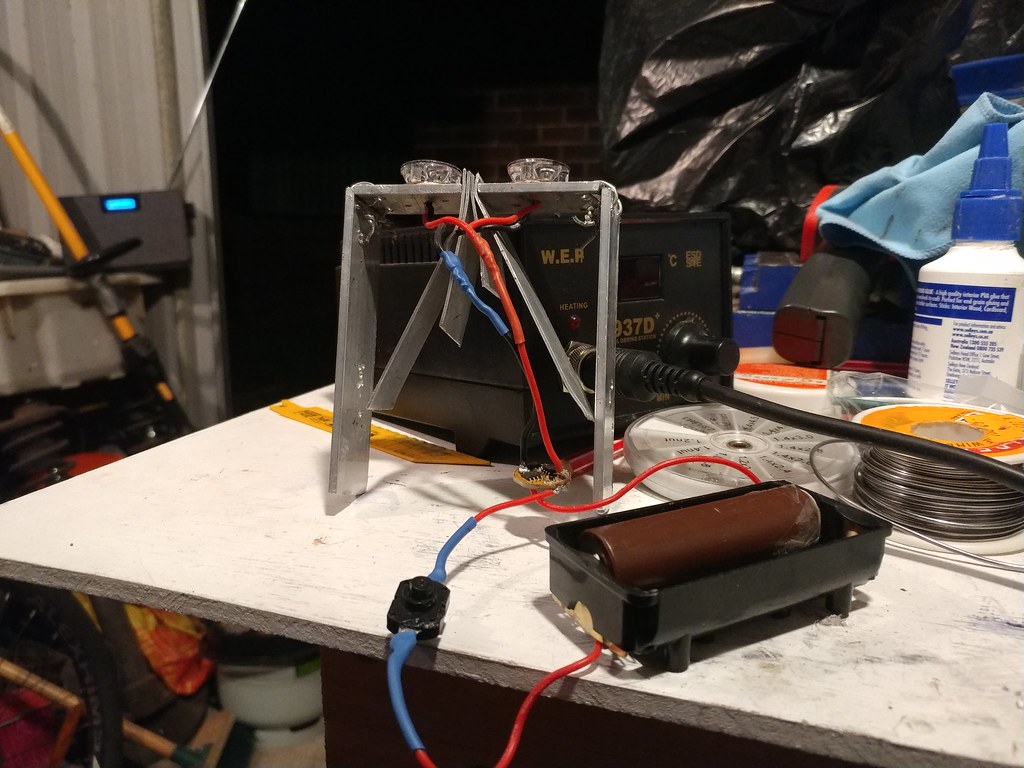

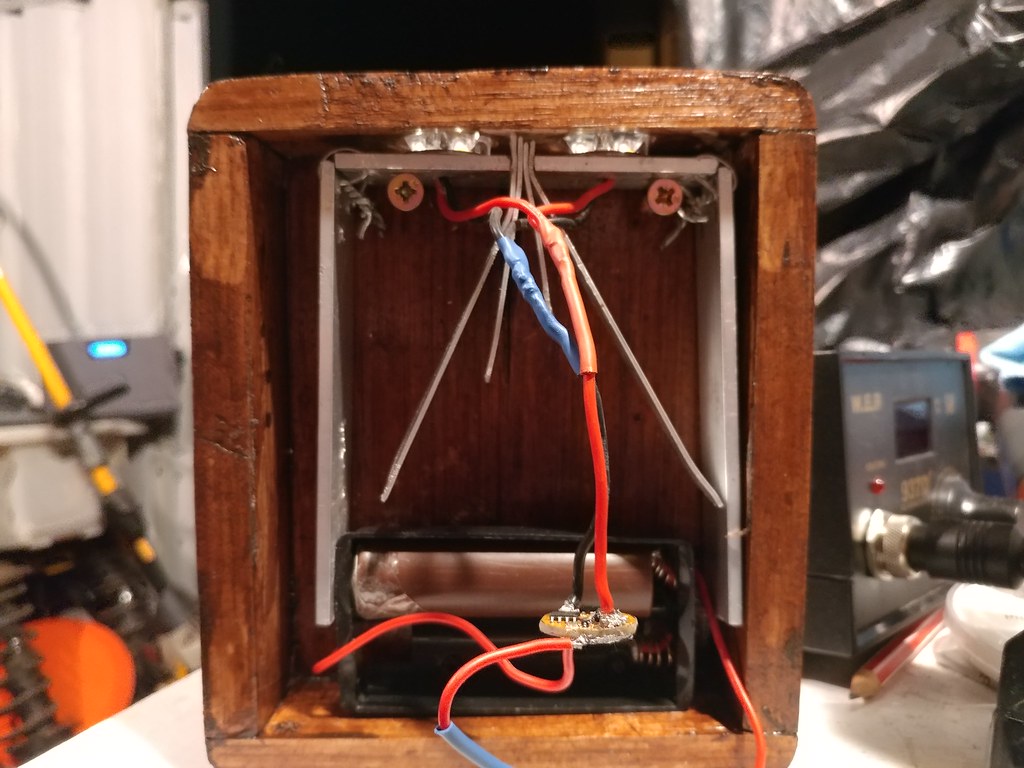

New build is meant to be retro a flashlight/torch of some kind, i am a telecommunication technician by trade and i like all the retro old school items i used to come across at work. Some telephone exchanges still had massive wooden switch boards in place and they where awesome to look at. Old random items like analogue multi-meters with leather cases or wooden boxes and other test equipment gave me the inspiration for this build.

I am posting all the pics in the first thread this thread but i am leaving the writing in each reply please scroll down to see the progression in proper time.

!

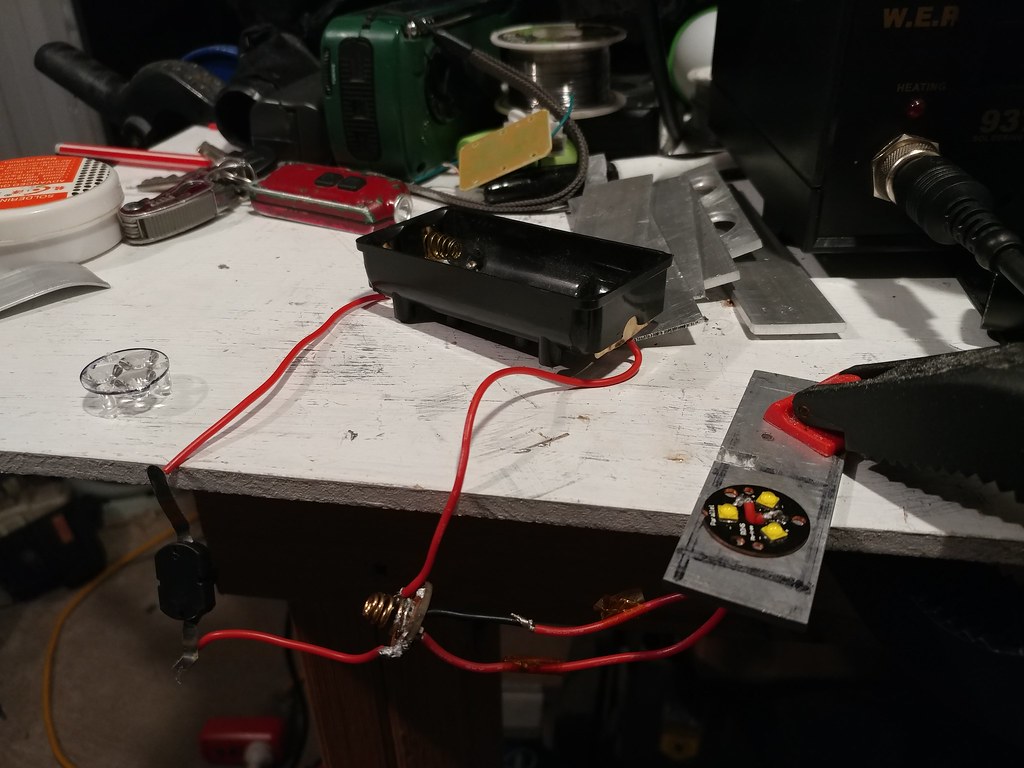

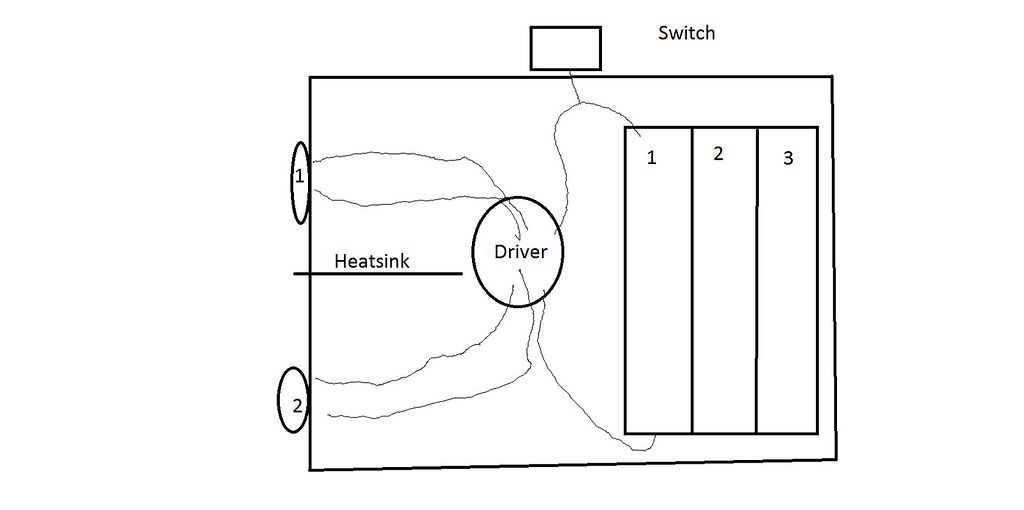

My build items used

- Tasmanian oak

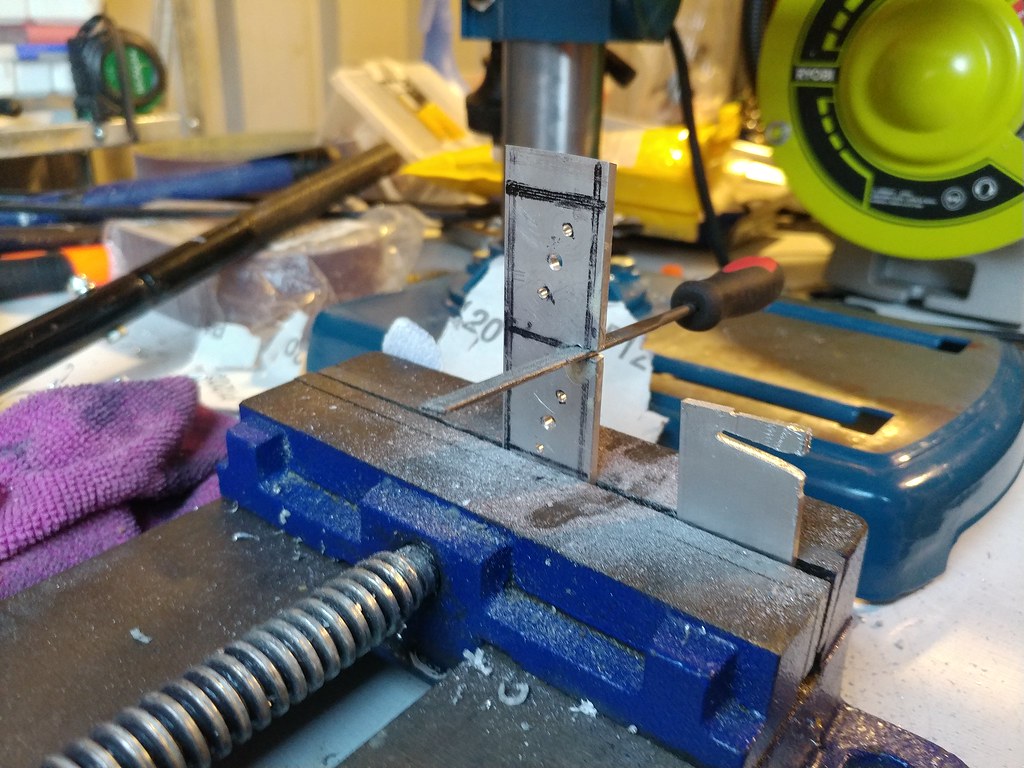

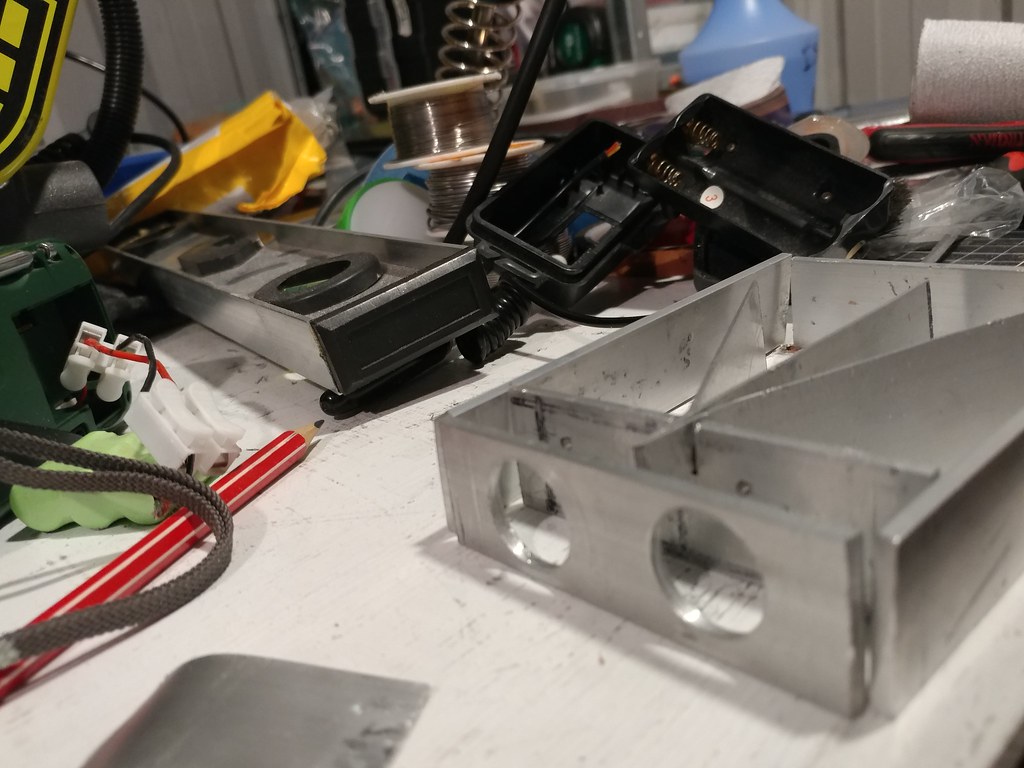

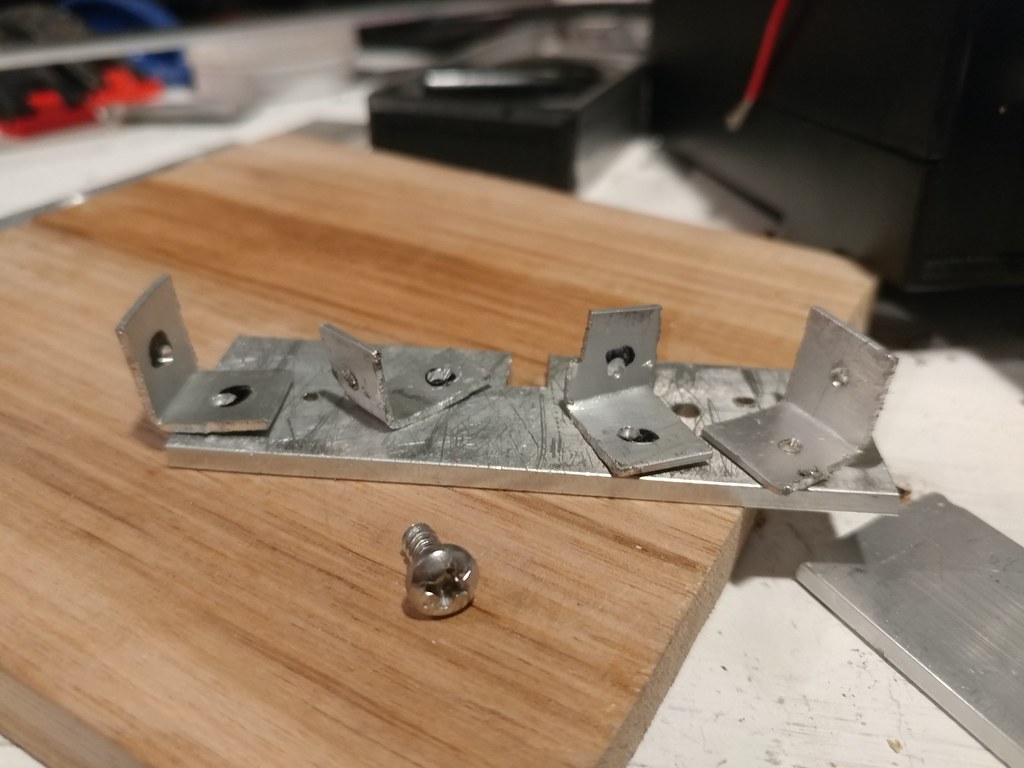

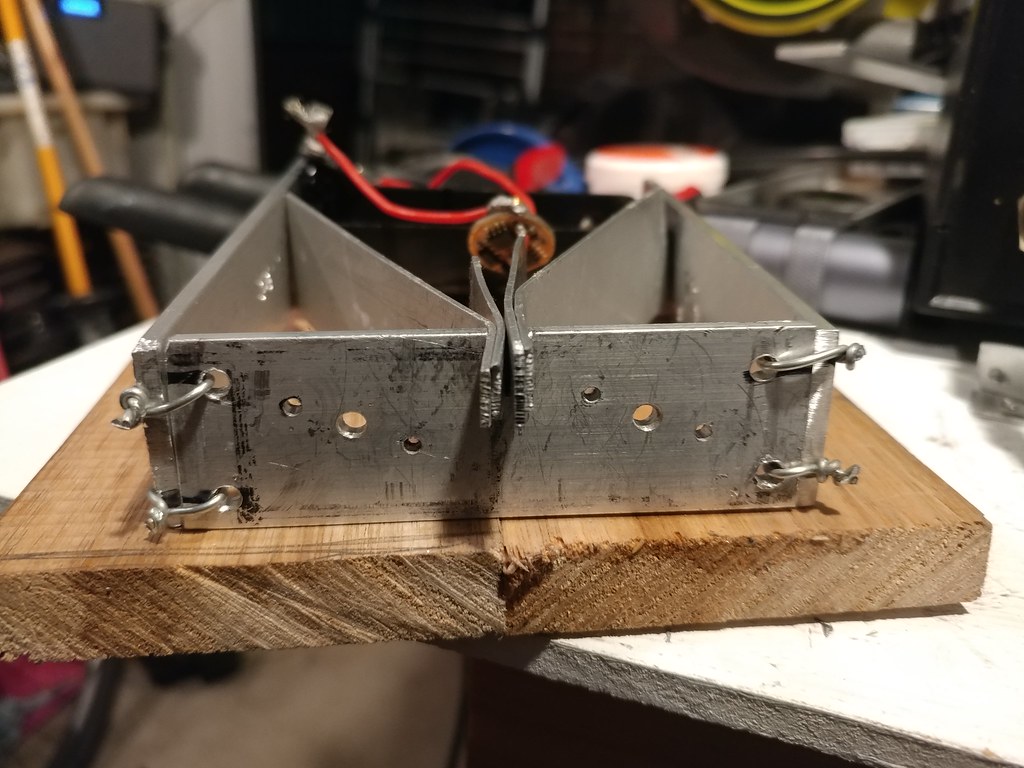

- Aluminum flat bar in various sizes

- Wood glue

- Superglue

- Screws

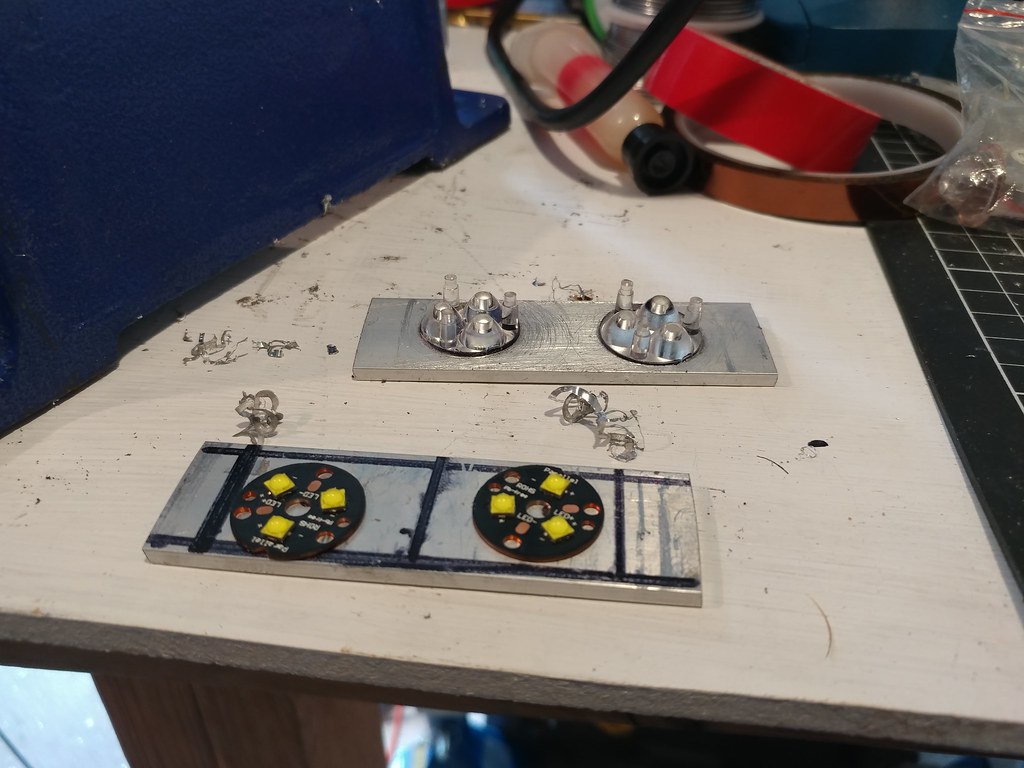

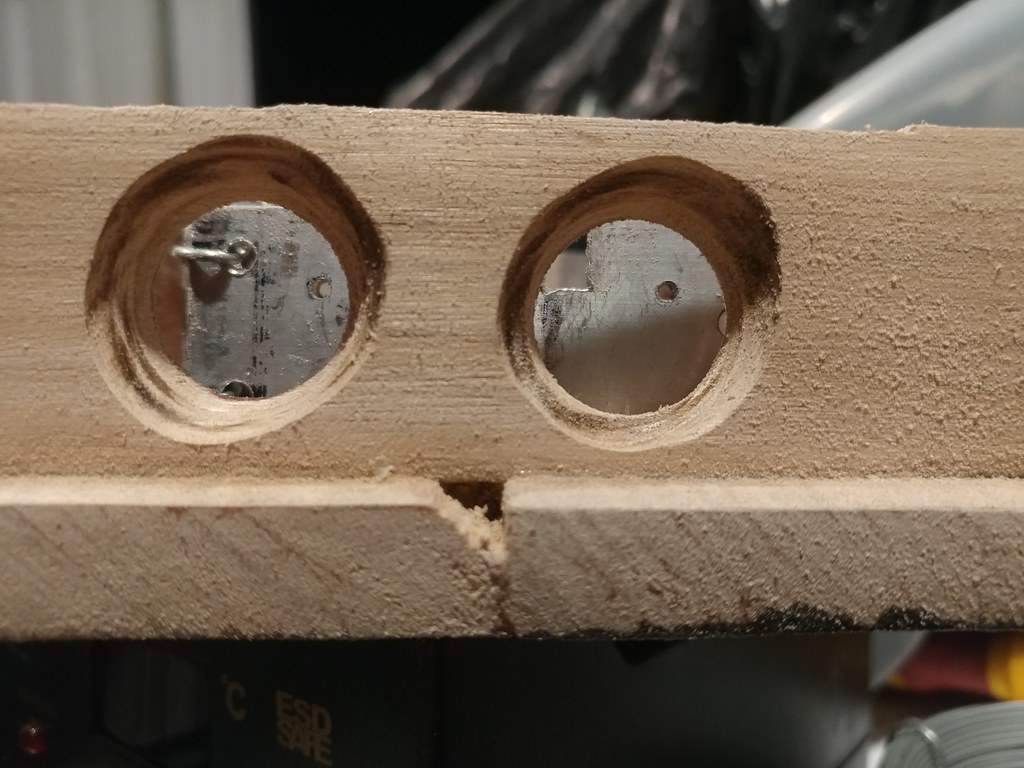

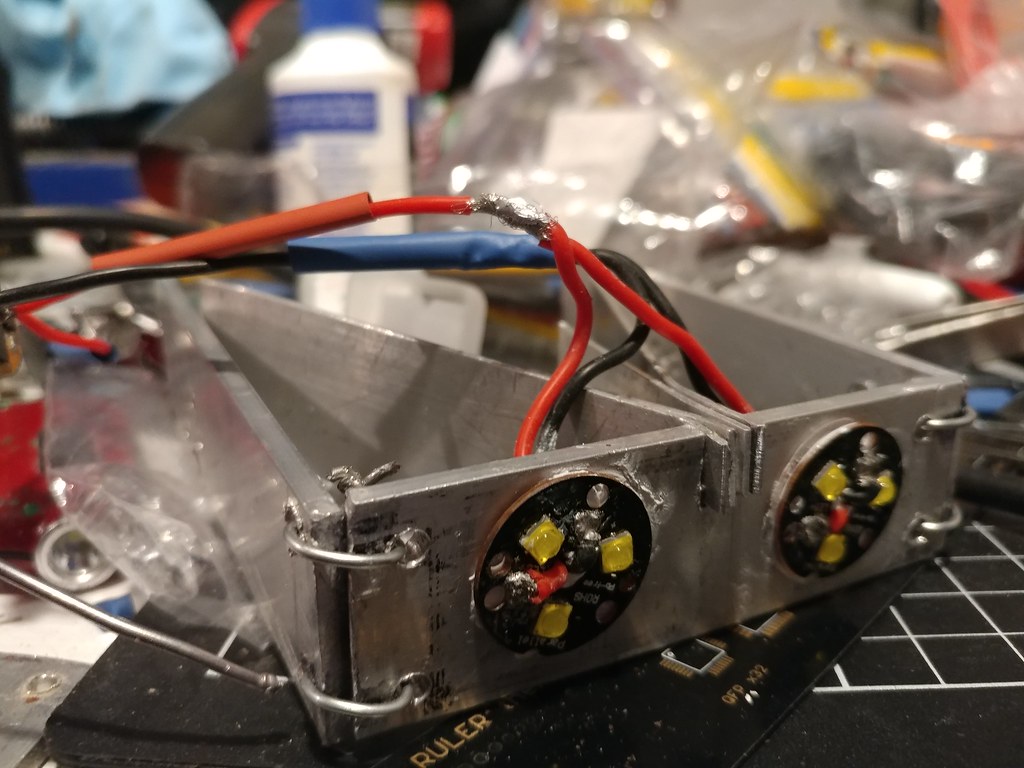

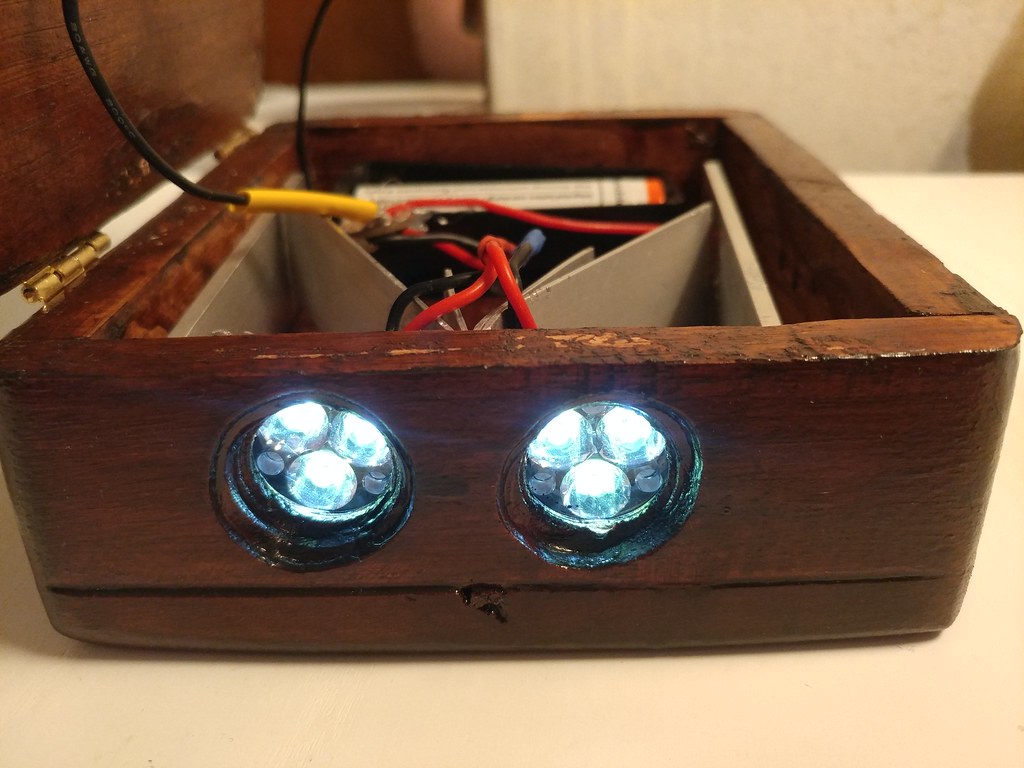

- 2 Triple XPG3 boards in cold white with optics

- BLF A6 driver

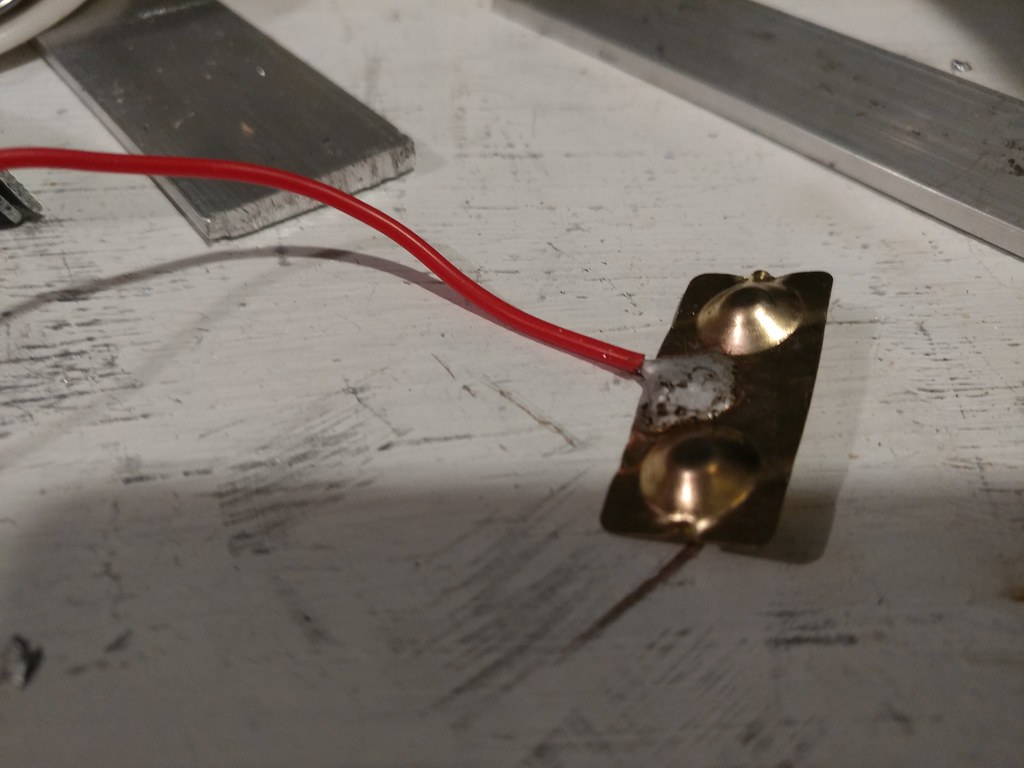

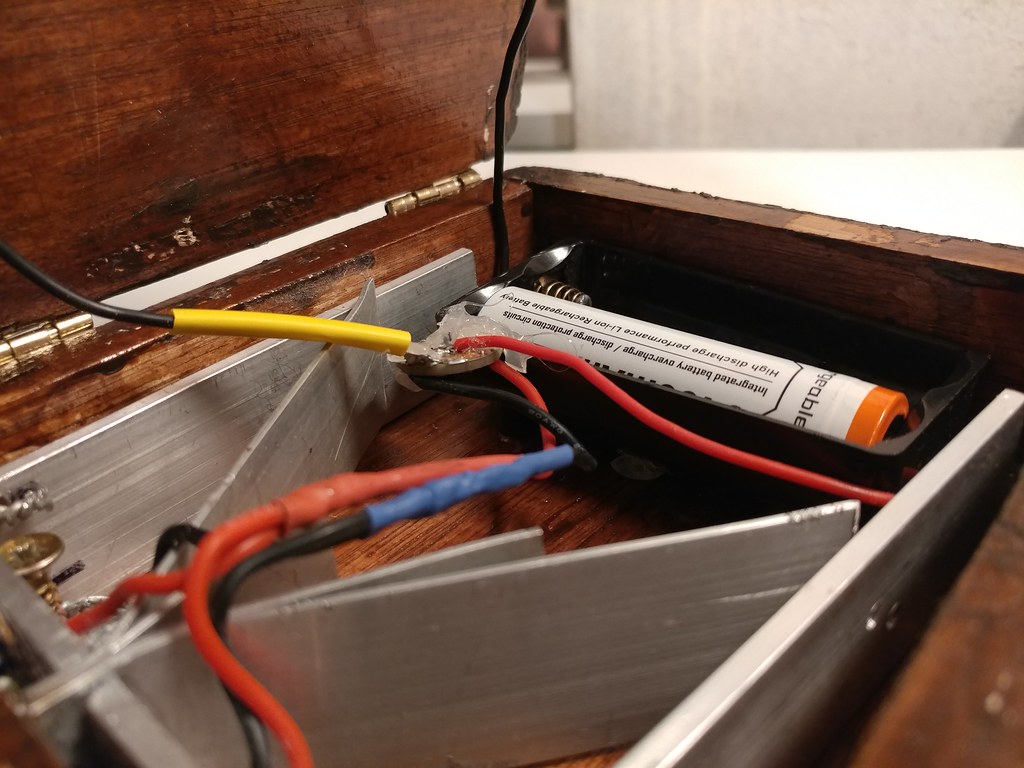

- Dual in parallel 18650 battery holder with brass terminals

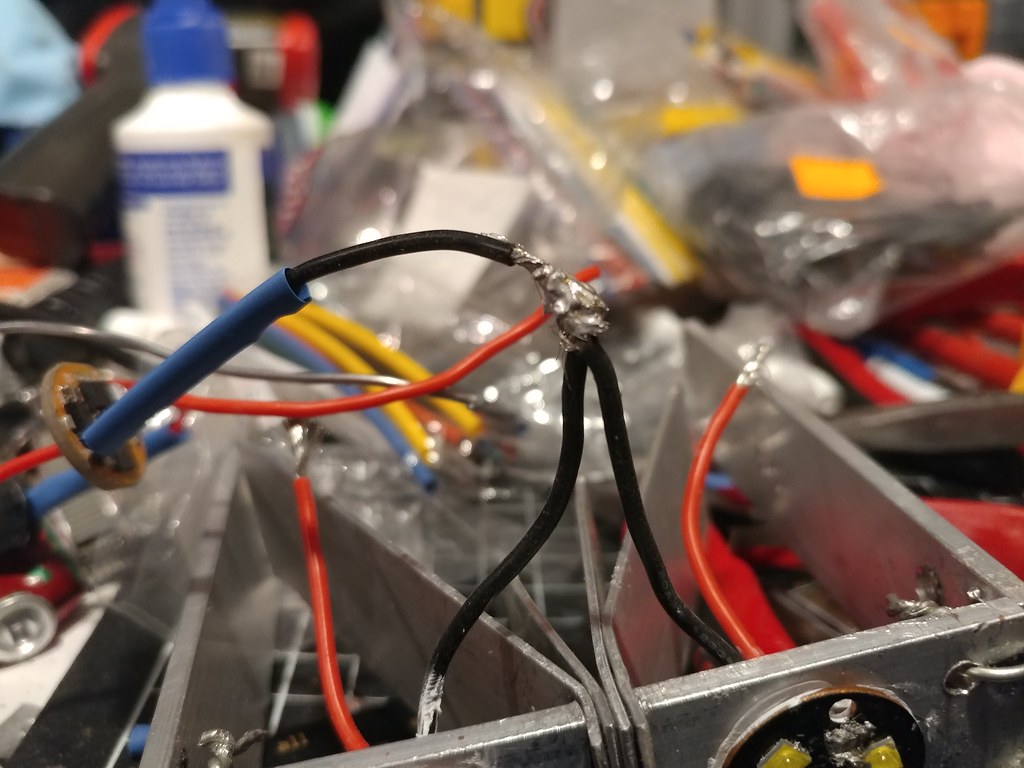

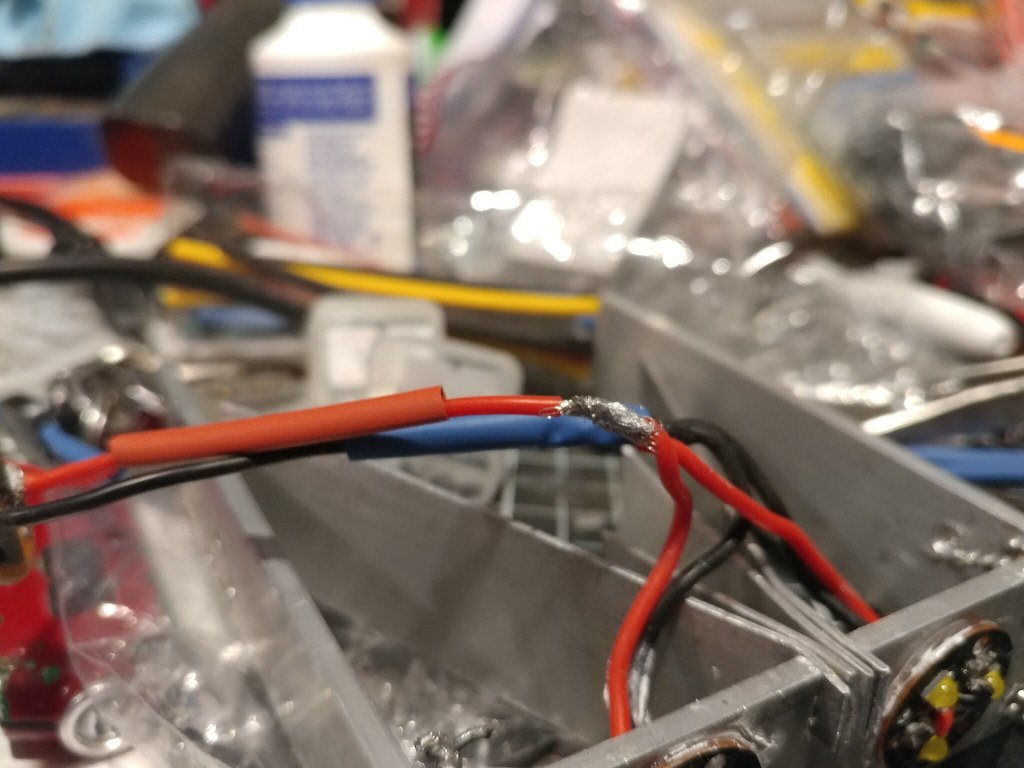

- 20 AWG wire all around

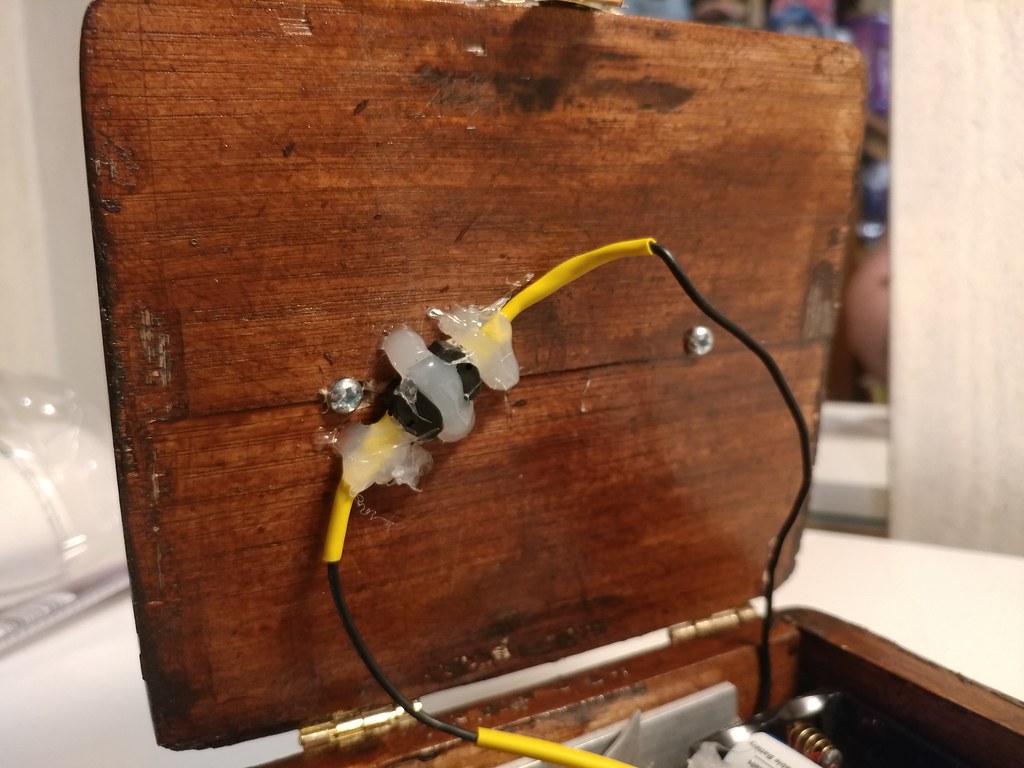

- Clicky switch

- Heat shrink tube

- Brass handle, hinges and lock

- Solder

- Hot glue

- Varnish and stain

Tools used

- Saws

- Drill press + Cordless drill

- Sanders (Bench and hand sanders plus i tried an oscillating sander it was meh)

- Files

- Heat gun

- Soldering iron

- Hot glue gun

- Screw drivers

- Lots and lots of clamps

- Paint brush

- Pry bar ( i glued it together to sander the edges so i had to open it again lol

- Hammer (tapped wood straight)

- Snip and side cutters of various sizes and stuff

- Tweezers for soldering

!

I was meant to start the build this weekend cause my girlfriend is in Western Australia for a few days but last night i made a booboo lol. I sliced of part of my finger so i can’t lift much today probably for a few days. I just hung out the washing and its sore and bleeding a tad.

I lost enough blood to make me laugh at every thing fairly cheap high hahaha.

!

!

I was trying to walk it of but it wouldn’t stop bleeding.

!

!

Build thread starts here it can also be found in the comments on various days

Day 1

!

!

!

!

!

Day 2

!

!

!

!

!

!

!

!

Night 2

!

!

!

Day 3

!

!

!

!

!

Early morning day 4

!

!

!

Late night day 4

!

Day 5

!

!

!

!

!

!

Day 6

!

!

!

!

One whole day of sanding lol

!

!

!

!

!

!

Day 7

!

!

!

!

!

!

!

!

!

!

!

!

Day 8

!

!

!

!

!

!

!

!

Finally!

This is the very end product i varnished a few odd areas and the switch to make it all pretty. I also extended the negative cable to the switch cause it was a tad short

!

!

!

!

!

!

!

!

!

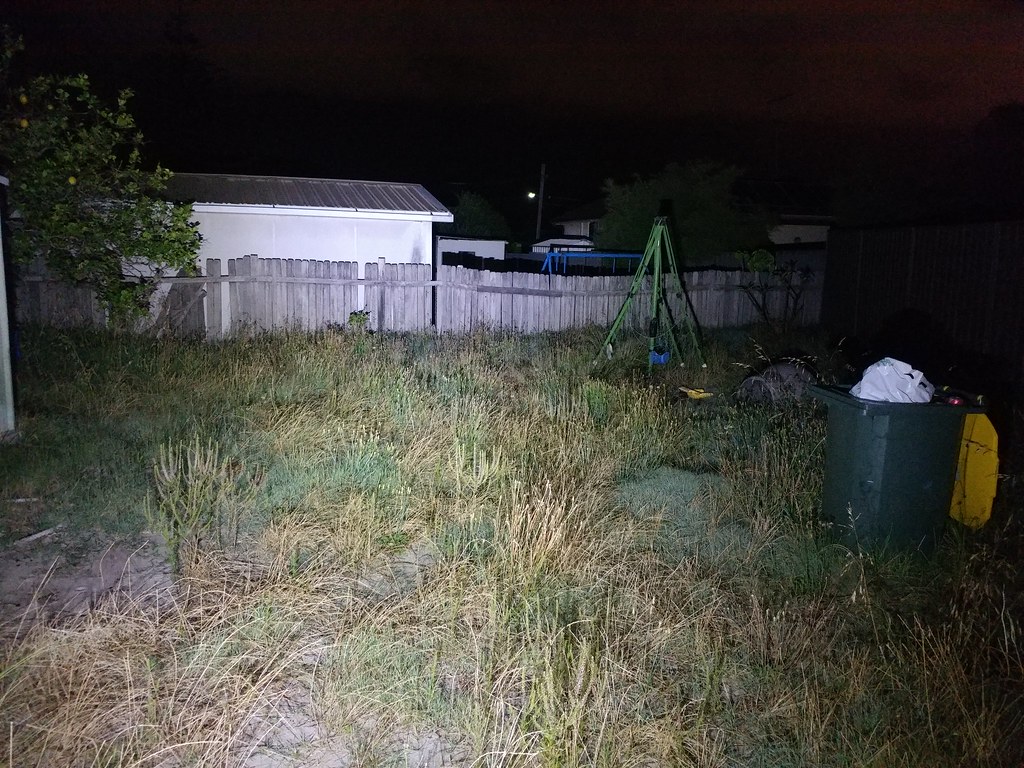

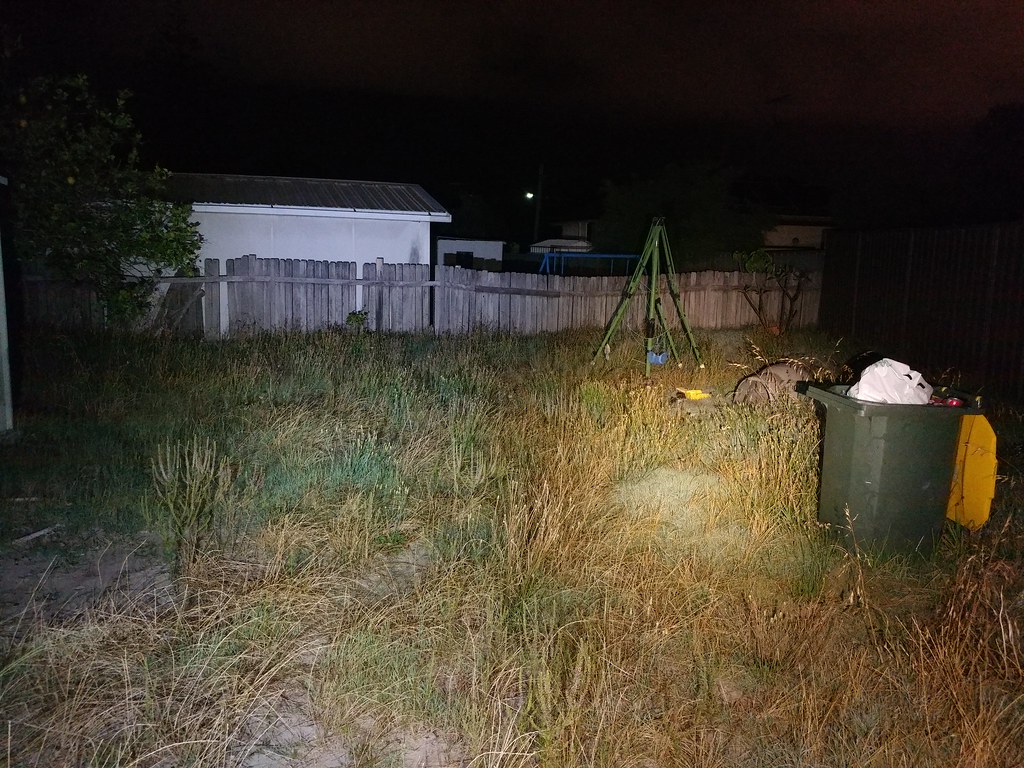

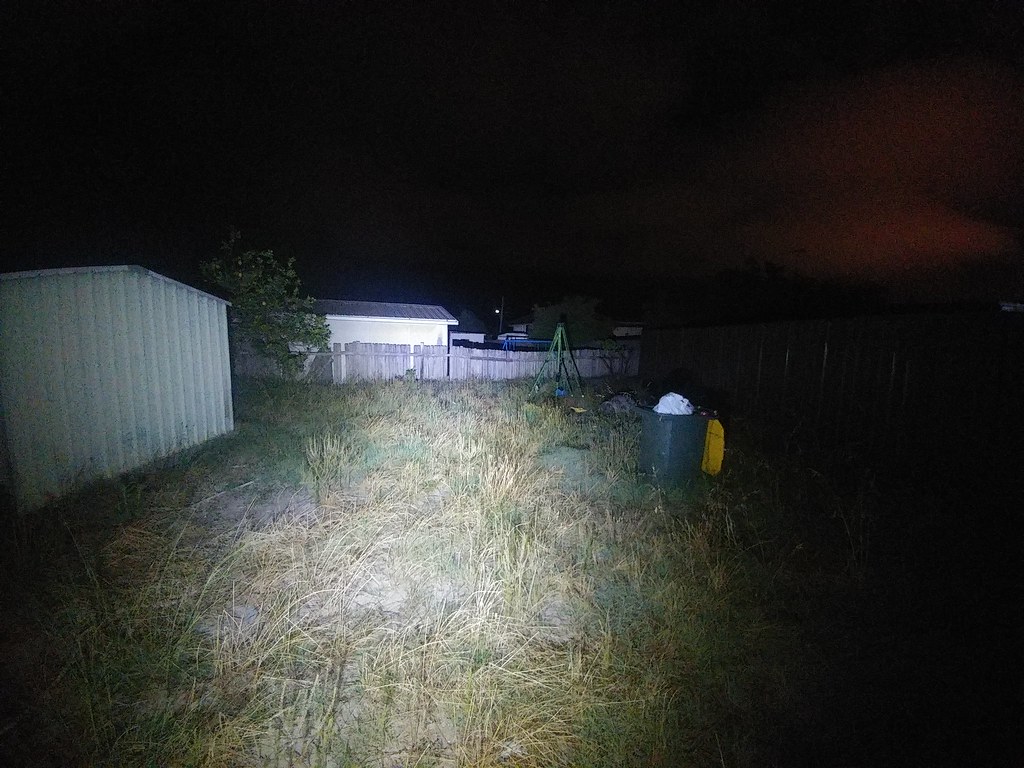

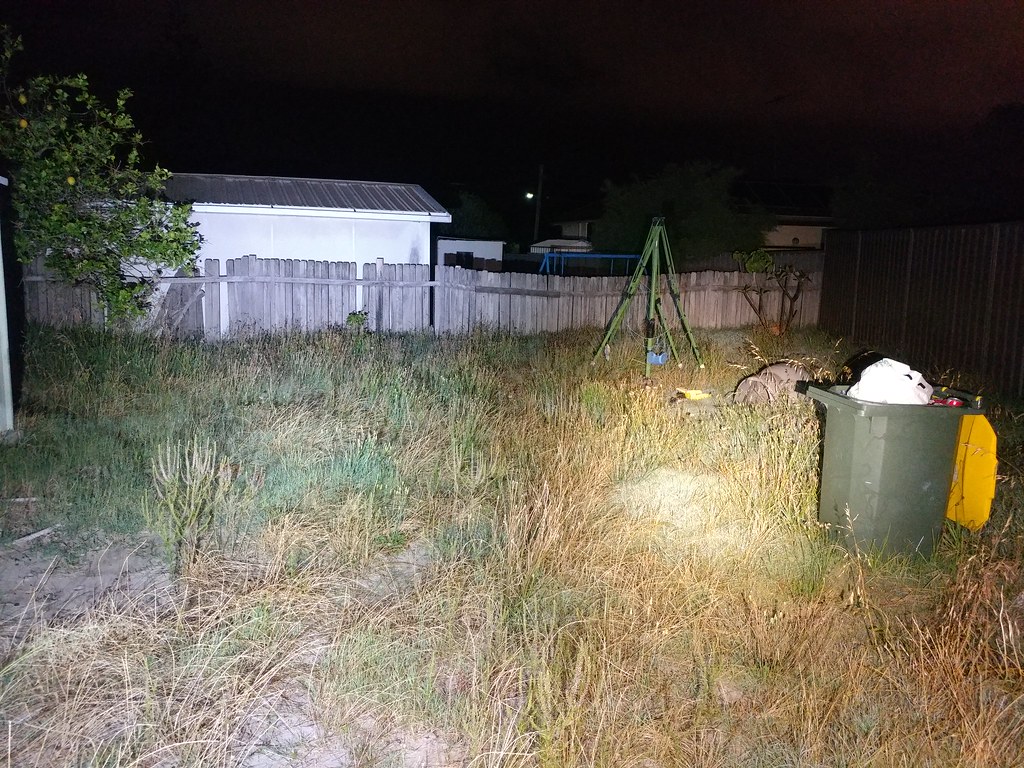

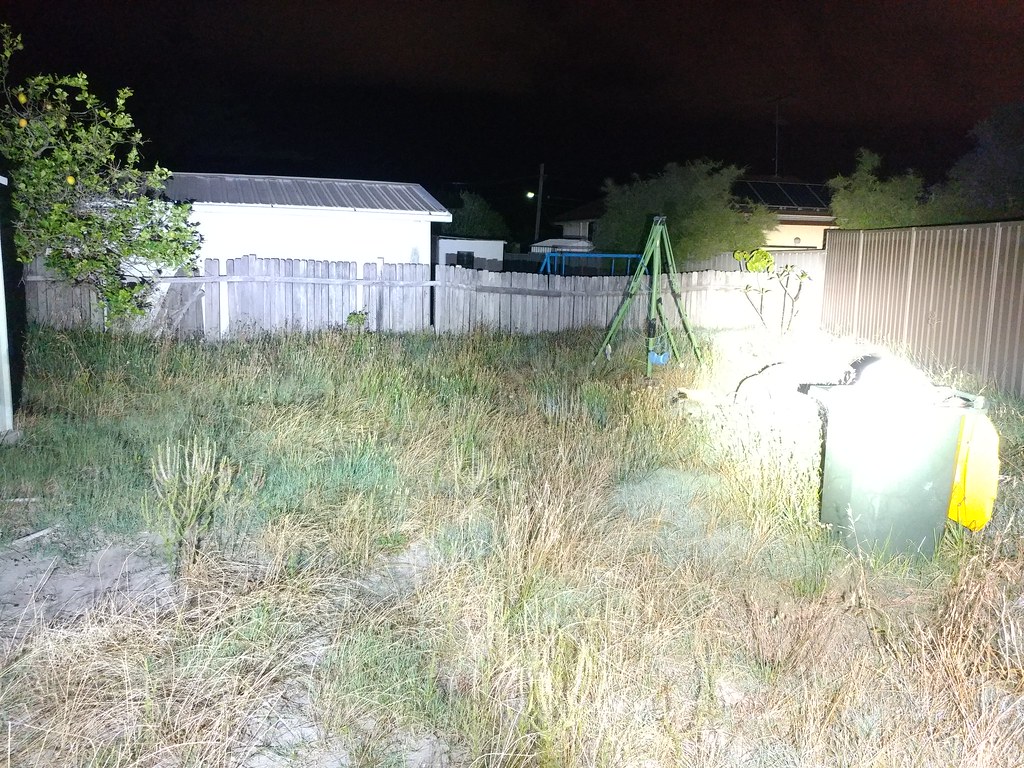

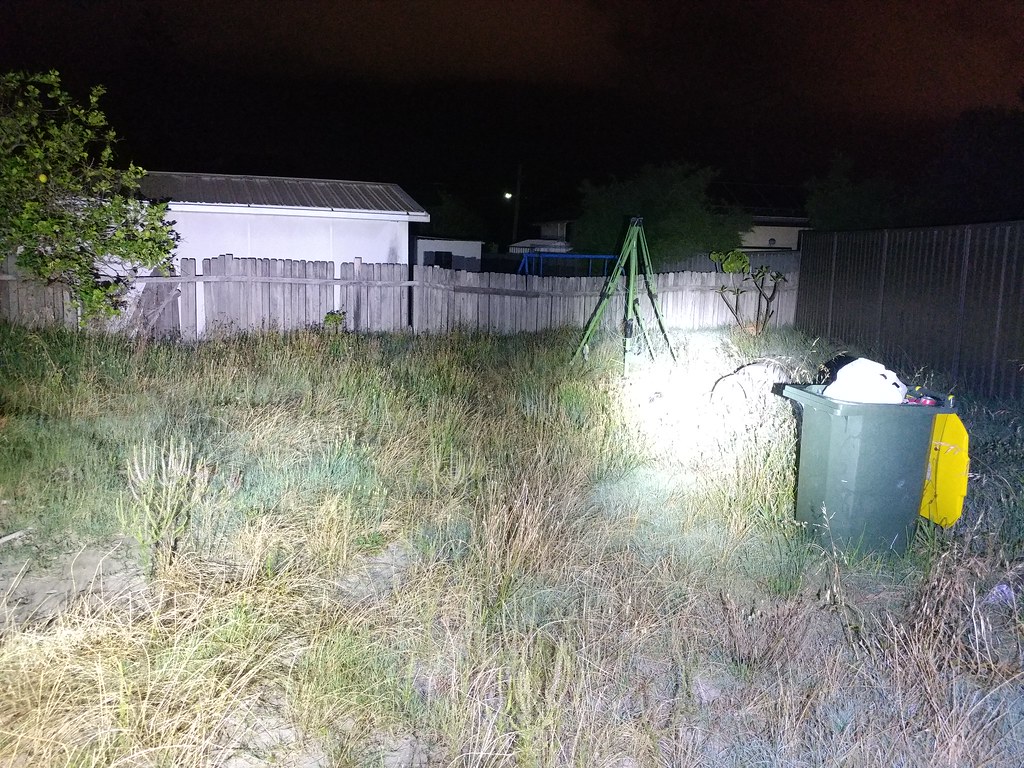

Beam shots

The light is using the BLF A6 driver. Seeing as the light has 6 LEDs its super efficient and bright in the lower modes. All these pics are taken at ISO800

!

!

!

!

Usually the yard doesnt look that big but its the camera playing trick with the wide angle you can see the length to the fence

!

!

Just for comparison we have my comp build to the left and an actual BLF A6 to the right you will see the tint difference

!

!

Mode 6 the difference here is clearer then the rest of the pics

!

!

Both lights in direct drive you can see the A6 is washed out by the build but you would expect that.

!

!

Way to much light for the yard the Convoy L6 is on the right and my build on the left. Plus you have a hot spot vs pure flood

!

!

Very last pic for now Eagle Eye X6 with a SST40 Direct drive to the right and my build to the left. Interesting note is the difference in tints between the two both cold white.

!

!