https://www.ebay.com/itm/322442798670

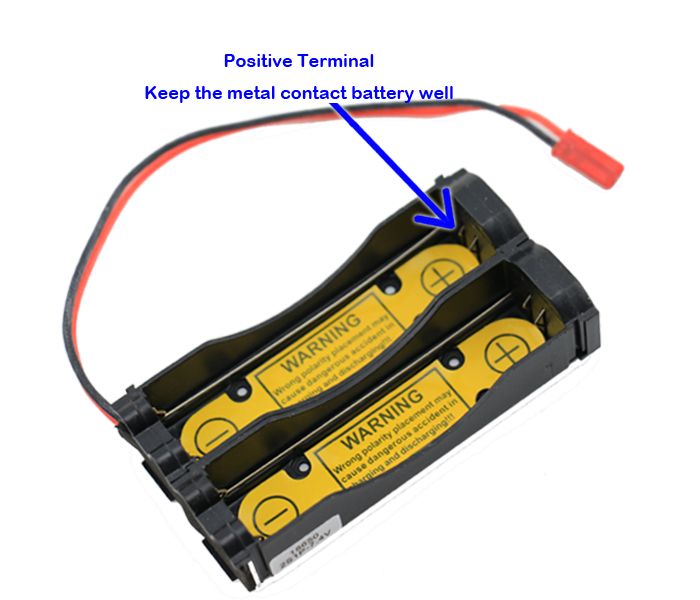

Has anyone used this 18650 holder (or one similar) that has a built-in protection circuit to make a protected battery pack?

https://www.ebay.com/itm/322442798670

Has anyone used this 18650 holder (or one similar) that has a built-in protection circuit to make a protected battery pack?

Mmmnope.

Small, thin contacts of unknown spring load tension. Thin input/output wires. You're going low power, doesn't it? If not, look elsewhere.

Yes, we know. No UltraCrook batteries. ![]()

@Barkuti

Thanks for those observations. I am looking to run two of these in series to make a battery pack for a Roomba. The unit is a REALLY old model that has a 14.4V NiMH battery pack (that no longer works). I would remove the li-ion cells and charge them in my XTAR VC4 in case you are wondering.

Small battery packs are built pre-assembled, with BMS:

I am pretty sure you could get a no fuss, nice quality Ni-MH replacement battery pack for it. I doubt you will get any improvement with li-ion in practice, and much less if done that way. Whether soldered/welded cells or not, contact resistances add some resistance burden to the current flow in the battery pack whose hindering is proportional to the square of the discharge rate. However, when not soldered or welded the contact resistances are significant, i.e. if a cell in the pack has 30 mΩ of internal resistance and its contacts add ≈10 - 15 mΩ, that's noticeable. I do not mean to say it cannot work, it can but I don't see the point. Personally, I would probably buy a replacement Ni-MH battery pack or go with a li-ion conversion, if only because I have expertise in soldering cells and battery pack assembly.

If you don't want to mess with battery pack assembly, this 4S1-4P 18650 DIY battery holder with optional BMS looks pretty neat:

It's a really neat kit with many different parts, yet can't help but think it's rather expensive.

those packs are limited to 5A, rumba may pull more, especially during start up. i’d check that first, i would go with oem pack, so you can still use oem charging cradle

Thanks for all the feedback. I don’t trust the quality/ratings on those pre-made packs aliexpress so that’s why I wasn’t considering them. That DIY holder you found looks much better then the one I linked from eBay! You made some good points about my idea of switching to li-ion for my old Roombas; I am now thinking I should spend my efforts finding some good OEM-sized replacements. I originally wanted to make my Roombas run of my plethora of 18V Ryobi li-ion batteries, but their size and form factory just create too many issues with the Roomba. So then I continued down the li-ion path thinking full DIY, but perhaps that doesn’t make sense assuming I can find a quality NiMH replacement battery for my vacuums. I do solder so perhaps I will have to resort to making a quality NiMH pack (that fits inside the OEM shell) myself. I hear you can solder li-ion too, but since they can explode or catch fire I was shying away from that. ![]()

Particularly I myself do solder li-ion cells. Using a combination of steel flux and low temperature solder, a Bi50Pb32Sn18 Rose metal variant (tap/click here to see where I get it, zhuykoff merchant @ ebay), soldering cells is a breeze.

The Roomba Ni-MH pack is a 12S sub-C one, doesn't it?

Left picture is a big bag of Bi50Pb32Sn18 pellets. Right picture is a Dewalt De9502 battery pack rebuild I did more than two years ago. I switched to a multiple strand solder wick approach since then. The fellow I gave the battery pack to broke it soon afterwards, he left the pack discharged a few days and it died because at least one of the cells got reversed. When a Ni-MH cell is left to rest polarity reversed, it rests forever (dies). Along with a new pack I built with Turnigy sub-C 5000 (cough!) mAh cells, I rebuild that pack sometime later, swapping a dead cell and another one whose internal resistance was a tiny bit above that of the rest:

Since I found no shrink wrap for sub-C cells, I used wrap meant for 26650 cells, that is the reason their newer blue wraps look overly big for them. That is a balancing connector, btw; not really necessary with Ni-MH, though, as a long, gentle trickle charge does it.

Turnigy sub-C 5000 mAh cells can be purchased at HobbyKing.com. Slightly overrated, but as far as I know they're the highest performing sub-C cells in the market.

Yes, I am fairly certain my Roomba’s batteries used sub-C cells.

If you only factor in the cost of the cells, it seems I can get a lot more for my money with li-ion cells rather than with NiMH cells. That 5000mAh sub-C is 1.86Wh/$ (and that assuming it isn’t overrated but we know it is) whereas these li-ion cells are 4.84 Wh/$. So if it comes down to having to build a new battery pack, I might have to try li-ion after all. That said, I still hope to find a quality NiMH replacement OEM-styled (Roomba) battery for a decent price.

Ive used those style of battery holders before, they are somewhat picky about batteries making a connection on the negative side, so you might have to trim the plastic wrap on the negative terminal.

bcm00re, energy density isn't all that matters. Your Roomba was designed with Ni-MH sub-C cells in mind, a battery chemistry whose discharge curve is very flat:

/Turnigy%20Sub-C%205000mAh%20(Gray)-Capacity.png)

Looking at these discharge curves, it can be clearly discerned that, even at a high drain rate, the voltage in the cells stays pretty high (above 1.2 V at 5 or 10 A rates for ≈75% of the capacity or discharge time) This is unlikely to happen with most li-ion cells nowadays, whose chemistry and discharge curves are tuned to descend progressively. Changing the device's cell chemistry may affect its ability to gauge runtime or remaining energy in its cell pack.

It still should work well, though. You need to know what is the cut-off voltage of the Roomba, in order to properly determine the effective useable capacity and energy with li-ion cells.

You need good, clean contacts in both holders and cells, and sufficient pressure for it to work. Then you will use a external battery charger to refill the cells. Honestly, I believe you are better soldering the cells, assembling a custom battery pack with battery management system, and probably using some external battery charger to fill the pack.

The Roomba may still try to charge its battery pack as usual, this means at some point it will pump up the voltage of the li-ion pack to something higher than recommended. The BMS should kick at that point (≈4.3 V per battery stage, where a stage is one or more cells in parallel), just bear in mind it will reduce the lifespan of the cells if you allow the Roomba to rest with a fully charged pack that way as a rule.