The HK90 is a rather unique light, triple SBT90.2's in a 100 mm diameter head, with triple 21700's in parallel. I recently got one in from Neal's store in sand color. This is about the closest thing to an old classic, the BTU Shocker, but updated. Of course I couldn't leave it in one piece for long, as I did with the Shocker with modding, so here's some of the details.

Had to give the 40T's a solder blob job for better contact:

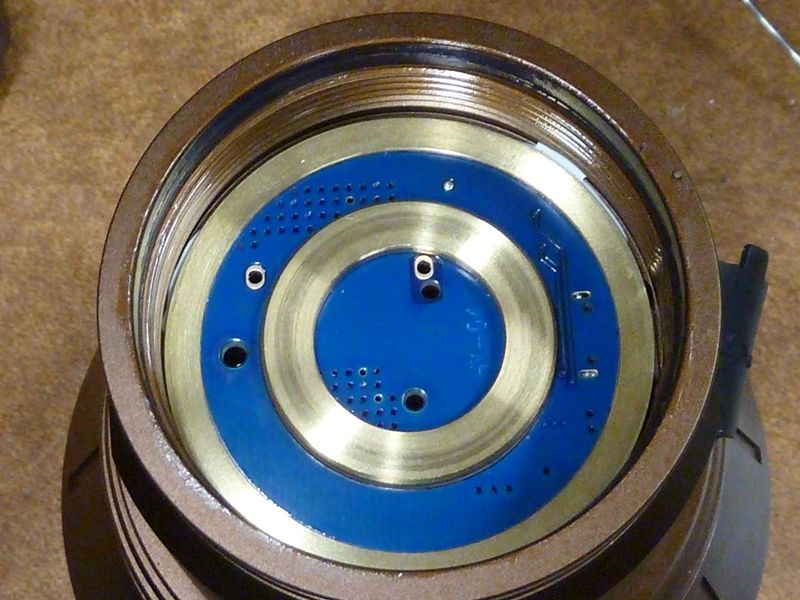

Fortunately, they provided a large hole in the driver (on the left) that could be used for leverage to pry out the driver, breaking the glue seal. The glue is a soft silicone type of sealant, so not so hard to break:

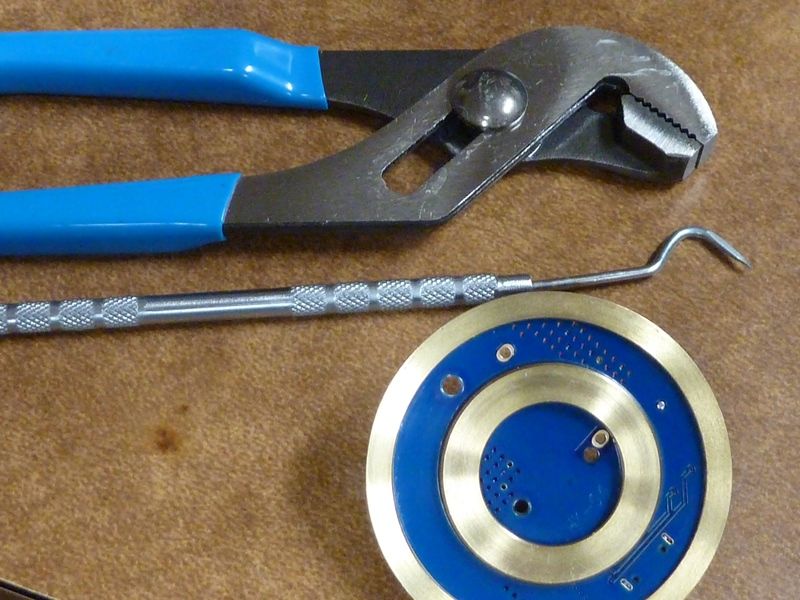

These are the tools I used to pop out the driver. The bent end of the pry tool fit in the hole, then I used the plyers as a lever on the pry tool. Just had to add hard plastic on the edge of the head so not to damage it.

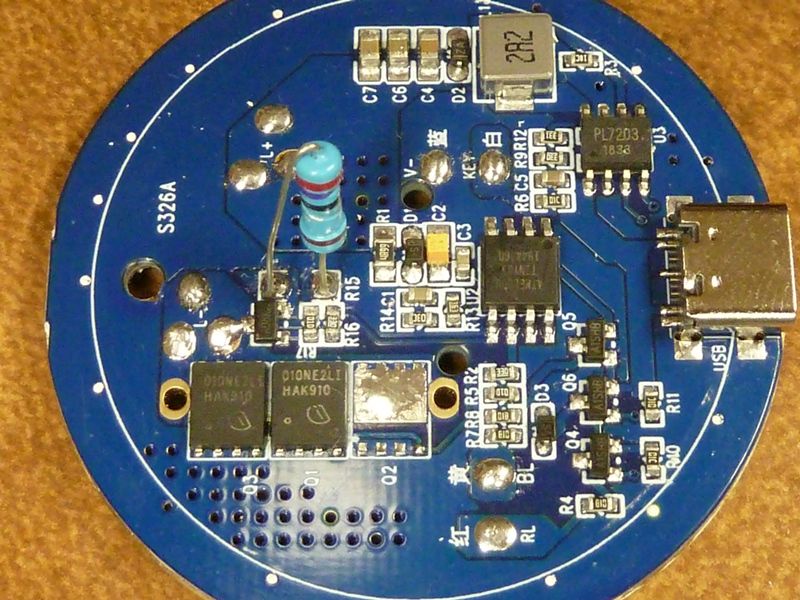

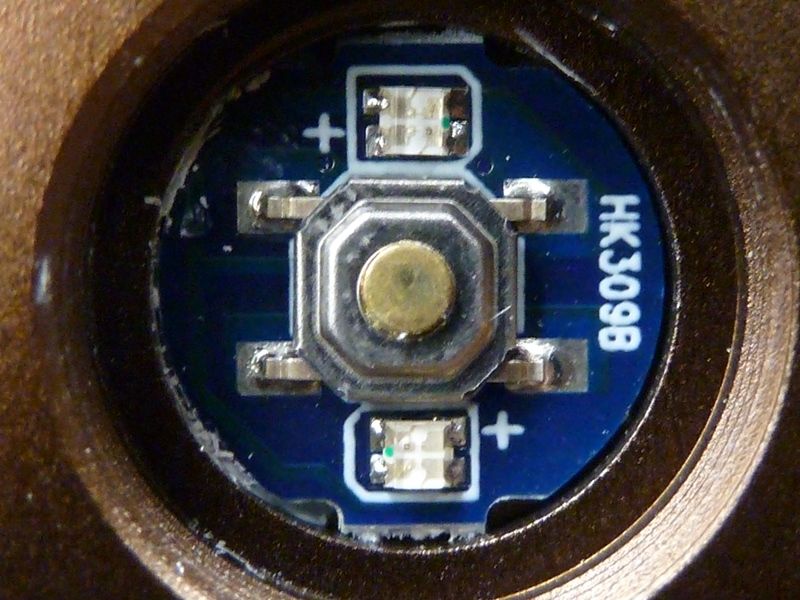

The driver is the same design as the HK04 - matches in every detail except the size:

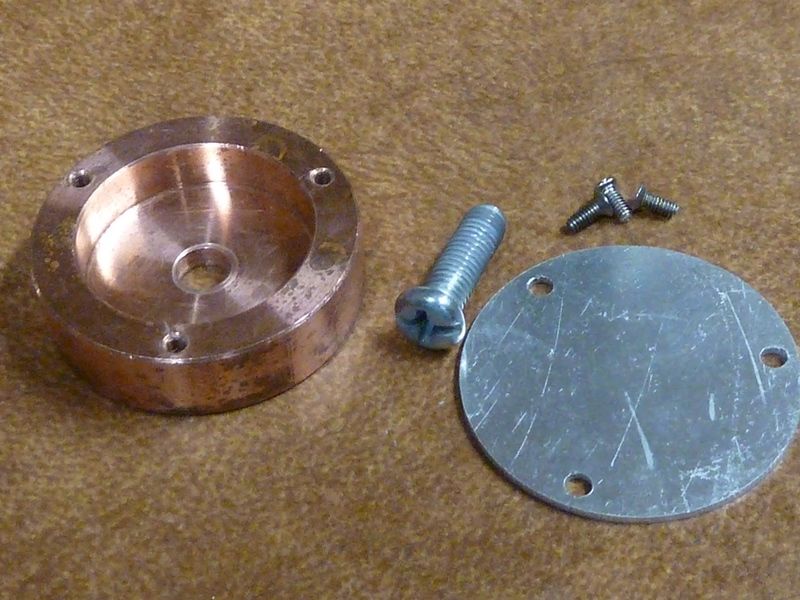

Under the driver is where it gets weird. Normally with a reflector like this, there is one center large screw, but in this light, there is a screwed down aluminum plate:

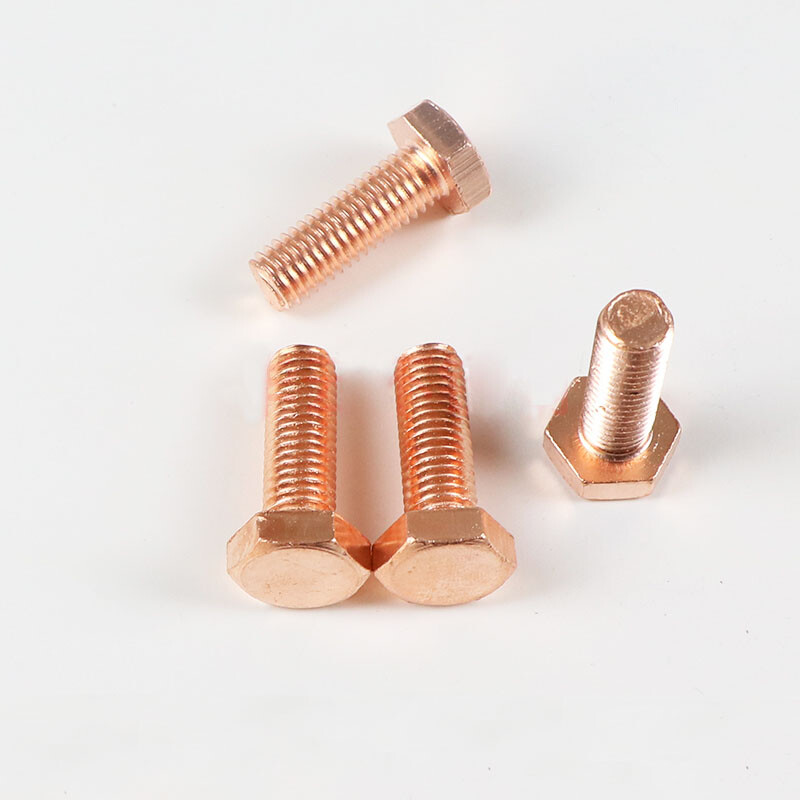

Removing the plate, found this. Wut? It's a copper plug 1/2 filled with thermal grease, covering the screw head:

After cleaning it out:

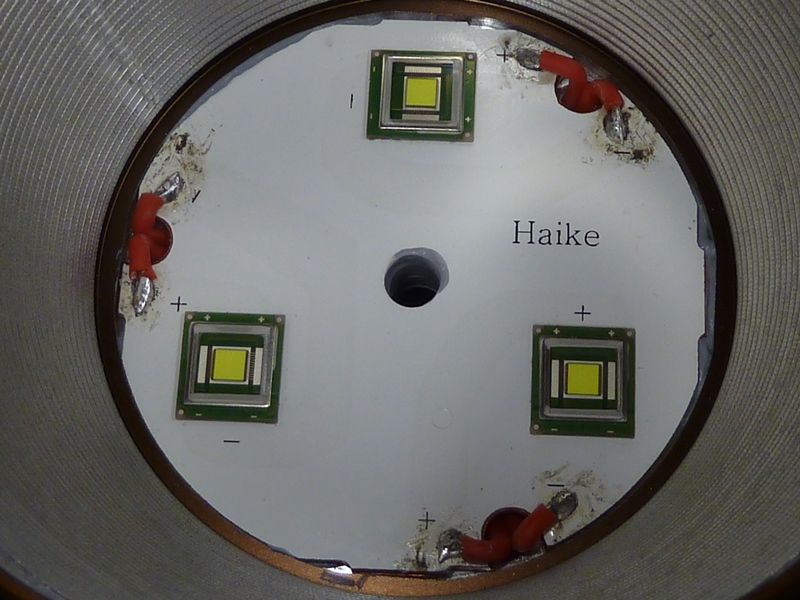

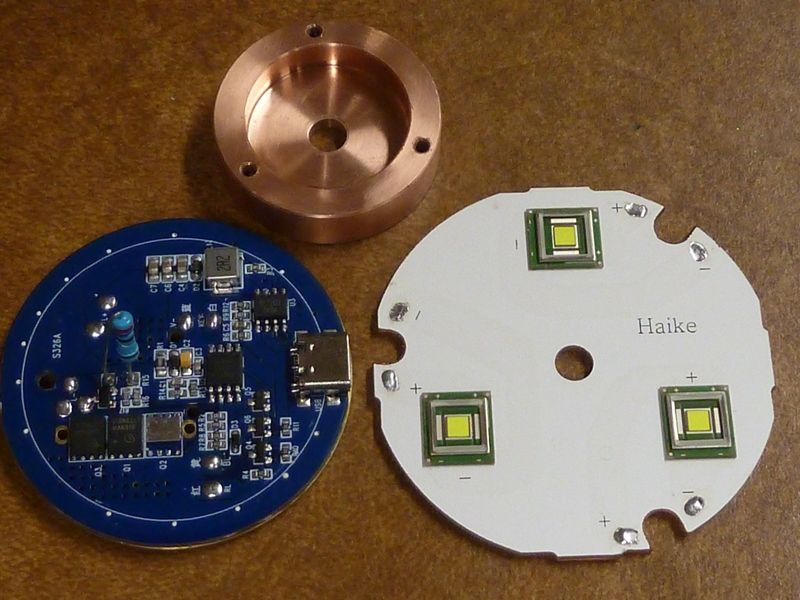

So here's the pieces:

After polishing with a fine GRIT pad:

The Shocker reflector, ok, they modded it slightly to remove some weight, which is what I used to do on modding Shockers. They even made cutouts to clear the solder connections (I did that as well). They really still could have done more to reduce the weight, but maybe that would have been even more expense.

One large MCPCB, 20 AWG wires. Another weird thing - guess they ran out of black wire:

View of the shelf - light covering of thermal grease but well spread out (how it should be), and shelf is pretty thick, at least 4 mm:

Large MCPCB and 2.0 mm thick:

The copper plug is 35 mm wide by 9 mm thick. At the center base it's 3.1 mm thick and the outer wall is 5 mm thick:

The weight of some of these components:

The switch LED - these are dual color LED's, red and blue. The red and blue are controlled by the USB charging circuit, while Anduril controls only the blue LED's. This switch PCB is glued down, haven't tried removing it yet - I broke the HK40's switch PCB attempting to do so, so might leave as-is.

Couple of issue as well. The holes have not been deburred on the bottom of the MCPCB and there's a contaminant on the right side shown, might be solder:

Why are these wires so stiff? Turnigy and other wire we source from Hank-IOS or MtnE is much more flexible:

It is 20 AWG:

Here's a look into the driver cavity where the copper plug snugly fits in. It's a tight fit, but as you can see, there's no anodizing on the contact surfaces, they did the right thing here. The machining marks are almost cosmetic - I can't feel them at all. Looks like they polished the surfaces but didn't take it down enough to remove the marks - sanding should get rid of them easily. The aluminum shelf is 4.7 mm thick at it's minimum in the center, and 9.4 mm thick in the outer part. The LED's are probably 80% sitting over the thick 9.4 mm part. Since the thinner center section is supplemented by the copper plug, it's total thickness is about 7.8 mm at the center.

The center screw is an M5 x 16mm.

In the head, all the anodizing is stripped and the inside has ridges, dunno if intentional. Again, machining marks on the shelf but can't feel them, so the must not be significant. Sanding should smooth them out easily. If you notice, the anodized ring isn't exactly round, it has 4 flat spots which match up to the 4 flat spots on the MCPCB - interesting they made the fit tight and locks it in to position so no need for screws to prevent rotating.

Glamour shot of major components all cleaned up, showing relative sizes:

So I'm not quite sure what the purpose of the thermal grease is. There is no grease at all where the copper plug makes contact to the aluminum housing. Seems like applying a lot less to the outside of the plug instead of the inside would have had more thermal value? With the copper plug, I would think they were trying to keep the driver cooler and pull more heat from the LED's. Copper stores heat better than aluminum which can be a pro and con, but adding copper under the LED shelf is what many of us modders have been doing for years.

Overall, it's all what the Shocker was at the time - outstanding combination of lumens and throw with a big hot spot, and built like a tank, but with improvements:

- SBT90.2 LED's - expensive but best combo of lumens and throw

- side e-switch with driver running Anduril (wish it was firmware updateable from the outside though) with dual high performance Infineon FET's

- 3 21700's, so can run the high performance 30T's and 40T's

- SS bezel - nice look!

Initial Readings:

Configured temp calibration by setting the temp to approximate correct, and setting the highest max temperature. It stepped down at the 25 second mark, so took the lumens readings as follows. Using 40T's with solder blobs on top:

- 15840 lumens at start, ~14400 at 25 secs, might have already started dropping (these are maukka calibrated #'s)

- 712 kcd taken at 5 meters, after doing the 30 second test on the same cell charge