Greetings all.

After reading a lot of threads about wrapping P60 drop-ins with aluminum/copper foil, copper tape, soda can strips or copper sheet strips, I decided to purchase a sheet of 3mil copper sheet from Ebay and do some wrapping of my own. I also decided to measure the difference in temperatures to see what all the hype is about.

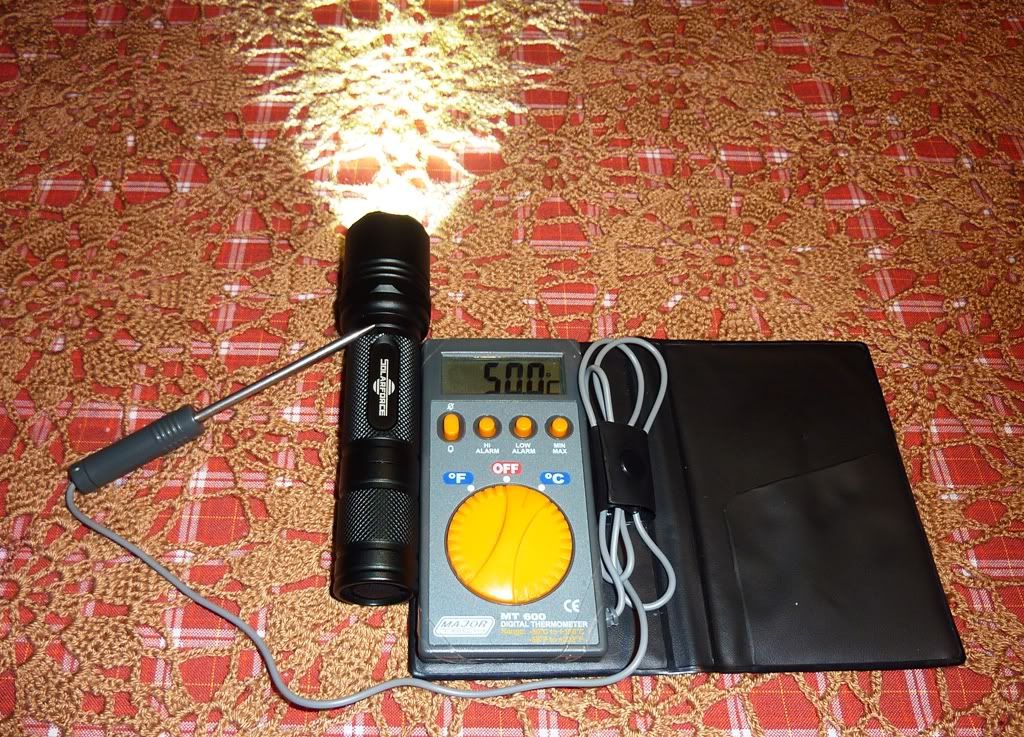

The ingredients:

- Solarforce L2P

- XM-L T6 drop-in with 3.5A (10x7135) 105c Nanjg driver

- 2 x fully charged Trustfire Flames 2400mah

- Pure copper sheet 3mil thick

- Digital thermometer

Unwrapped Measurements:

- Solarforce L2P with normal unwrapped drop-in

- Trustfire Flame battery measuring 4.16v

The resting temperature of the light was 24.9'C:

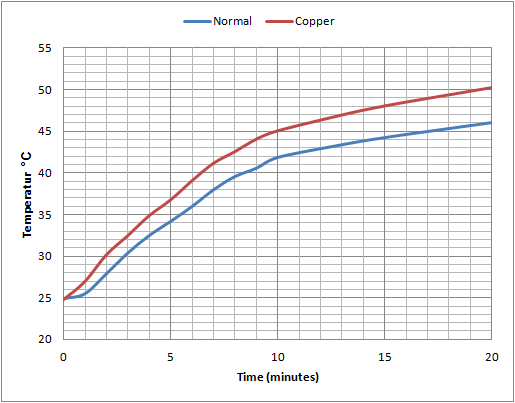

I left the light running on High (3.5A) for 20 minutes and took measurements every minute for the first 10 minutes, and then at 12, 15 and 20 minutes.

After the 20 minutes the battery measured 3.88v

Wrapped Measurements:

I took the whole light apart and left it for an hour to cool down to 24.9'C again while I wrapped the drop-in with the copper sheet.

I used a fresh Trustfire Flame which measured 4.15v

About 6" of copper sheet and the drop-in fits really snug in the L2P host:

Breaking the 50'C barrier

After 20 minutes the light was so warm, I had to go get oven gloves to pick it up and take it apart so that it could cool down. The battery measured 3.92v

Results:

And here are the results:

I think it is fair to say that the copper sheet acts as a very good heat transfer medium from the LED to the P60 Host.

Thanx for watching. Any inputs/comments welcome!

EDIT: Fixed Pictures. See the following threads for good results too: https://budgetlightforum.com/t/-/23586 and https://budgetlightforum.com/t/-/23793