The benefits of direct LED to copper mounting is well documented here on the forums. Copper mcpcb’s without a dielectric layer such as the Sinkpad or Noctigon do help tremendously in allowing LED’s to be overdriven. Overdriven LED’s means more heat and that heat needs to be transferred to the body of the flashlight host in an efficient manner.

P60 setups typically use a brass pill, which is a bottleneck in terms of thermal conductivity compared to the rest of the metal used in the thermal pathway to the body of the flashlight host. Brass has roughly half the thermal conductivity of aluminum, while copper has roughly twice the thermal conductivity of aluminum. Disregarding thermal interface materials such as thermal paste and epoxy the thermal pathway of a P60 setup is:

LED -> MCPCB -> Brass Pill -> Aluminum Reflector -> Flashlight Host

If the Brass pill is a bottleneck what can be done? There aren’t any widely available pills made of better materials such as copper or aluminum. Here is my solution.

My mod helps transfer heat from the copper mcpcb to the aluminum reflector directly without going through the brass pill. The amount of surface area where the small copper strips come into contact with the reflector isn’t that great, but it’s definitely better for heat transfer than going through the brass pill. Heat will still be transferred to the brass pill, just not as much as before with a regular setup.

Here is how I did the mod. First step is to scrape away the dielectric layer of the mcpcb on the edge and to determine how thick the dielectric layer is.

1.58 – 1.3 = 0.28mm thick dielectric layer

Next up is to measure the distance to be bridged between the mcpcb and the reflector. FYI I used a Fasttech XP SMO reflector (SKU 1208506).

Distance between the reflector and mcpcb with dielectric layer: 4.84 – 3.6 = 1.24mm

Distance to be bridged by copper strips: 1.24 + 0.28 = 1.52mm

Here are the copper strips for the mod that were from a piece of copper pipe. I filed them down just a tad bit too much (0.07mm), but in the end it worked out just fine.

Copper strips and LED reflowed onto the mcpcb. The reflow process added 0.08mm in height between the copper strips and the mcpcb. The distance bridged by the copper strips + solder paste is 2.83 – 1.3 = 1.53mm.

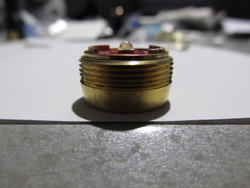

Here are some assembly pics of the dropin. Note the copper strips are above the top lip of the pill. Ceramique thermal paste was used between the mcpcb and the pill, while Fujik was used on the copper strips and on the threads of the reflector. Everything was screwed together tightly and allowed to cure/dry.

FYI the driver used is a Kaidomain v2 8xAMC7135 (3.04A). A XP-G2 driven at this level definitely needs a better thermal pathway; hence the reason for the mod to the Noctigon mcpcb being done. Last thing to do is wrap the dropin with some copper foil and I’ll be good to go.