Below is a list of members who have expressed interest in a thinner(.8mm) board or just responded in the thread with soft numbers next to them. At the moment, there’s enough I interest for me to justify ordering 100 boards but only those with a number next to their name are assured of getting them. Anyone else would be first come first served until they are gone.

The conus price is $.70 each plus $1 for postage, packaging, and paypal for up to 10 pcs then $.75 each plus $.75 for p, p, n p. For orders over 10. Aussies get yours from Mattaus and contact him for pricing etc. I’ll send them anywhere they’ll ship to but you pay the postage. I have about a hundred of them with about half spoken for. This works out to $8 for 10 of them.

USPS 1st class for 1 oz is $1.15 so outside Conus it’s $.70 each (up to 10 pcs) plus postage, packaging, and paypal fees of $1.65. This works out to $8.65 for 10 of them.

Aussies:

Mattaus - 20, 50 shipped to Matt, received

MRsDNF - 6, see Matt

Ejected Filament - 6, see Matt

USA, EU

Me - 100 less …

Djozz - 5, pd, shipped, received

WarHawk-AVG - 10, pd, shipped, received

DBCstm - 10, pd, shipped, received

Texaspyro - 6 10, pd, 4 more shipped, received

Helios

Sirius

Ima4Wheeler - 10, pd, shipped, received

richnpc - 10,pd, shipped, received

Nickelflipper

ruffles- 5, pd, shipped, received

Nitro

Peetz - 10,pd, shipped, received

Jalben - 10, pd, shipped, received

Koyotee - 8, pd, shipped, received

Lithium - 5, pd, shipped, received

Firelight2 - 5, pd, shipped, received

V 2.3 this is the current production model available from Oshpark 10.5mm and coming very soon in a .8 mm thin board.

V1.0 Have a look!

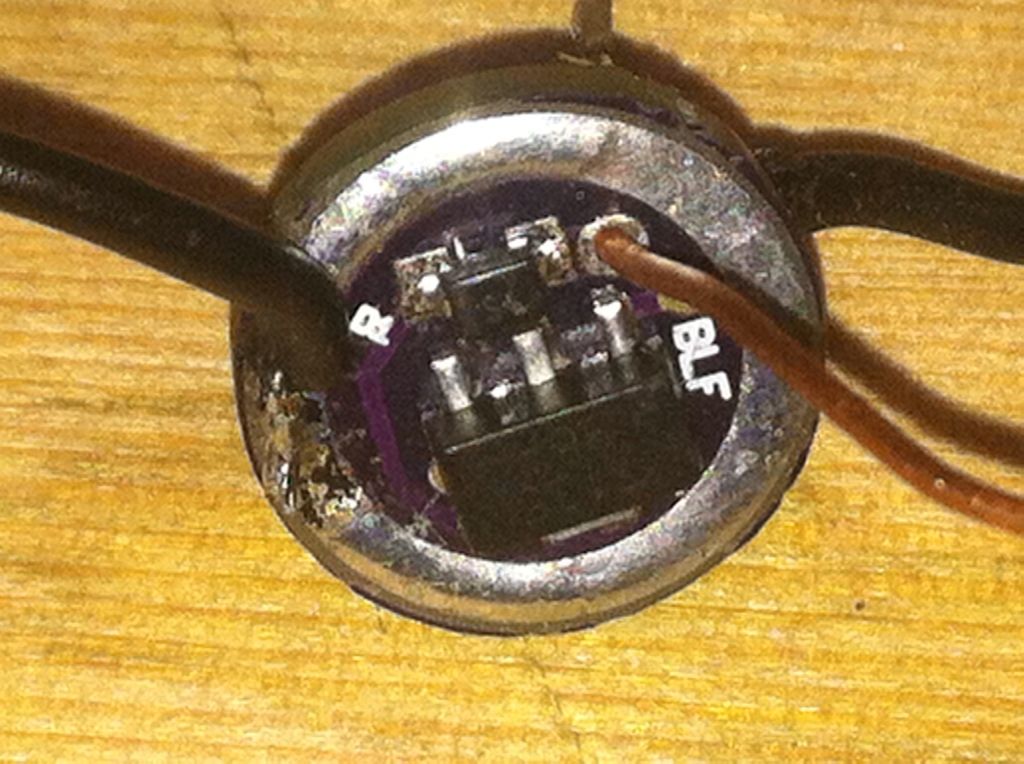

As per request, here are a few pics of the driver w/transplant components. As you can see, my smd soldering isn’t great but it is good enough to work.

As soon as I get a chance(after MRTdiver’s Minimag is done) I’ll attempt to load one of these. DBCstm gets a try as well but there are only 6 boards in this first run so only insane dedicated diyers need apply for a chance at the remaining beta boards.

Just to be clear, one(or a stack) of 7135 chips gets soldered to the ground ring side of the board along with D1. On top of that a B+ contact plate needs to be located with a contact wire running through the board to led+. All of the other components of a nanjg 105C board(mcu, C1, R1&R2, and led-) fit on the other side of the board.

The purpose of this is to have a dedicated liion driver( not some “maybe it’ll fry, maybe it won’t” 3V driver board) for use with 3.7V-4.2V cells in AAA mods. Admittedly a small nitch so I don’t expect a huge demand given the difficulty level but still unique in application.

—-

Some of you may have noticed my query in VOB’s 10mm Sinkpad thread about a linear driver for use in 10440 hosts or anywhere space is at a premium. Well, Matthaus picked up the gauntlet and came up with a board for me and any other diyer silly daring enough to try and swap components from a spacious 105C onto this near sighted, finger cramping, guaranteed to frustrate even the most patient amongst us, single 7135(but stackable) board. I’ve copied his links to the board below:

Top: http://i.imgur.com/aGDYhnh.jpg

Bottom: http://i.imgur.com/0eyLH85.jpg

Stacked: http://i.imgur.com/5Z1a08a.jpg

This is board only. I will have to swap parts from a finished, programmed board onto this and I’m only interested in maybe 10 for myself and before releasing any of them to others I’ll need to verify that it’s possible to do and also works as intended. Matt has done a great job but this board is cramped and extreme care will be needed to avoid shorts but in spite of that for DIY junkies like me it’s something of a must have. The initial run will only be a low number of boards(maybe 20) but if it works and there’s some interest there will be a second run to fill any further need. You need not mention a particular number at this time since we’re at a provisional stage but look it over and post if your interested.