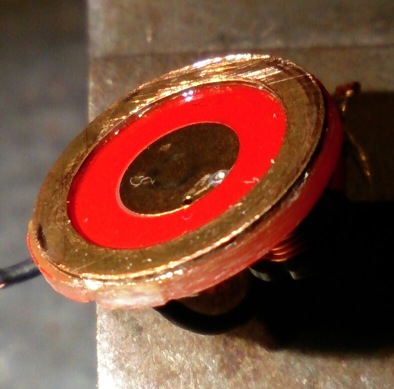

Dale corrected me there painfully ;-) , but the math really promised a bit better than that, could it also be better in real life? Recently I received a nice 'n cheap new AAA Ultrafire with modding potential, there's a thread about it already, (I put a picture of the internal parts over there):

It is really small, not as small as the ITP A3, but smaller than the well known Ultrafire M5.

This was going to be my candidate. For this mod, to stand any chance to get closer to theory than Dale got, the heat connections and the electrical connections had to be taken care of very well. Unfortunately I did not have a nice big-output cool white XM-L2, so this mod had to do with a XM-L2 led with 5D2 tint and 80CRI (T4 bin), that I did have in my modding leds box. That sure is a drawback if you want to go for maximum output, but (famous quote OL ;-) : ) 'it is what it is'.

Some more pictures taking it apart:

The battery side of the driver has a nice extra brass ring soldered that can handle some wear (it is a twisty light), and it does not touch the side so that the twist switch will still work if the anodisation from the threads is worn away, nice! there's some thermal paste under the led board, but the pill is fully anodised; not optimal for heat transfer from board to pill. Weird enough for a twisty, the light has a tail cap!, so the spring can be easily worked on. I tested the material of the spring by sanding some away on the underside: it has that brass-ish colour (bit too red for brass, bit too yellow for copper) through-and-through, would this be one of the famed Beryllium springs? At least it is not iron, so I just left the spring unmodded.

Now for the mod. First the ano on the inside of the pill had to go. It had to be sanded off, but I wanted it as flat as possible as well. So I used some metal part I had somewhere (don't know what it is actually) and sanded the top side of it completely flat. With strips of sanding paper on top of the piece I worked iside the pill to make it bare and flat (that took 1.5 hours  ).

).

I took even a bit more away after taking the picture.

The new led board was a Sinkpad, I have some nice new 10mm Sinkpads, but the alu shelf under the board is rather thin, so I wanted to have the board as close to the edge as possible, so a 16mm Sinpad was sanded down to 12mm, a XM-L2 led was reflowed on it (no pictures of that, forgot to take them), and two beefy led wires were soldered. The reflector is a XP-reflector, so it sits (without retaining ring but with two layers of Kapton tape) on top of the led, letting just the dome through the hole. (Risk with this is that upon tightening the head, the thin silicon layer around the dome is squashed, but because the head is assembled from the top side of the pill, the reflector does not turn around when it is tightened, it is pushed straight down).

Now, the front end of the head could be assembled, I used Arctic Silver5 under the board and tightened everything as good as possible, for the best thermal connection from led-board to shell (I will need that!!). Then on the driver side of the head I bended the led wires into shape

(I should mention that a solder joint on the led board came loose doing that, so I had to disassemble the front end again, remove the board, solder the wire back and assemble it again, these kind of things happen to me all the time, but do not dare to mention everything that I have to redo because I mess things up)

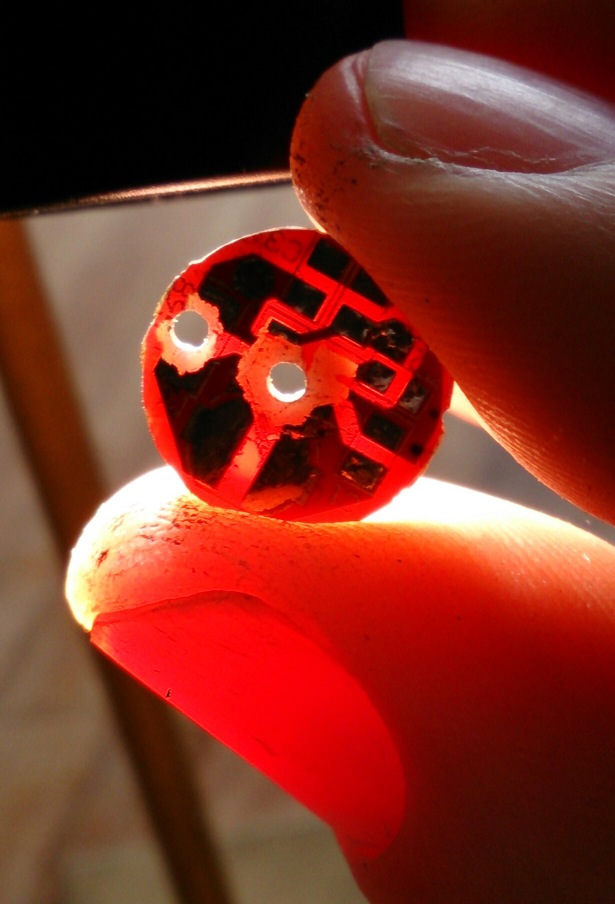

The driver had to become a contact board. On the heat block I removed all components and also removed some traces, I wanted a really clean connection between the led-board and the battery. Two holes were drilled and I soldered a bit of copper on the battery+ pad because the Efest 10440 IMR's are flat top.

The contact board was clamped into place, soldering and sanding:

Light assembled, mod done, glamour pic :-) :

This mod was done mainly for testing the limits of an AAA-light, but the beam is nice, the 5D2 80CRI may be not good for output, it does light things up nicely, with a smooth large hotspot:

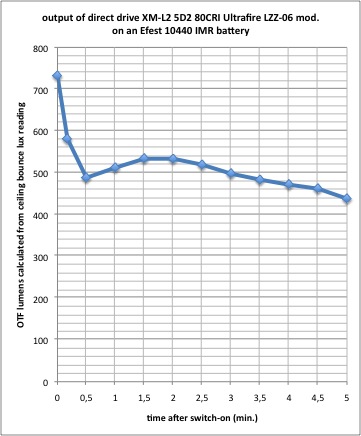

But the real reason for the mod: what does it put out? I did a runtime test of five minutes, tail standing next to the lux-meter, room temperature, no cooling. My theory since the copper boards appeared is that it is not possible to fry a led from heat anymore, if on copper and well mounted. This is certainly a light that puts that theory to the test, and sure enough it survived the five minutes :-) . At five minutes the shell was so hot that it was not just painful, but it would burn my hands (used a tissue to twist it off), but everything was undamaged and the light just worked. Nevertheless I stopped the test after five minutes in fear of frying the thing. Here's the output graph:

It is a d*mn bright light, I'd say. After the intial output drop, it manages to maintain 500+ out-the-front lumens for three minutes (note that the total runtime on a full battery will be less than ten minutes). After 30 seconds the output even rises again, I guess due to lowering of the Vf after warm-up? (so what if I had used a XM-L2 U2 bin instead of T4? The output would be 25% more, so that is 625+ lumens for 3 minutes!)

Conclusion of the mod: It is a very small light, can't expect too much from heatsinking, but good electrical connections and good heat path help a lot! And although this light did not do 1000 lumens, I am happy that I came a bit closer to my theory :-)

. Let DBC sleep, I'm off to bed now anyway.

. Let DBC sleep, I'm off to bed now anyway.