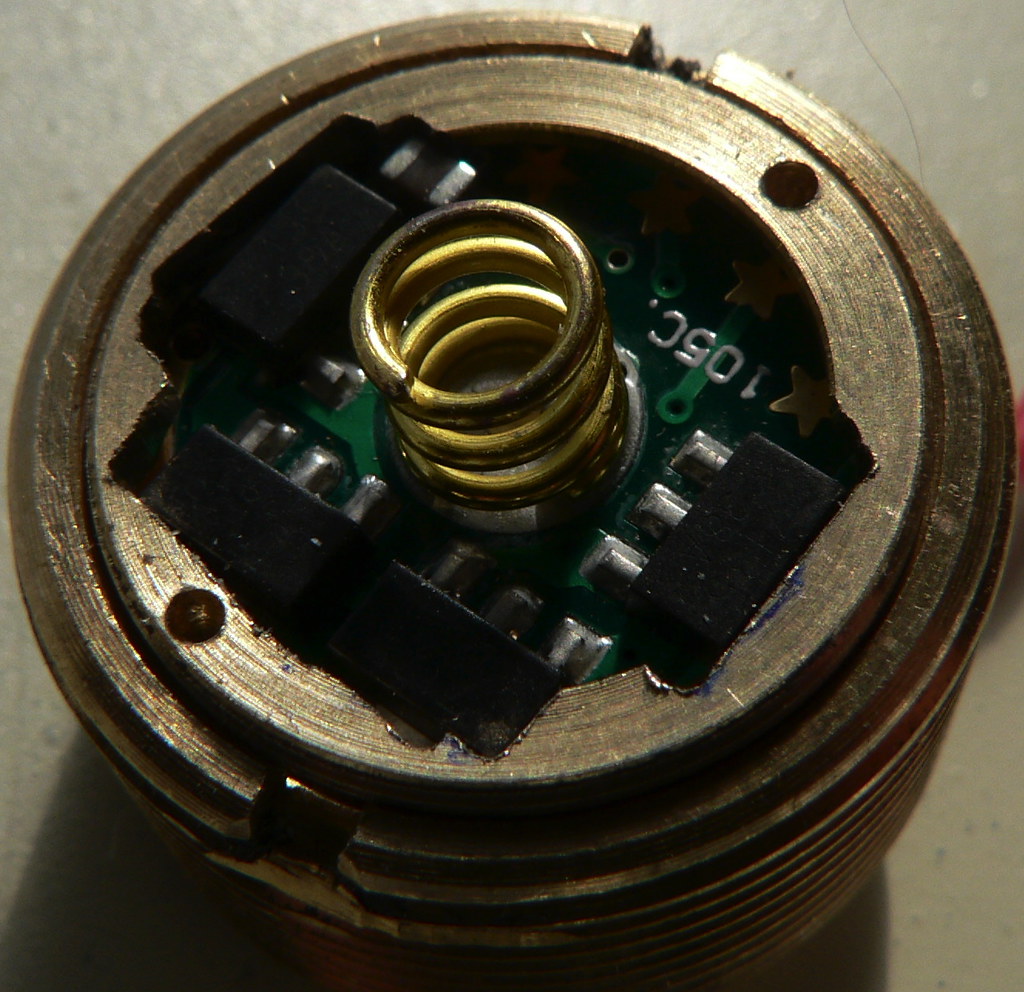

have had a qlite 8*7135 in my s2 which, unless you enlarge the retainer ring to near non-existence, it won’t clear the chips. so I was soldering the driver to the pill’s edge. my problem is the solder doesn’t like the brass pill and it cracks/comes loose if I drop the light. I am considering a one-sided 105/AK-47 with slave board or does anyone have advice on soldering brass? if like to keep it he driver right above 3amps … thanks in advance

I’ve succeeded in fitting three 8*7135 Qlites within enlarged rings, but some of my 8*7135 drivers clearly will never fit. I’ll take one of two paths in the future.

(1) stack 4 additional 7135 chips on a one-sided 105 — helpful video from RMM

— or —

(2) look to this thread for some insight.

I use solder wick wedged between the driver and pill in addition to soldering them together. Seems to hold up so far.

chances are you aren’t getting the pill hot enough to actually wet to it, the solder is just sort of “melting over it”. I have a fairly high-power soldering station, but even that usually isn’t enough. So what I do is:

- take the pill before I start anything else.

- put it driver-end up in my mini-vise

- heat the pill from the bottom with a butane torch until the solder melts on contact with the pill, no direct heat to the solder

- apply a thin layer of solder all the way around the ledge of the pill, then let it cool

Later, now that the solder is already firmly attached to the pill, you should be able to bridge to it from the driver much easier. (you may still want to use some solder wick or something to make it even easier though.)

this forum is the best. I am going to try these ideas. pilotdog I think you are correct in that it’s just “spilling over” I have two soldering irons but think I’m going to use a torch. and gypoflex those are good links… thanks guys

I have done like pilotdog68 did and that works well.

You could try one of the BLF17DD drives from RMM (mtnelectronics). I think they only have components on one side, so should work with a retaining ring.

All good advice above. “Tin” the pill with no driver or LED in it so you can get it hot enough to make a little patch of solder on the rim (careful, it will flow like water on truly hot brass, have some near boiling water handy to drop the hot metal into and the flux will practically explode off leaving it fairly clean, otherwise you may need to dip the whole thing in vinegar and hydrogen peroxide (50-50, 10 minutes) for a while and scrub oxidation off everywhere.

Or file notches in the retaining ring, and pre-backwards-twist the wires so they untwist as you turn the retaining-ring-and-driver into its threads to tighten it down.

(link will find discussion in the thread — should work but only if you set to view 300 comments per page)