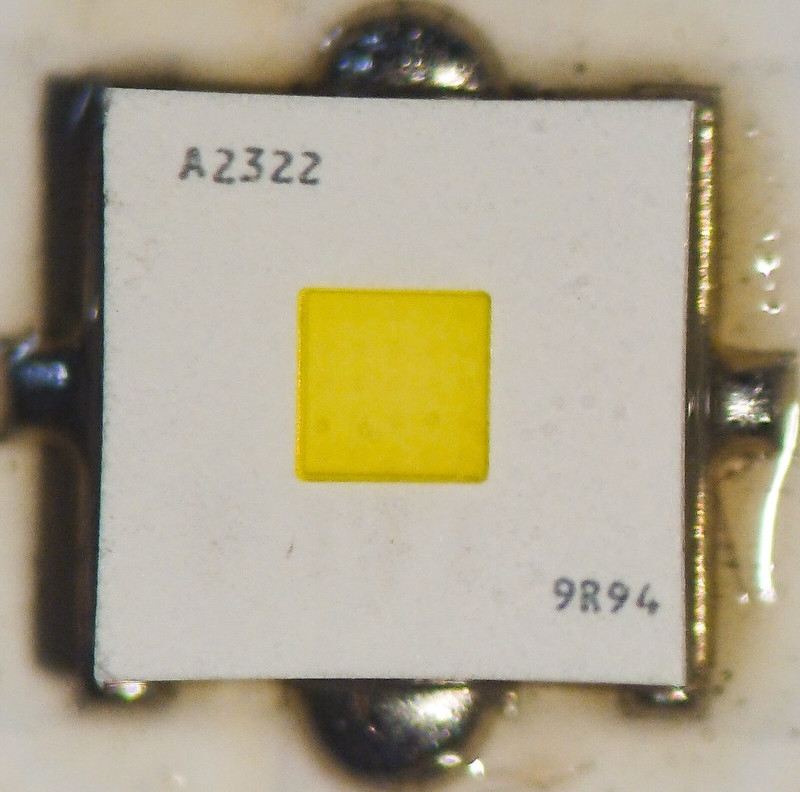

There was some discussion between me and led4power in the White Flat thread about my 1mm2 White Flat test. He found in his test a maximum at 1A higher than me, 5.5A while I found 4.5A. That started me and him questioning my method (I always do that anyway) and that resulted in led4power offering me a bunch of White Flat leds plus 20mm 3030 DTP boards for them, so I could test our different ways of reflowing to see if the difference could be found there. Thanks a lot l4p for providing this substantial amount of parts at no cost for this test :+1:

The set-up, as suggested by led4power:

*3 leds came already reflowed on the 20mm boards by him, done with proper method and equipment and his leadfree solder (SAC305)

*3 leds were reflowed by me with led4power’s SAC305 solder paste (he sent a blob of it in the package), in my usual way: ample solder paste applied by hand, controlled reflow on my heat block at 220 degreesC. For DIY a thoughtful method, but hardly the perfect recommended conditions.

*3 leds were reflowed by my with my own cheap chinese 63/37 leaded solder paste, in my usual way.

So this is an investigation of how our results became different, but at the same time this test gives some general insight in what the influence of different ways and accuracy of reflowing leds is on performance. The White Flat with its high power and very small solder pads is the ultimate subject for testing that.

Earlier, 5 years ago, I found while testing a XM-L2 on 6 widely different XM-boards up to 7 amps, that the DTP vs non-DTP boards made a difference, but once you are DTP, the performance is close, even the thickness of the solder layer hardly mattered. 6x 20mm XML-ledboard comparison . But the XM-L2 has large pads…

And of course this is an opportunity to see performance variation over 9 leds from the same reel, although only per batch of 3 independent of the other variables tested.

As these 9 led tests were about to generate a torrent of numbers, all to be written down and typed in by hand by me (I’m going to develop computer skills when I retire in 14 years ![]() ), I limited the current readings to whole amps, starting at 1A, increasing by 1A each time at precisely a minute, up to 9A. This makes the spacing in the graph a bit rough but it does not affect accuracy or make the results less comparable.

), I limited the current readings to whole amps, starting at 1A, increasing by 1A each time at precisely a minute, up to 9A. This makes the spacing in the graph a bit rough but it does not affect accuracy or make the results less comparable.

Led4power even suggested a preferrable order in which the leds should be tested, so that possible effects of the order on the results were evened out (I do not see order effects btw). And so I did, the leds were tested in the following order:

djozz Pb #1

djozz Pbfree #1

l4p Pbfree #1

l4p Pbfree #2

djozz Pbfree #2

djozz Pb #2

djozz Pbfree #3

l4p Pbfree #3

djozz Pb #3

Testing was done following my usual method testing voltage and output with cooled solid copper mount and my integrating sphere. I did not graph all the voltage results because they were close to identical for all 9 leds and I did not see any relevant data in those numbers. The test results:

My first observation when looking at the data is that the performance of all 9 leds is reasonably close: in the region that most flashlight builds are expected, close to 5A, the output variation in these tests is about 6%. Without measuring you are not going to see that output difference in reality in your flashlight build.

So the first and most important conclusion in my opinion must be that it does not really matter which led you pick, or what solder paste you use, or if your reflow technique is careful DIY or professional: the performance of the White Flat will be similar.

The second observation is that my first test of the 1mm2 White Flat a few months ago showed indeed a clearly worse shedding of heat compared to these 9 tests. These new tests are very comparable to what led4power found at the time. That is the good part, my general output test setup matches l4p’s setup reasonably well after all (at these power levels at least). The bad part is that I was wrong and he was right about my first test, maybe my reflow was bad, or it did matter that the led was reflowed on an ill-fitting 3535 board.

If you go into detail looking at the graph, you may see that apart from led-to-led variations, the tendency seems that led4power’s reflows with same leadfree solder paste gives a bit better performance than my reflows. But also that leaded solder performs a bit better than leadfree. But this may all be pretty insignificant given that it is all too close to the variation that is already present among the 9 different leds.

All that testing was tedious, but I think the results are pretty insightful. I hope that this adds a bit to the general BLF knowledge!