Wow! That was fast! I see. O:)

Despite what I said before, the newer version driver will also let a little bit more current if you stack more and more sense resistors, as it reduces the sense voltage burden. The lower modes will grow higher and higher, though, and if you dare to bypass the sense resistor with a blob of solder or by installing copper sheet or wire instead, all modes will top out in output; the lowest one, if set very low by the driver firmware (like 1%), may not (solution: use the most conductive, thickest sense resistor bridge you can afford). In short, you lose modes in this case.

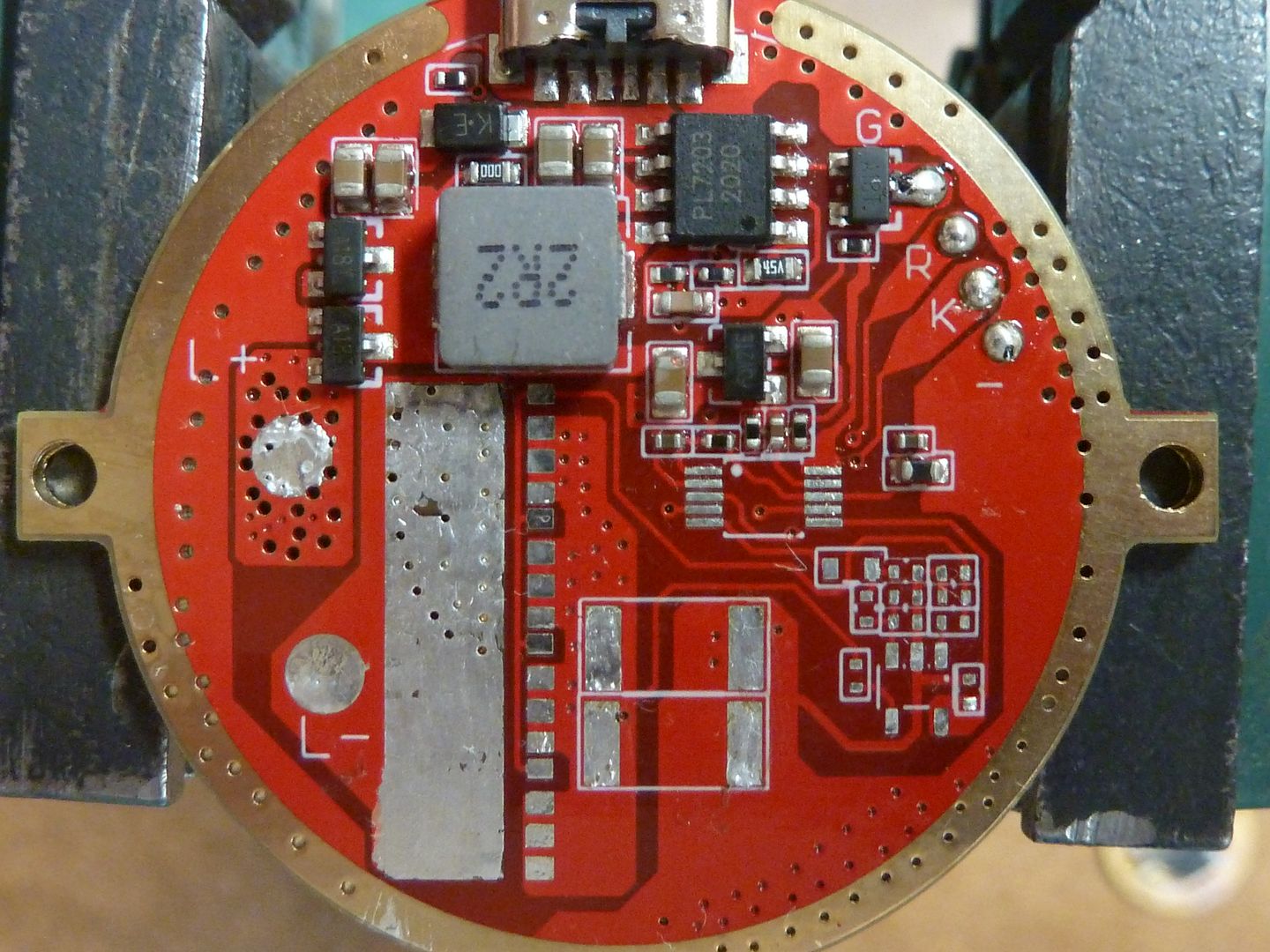

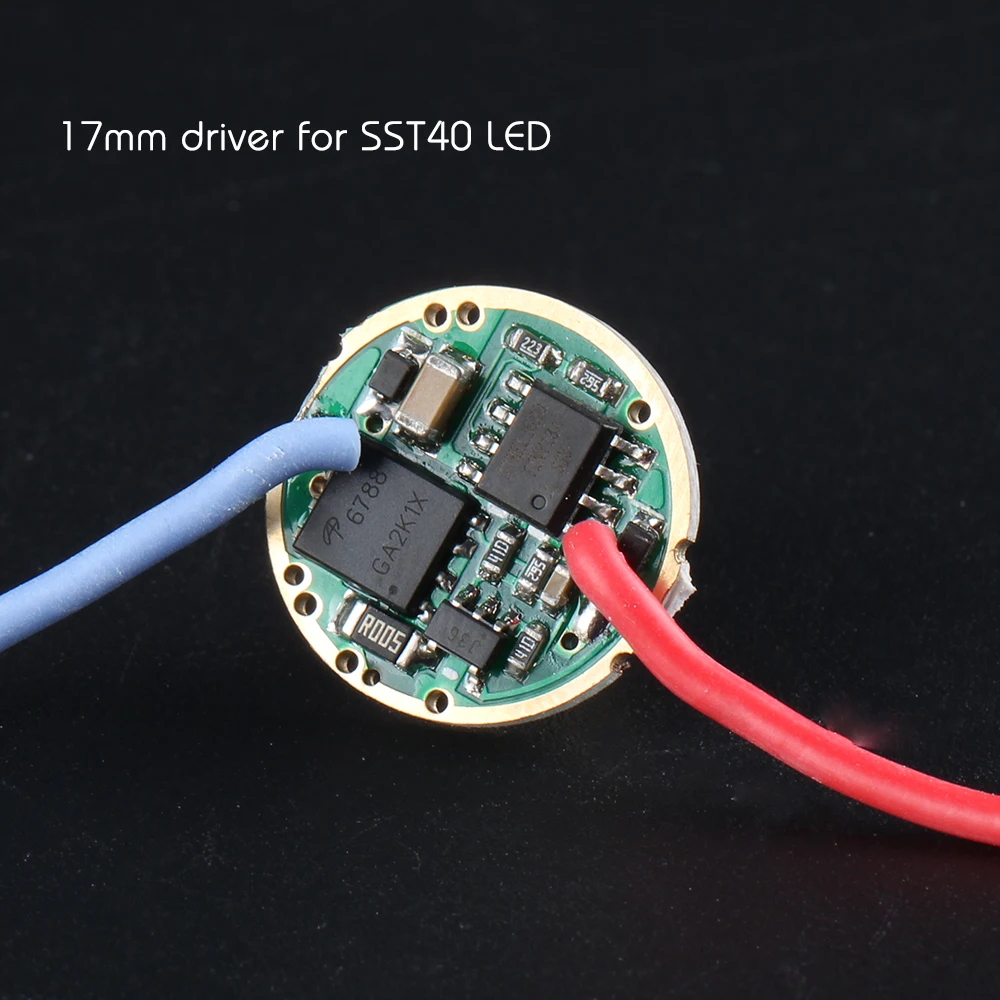

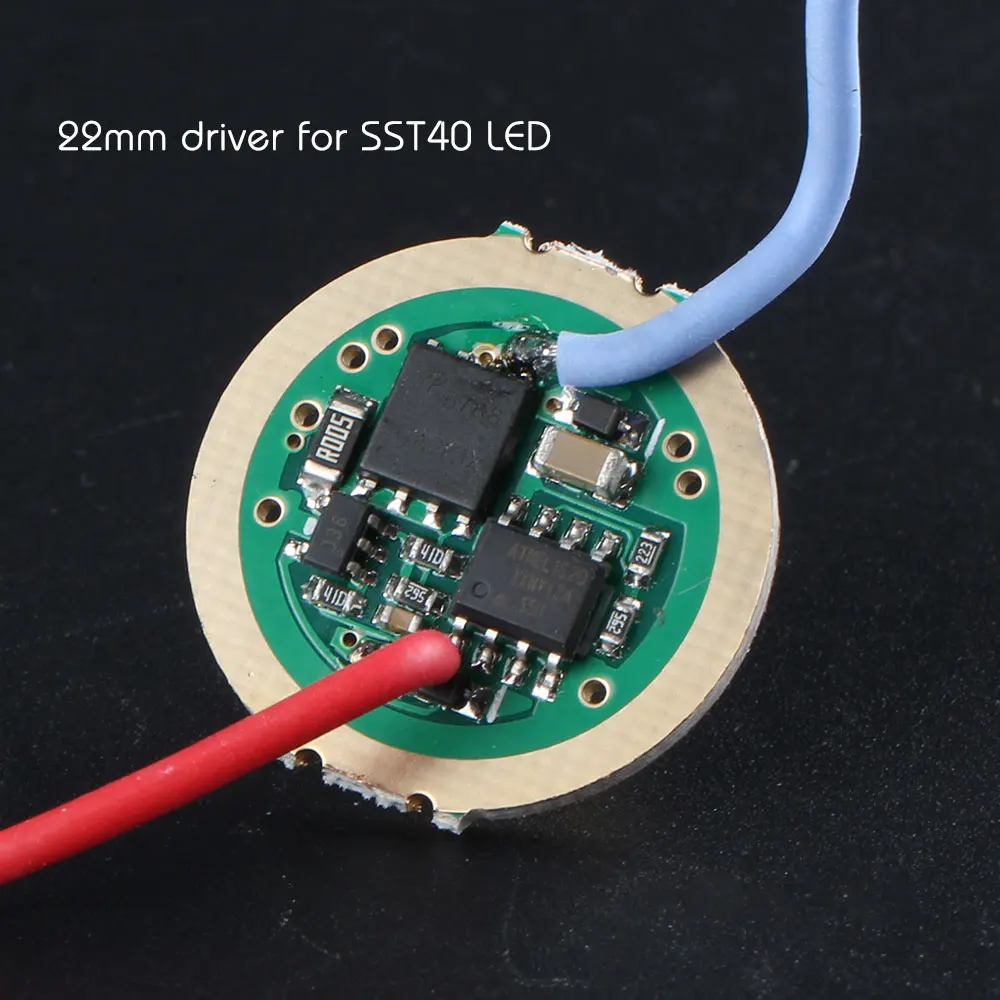

The Convoy “ramping” driver is very solid, really good. Employs a 6788 MOSFET, and just an R005 (5mΩ) sense resistor for up to 8A, so only up to 40mV spent in sense, and the lowest minimum resistance (resistance with the MOSFET “pedal to the metal”, all closed or completely unthrottled) of all linear drivers at Convoy, afaik.

Over time I've learned to appreciate it, despite its weird firmware. It is ideal for gun shooting (hunters), as the mode selection is by series of quick taps: one quick tap, first mode; two quick taps, second mode; three quick taps, third mode. Since the first two modes can be current set with ramping, and the third or special mode can also be set to 100% via the special menu among other options, this means it can be set so that the vibrations of a gun shoot cannot change the output of its flashlight, as all three modes can be easily set equal at 100%.

Here's the sales link of the ∅17/∅22mm ramping driver at Convoy. Oh! :facepalm: I see the chart for the driver mode selection and setting instructions of the driver is missing! Nevermind, the graph is there; it was some sort of connection problem.

Overall I smell a “race for the highest current or output” around here. This is not necessarily a good approach. With the coming of the Osram emitters, with a pretty low Vf and lowest current limits, you need to learn that its drivers must be (or should be) set to limit the maximum current, to avoid any chance of overdriving them. This of course involves looking at the test graphs. However, please bear in mind that not all emitters are equal, and some may have somewhat lower limits. Even if all of them were to stick to no less than the test curves, it is not necessary nor wise to drive them at up to the maximum output current. At these levels, reducing the maximum driving current to let's say ≈80% only renders reliability benefits for the emitter, barely affecting the output. Let's for example see the output graph of a Samsung LH351D 5000K -test- by Texas Ace:

Maximum output current is 9.25A, delivering 2333 lemons.

80% of 9.25 is 7.4, so what do we have at 7.4A? 2220 lemons. This is 2220 / 2333 = 95.15645…% of maximum output at 7.4A, according to test graph information. Do you think this will make a difference to the eye? Go try. x-D

By the way, in the above graph it was easy to see where the maximum output is. Let's take a look at the Reflow conditions tested of Osram KW CSLNM1-KW (White Flat 1mm2) test graph by djozz:

I'll make an small explanation on these duties, just for the sake of it.

So where is the maximum output for these CSLNM1.TG emitters? Is it at 5A? Is it at 6A? Wrong.

djozz only took discrete output measurements each 1A in the latter test (each 0.5A in the former one), and drew straight lines between each discrete value. This is not how the actual output current curve, with continuous measurement or infinite discrete values, looks like.

The actual peak value or maximum in a curve plotted with discrete values and straight lines joining them, is always around the highest discrete value measured for it, and between it and the closest, next highest value. If there are two next highest values, like in the above LH351D curve, then the maximum is spot on the measured point. When there are two maximum discrete values, the peak is between them and higher than both.

In djozz's test the two best emitters peaked a hair above 5.5A, while the lesser performers (excluding the first test's specimen) peaked a little above 5A. In my lightful opinion, I'd probably choose to set my drivers at 4.5A for CSLNM1.TG emitters (the “S” in CSLNM1.TG -1mm²- and CSLPM1.TG -2mm²- means 3030 footprint). There are no tests for the CULNM1.TG or CULPM1.TG ones, so we don't have an idea of the gains for the 4040 footprint. My prediction, though, is that a CULNM1.TG (4040, 1mm²) is barely going to be any better than a CSLNM1.TG (3030, 1mm²). The impact of the footprint may be more noticeable when comparing the CULPM1.TG (4040, 2mm²) to the CSLPM1.TG (3030, 2mm²), but I hardly predict any noticeable gains at stake anyway. Emitter bin is more important in this respect.

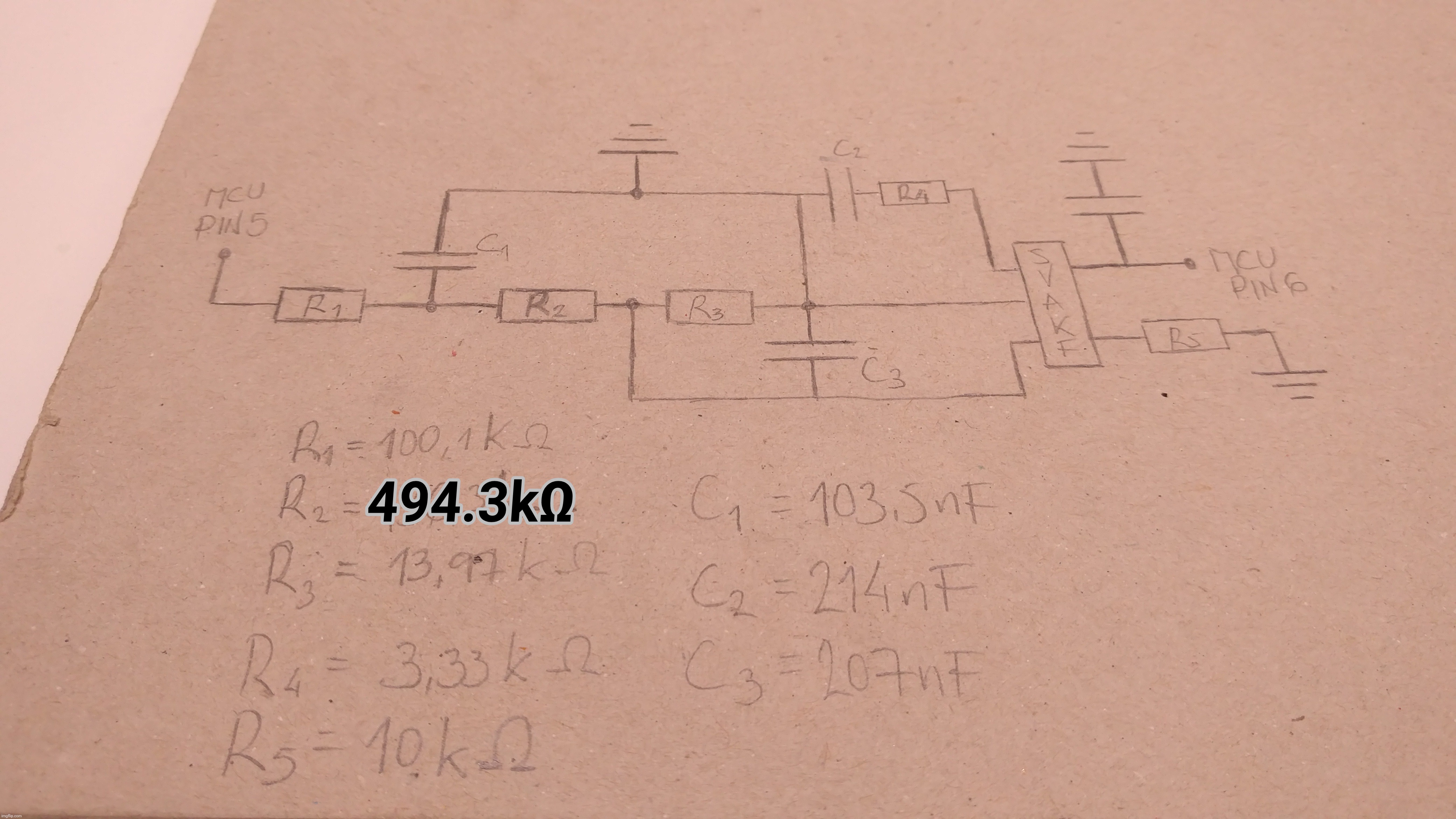

Thanks for the technical contributions, thefreeman, it's enlightening. Still, I am @#$% with all of this. I'll see what I do with the sense voltage dividers. I also have a driver from Kaidomain, the P4000, which looked good on paper. But after inspection, I discovered a fairly gross sense resistor stage of an R050 plus 1R0, which is 47.619mΩ, which is efficiency killer for a buck driver driving a 3ish volt load.

P.S.: Now I understand why my latest flashlight build for a brother had such a small brightness difference between the highest mode, and the second highest, as I swapped the sense resistor in its “new downgraded” driver to an R010, like in the older versions of the driver with smaller sense voltage. :facepalm: