I got a Saik SA-305 in the mail today from keltex78. Great buy and a simple mod.

Yes, I already tore it down. It Barely cleared the package before I had it apart.

I am putting in a Nichia NVSL219AT-H1 4500K, 92 CRI, B10 Bin from Illumination Supply

I will keep the stock reflector and lens (plastic) and I will do some resistance mods to the battery holder and switch.

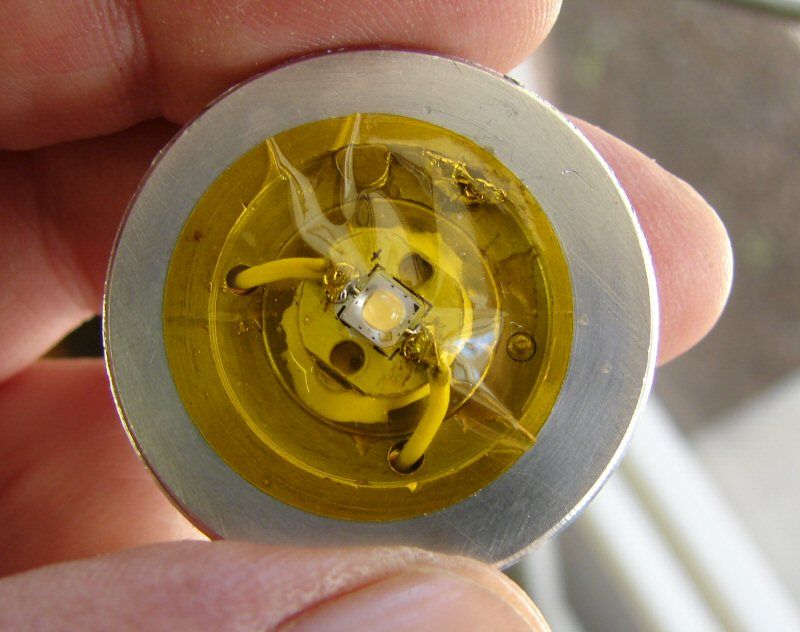

I already changed the stock heat sink into one with a little more heft to it. I used a 1/2" copper coupling, a 3/8" copper end cap and some of the copper I bought from ebay. It's copper pellets (really it's chunks of wire) and it works fine. You can see the cross section and there is solder in there, but there's still a lot of copper in there too. I cut the soldered mess flush with the bottom edge of the original heat sink. As you can see, there's a disc of solder in the top. It's overflow that found it's way around the nooks and crannies when I soldered it all together. It's a thin layer and I probably won't remove it, just smooth it down. Also some of the solder came through the holes in the heat sink and that's good, as it locks it all together in one mass.

I already tore apart the switch and it will have copper replacement parts, as will the battery holder. Hopefully it will cut some of the resistance down in this light.

I'm torn between using one of the V2 8x7135 drivers and take off four 7135 chips to get to 1520ma or maybe only take off 3 and try it with 1900ma.... Or just do it direct drive. I haven't decided yet.

Hopefully, I will have this done this week-end.

Later...........

OK, let's finish this thing up!

V2 8x7135 board, with 3 of the 7135 chips removed, leaving 1900ma. I am using solid wire more and more. The Teflon coated 22ga solid wire I bought from (ebay-navships) is very nice wire. It is not brittle at all and I can bent it to suit with no fear of it breaking. Soldering is so much easier for me now. All you have to do is just touch solid wire and it's immediately hot enough to melt solder. I don't think I will go back to stranded unless there's some need to.

I happened to have some Kapton tape circles, for another project, so I used one to cover the terminals on top. I think this is the best heat sink I have done, as far as heat transfer. When I was soldering this together, I found that as I soldered the + & - on the star, the heat was already out to the edges of the heat sink, as in hot to the touch! That means very rapid transfer of heat all the way through the heat sink.

I stole the battery carrier out of my wife's cut down 2d and replaced hers with the stock carrier. After all, she will never know.

Finished light

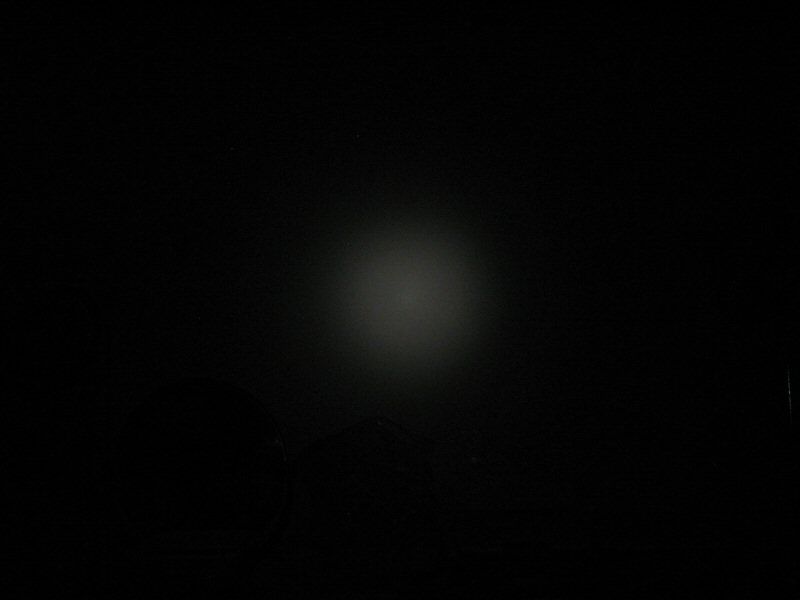

Yes, another reflector with the Krylon treatment. I just can't stand those ringy beams and this one had rings.

Beam Shots

High

Medium

Low - very low - too low for me, but it would be a great night light

High

Medium

Low

That's it! pushing 1900ma into the Nichia seems to work fine. No, I haven't checked the tail cap draw yet, so I can't verify 1900ma, but with five of the 380ma chips, it should be close to that. At least from what the other Nichia I had at 1.4amps was like, I will say this one is definitely brighter. I can feel the body of the light changing temperature in less than a minute, so the heat sink is pulling heat out well. Glad to see that it's doing so good. EDIT: 1.8a+ off the tailcap reading with my analog amp gauge.

Carry on...