A little music while I work.

So, I couldn't resist another EA8, especially when it was already mostly apart when I got it. What is it about the Nitecore lights? It's a love/hate relationship. I really love the look and feel of the EA4 and EA8.

Here you can see the light torn down, torn apart, stripped, gutted, bashed and abused. I am not going to do a huge change with it, you know I never do. I have already gotten the head off the body by using a torch, vise and Crescent wrench. I heated the joint till "goo" started to come out around the seam. Then I tightened the head in the leather jawed vise and used a folded paper towel around the flats on the body and used my big crescent wrench to turn it out. Worked like a charm.

I have already gotten the head off the body by using a torch, vise and Crescent wrench. I heated the joint till "goo" started to come out around the seam. Then I tightened the head in the leather jawed vise and used a folded paper towel around the flats on the body and used my big crescent wrench to turn it out. Worked like a charm.

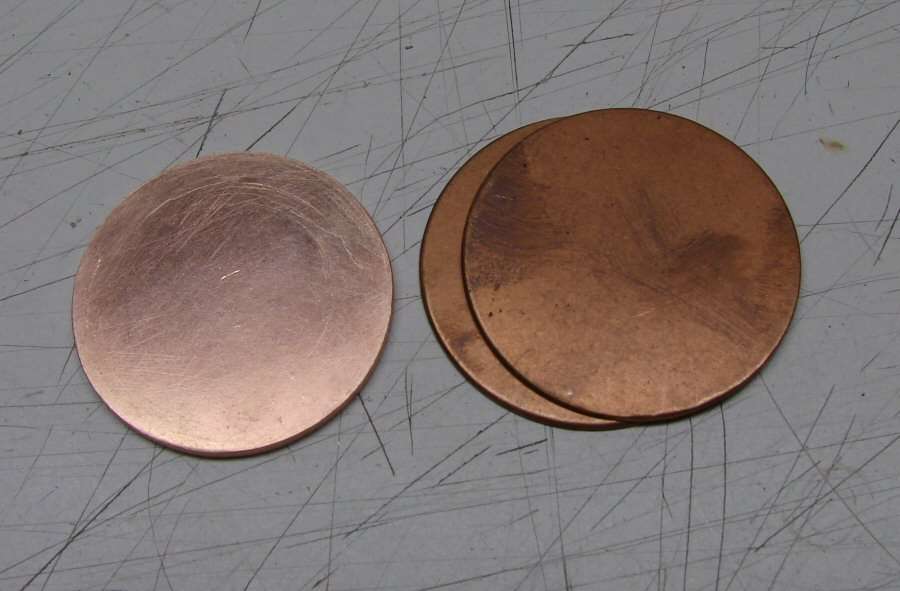

I have removed all the components from the stock driver, which will end up being just a contact plate, as I will be using a DrJones linear NANJG driver in it, with a SMD switch. I'm not making a big heat sink either. I have resolved myself to the fact that the stock plate worked for Nitecore, so I am just going to up the ante by using a copper one in place of it. Notice the copper disc and the copper star next to it. Looks like an XM-L will go in this one and I do believe I am going to make a floody light out of it, by stippling the reflector.

The Copper plate that will replace the stock Aluminum one, is made out of two 36mm discs soldered together. 36mm is too big, so I had to shave the OD down. I chucked up a dremel bit into the drill press and handheld the soldered plate on the drill table, while turning the plate against the bit, (rotating at 3200rpm). Then, when I got real close to the right diameter, I switched to a dremel sanding drum and finished it off a little at a time till the disc will press fit into the body, like the original, well, tighter than the original. I felt that I got lucky, because the disc really looked uniform, so I used calipers to check about 12 spots around the disc. It is no more than .005" out of round. Like I said, I got real lucky. I've never gotten one that close to round before, by hand. Oh, and Jack, I did it by eye.

When I solder discs together I solder one side of one disc and flux the mating side of the other. Then I put lots of pressure on them as I heat and it squeezes out the solder, leaving a very thin layer. Hopefully that makes for better heat transfer.

--------------------------------------------------------------------------------------------

That's all for tonight. It's so nice now, the cool weather has come in and working at night in the garage is fun again. All the whining, bitching and resignation to not do these mods disappears when I get out there and I can leave the world behind for a while and get lost in this modding experience. It's like a drug and I am an addict. I can't hardly walk away even though, at times, I want to...

-------------------------------------------------------------------------------------------

Well, as usual, problems plagued me on this build and not as usual, revelations caused me to think differently, but it's done.

It took me about 3 days and a direct wake up call from another member before I realized that this light was gifted to me. I really did not know in the beginning and sadly, it took time for me to wake up. Besides that I had issues with the build and one of them was totally unexpected. You will see later on.

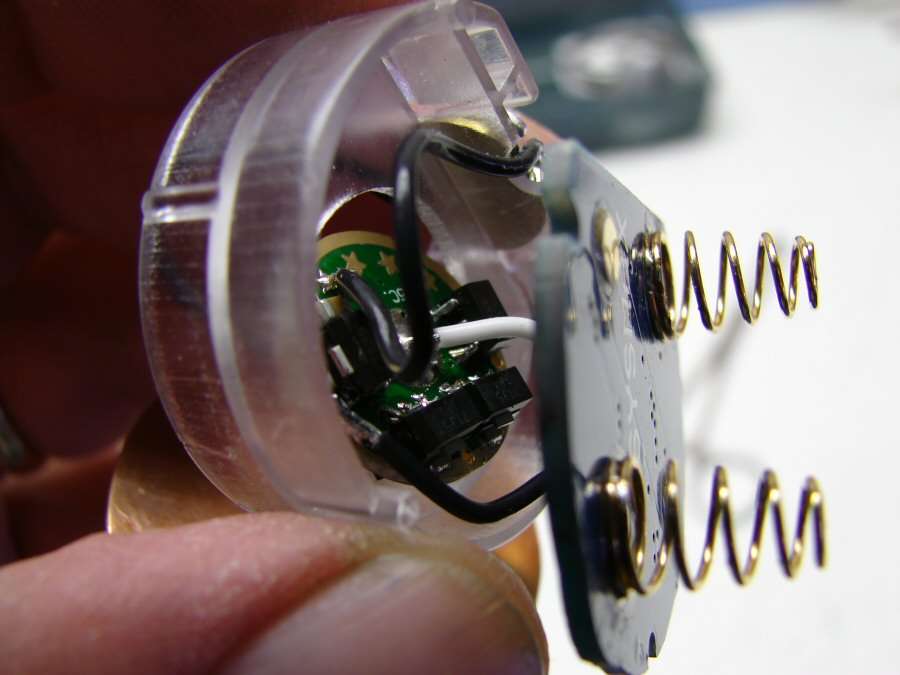

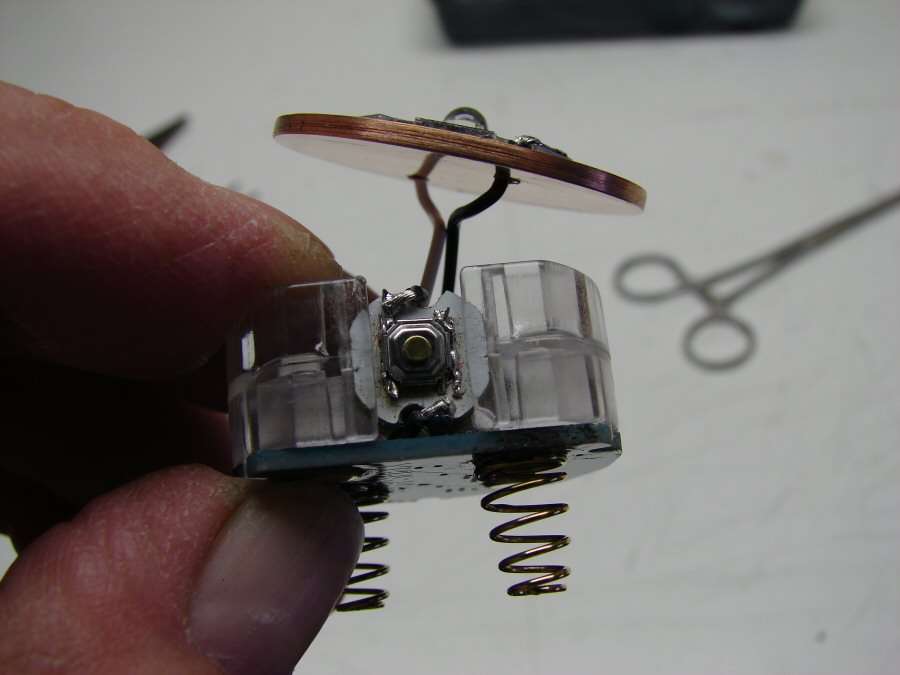

Contact Plate and driver. Driver is inside the stock plastic holder.

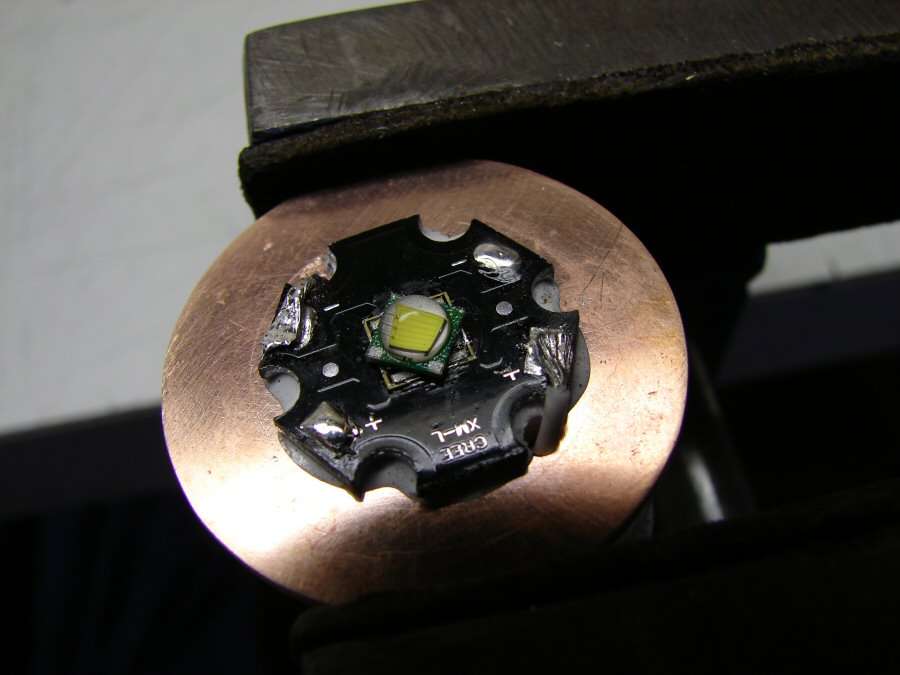

Top side. An XM-L T6 3C is on the copper plate. The driver has 12x380mA chips on it.

SMD switch on an XM-L star

The first time I put this light together, the led spun off the star. What I found is that the soldering (reflow) was not done correctly at all. There was a big gob of solder paste under the led and it had not been reflowed to where it stuck, except by just a thread. I had to remove the star, clean it all up and reflow it myself. I had several of these come from CNQG when they were discounted, now I will have to reflow them all, to make sure they are done right. Kinda, Sorta pissed me right off...

The DrJones driver has two main modes, High and Medium. I figure ramping takes care of all the rest pretty easily.

Oh, I went ahead and stippled the reflector to see if I got a larger spot and more spill. Well, I got a little larger spot and hardly any more spill.

Medium

High

High. I could not hit the end of the pond with any real brightness, so it's not a thrower any more. More of an aborted attempt to be sucessful. Oh well...

That's it. Now that I know it was a giventome light, I will save it for a Christmas giveaway.

Oh, never mind, we do all the time...

Oh, never mind, we do all the time...