I thought I had seen someplace here where a BFL D80 had been fitted with a Cree XHP50, using 2 x 18350 cells. ? But search as I may, I come up with nothing. Can anyone point to such a mod? In particular what reflector or optic fits / works? Thanks all.

Look for a comparison between D80 and x6 reflectors. If the reflector isn’t much shorter you can try a ledil iris. I am using one in my X6 with xhp50. Any one compatible with XML and/or MCE work great

I’ve got a D80 with a XHP70, I had to modify the reflector for that.

I finally got things all together. This was easier than I thought. ![]() I bought an XHP50 on a Noctigon from Richard and a 20 mm driver, his FET driver setup with guppydrv1 and the 6 volt LVP. A couple of Efest 18350’s completed the materials list. While I waited for the parts I soldered a small length of copper braid to the tailcap spring.

I bought an XHP50 on a Noctigon from Richard and a 20 mm driver, his FET driver setup with guppydrv1 and the 6 volt LVP. A couple of Efest 18350’s completed the materials list. While I waited for the parts I soldered a small length of copper braid to the tailcap spring.

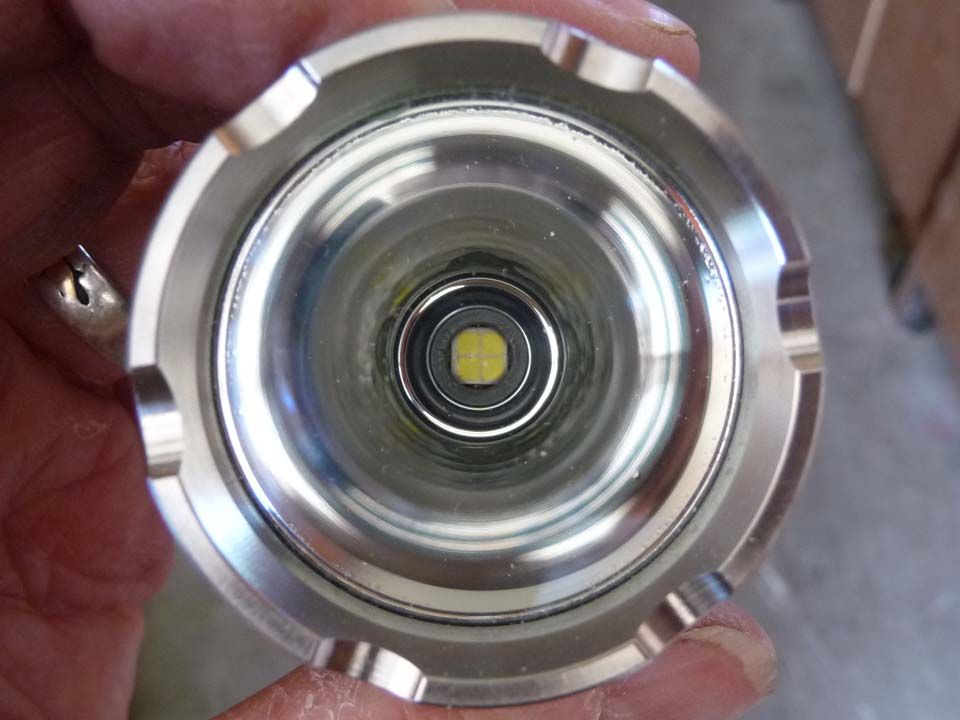

Here’s the XHP50 installed…

The driver in place. It needed a lot of filing and sanding around the perimeter to make it fit…

The efest 18350’s…

Wow! I can’t wait till it’s dark! This is BRIGHT! I’ve never done beamshots so I’ll have to give that a try. I have another D80 … I can try side by sides.

One more thing. I know this is not perfect as it lacks an o-ring where the two tubes join…

But this works. The original BLF D80’s I ordered came with the slightly short tubes. When they made longer tubes available I bought two. So the old “too short” tubes were lurking on the shelf and I said what the heck, let’s see. With the tubes mated the multimeter indicated continuity from one end to the other. So, I screwed the twin tubes to the head, slipped in a couple button non-protected cells. It works.

Maybe wrap the joint with some silicone tape?

Nice mod ![]()

I would use ptfe thread tape, or a smear of silicone sealant on the join without an o-ring, if water proofing is important.

Nice mod! does it get hot?

Just realised that this would insulate the threads! So maybe just a smear of vaseline would be better ![]()

Just realised that my prvious suggestion would insulate the threads! So maybe just a smear of vaseline would be better ![]()

(Been doing too much plumbing recently!)

Hot! Funny you should mention that. Yes, it does and it does not take too long. I should dig out my IR thermometer and measure to see what my hand is feeling.

Re the tape on threads… the tape would be okay as the conductivity happens at the machines faces where the tubes touch ends. The threads are insulative because of the anodizing. My biggest objection to teflon tape would be the color (white) would be very obvious against the dark anodizing.

Stretch the teflon tape to narrow it and apply only where it should end up hidden. Old plumbers trick to make shower-heads look prettier.

If there’s enough space in the threads you can also twist the teflon tape into a rope first to help make them tight. This can also be used for temporary packing on a faucet till you can get the proper graphite string.

Phil

My first attempt at beam shots didn’t look all that great. Will try again.

But I have some amp measurements taken with the tailcap off with a UNI-T UT210E using a short pece of #6 copper wire as the connection across the negative battery end and the tube. (this is a MTN DD/FET driver)

With efest purple IMR 18350, 700 mah cells, turbo gave a reading of 6.15 amps falling to 5.75 after 20 seconds.

Running a pair of 18650 Samsung 30Q in the twin tubes I got 6.50 amps falling to 6.35.

No wonder it gets hot quick on turbo!

What I really need now is an integration sphere…

Wow!

Well, this may be a tad off-topic but, now that you were speaking about sealing/lubing flashlight tubes’ threads, what about using standard thermal paste for this? It’s cheap enough, should enhance thermal transfer while still improving somewhat the watertightness ability of the tube.

Cheers :partying_face:

I apologize for necromancing this thread, but after accidentally letting the magic smoke out of the driver on my BLF D80 :person_facepalming: , I was considering these exact mods. It’s neat (not to mention reassuring) to see that someone else has already gotten it to work.

Did you find the problem?

Who, me? I was fitting a new reflector into the D80; after getting the LED hole filed large enough for the stock LED, I put the whole thing back together and turned it on.

poof DRIVER DED

I could just replace the driver with an A6 style driver or something, but as the woman allegedly said, “If it’s worth doing, it’s worth overdoing.” Also, as the man once said, “If it ain’t broke, you’re not trying hard enough.”