Thanks!!

I had a reply e-mail from Shezchan Homesafety this morning about the original stock drivers in the UF-1508.

IF the driver is a single mode driver then it is good for up to 3 series (12volt), the three mode drivers are for 2 series (8.4v) only

Might be useful info for someone in future.

When I started on this ‘tower project’ I initially ordered a Single UF-1508 from Amazon…a ‘local’ European supplier. I then ordered direct from alibaba and Shezan HomeSafety in China.

The chinese order arrived within 5 days, then the replacement parts also arrived within 5 days…and 15 days later i was still waiting for the ‘local’ parts to arrive.

Well the Amazon order arrived yesterday…lens also broken. umm am I just unlucky or does the cosmos just want me to receive broken think through the post…or I have a dodgy postman!!

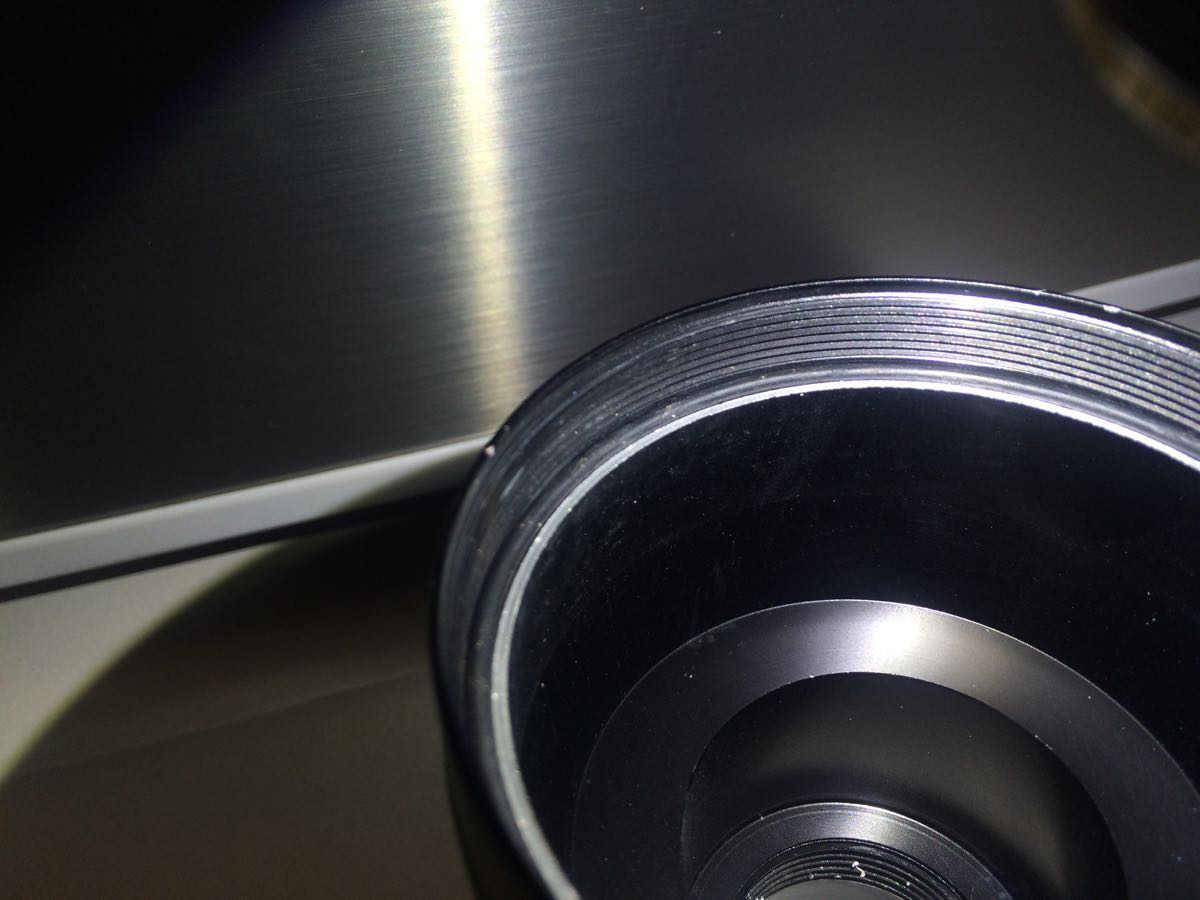

Inside the 75mm head, the lens sits on an ‘o’ ring. Well it is supposed to , but the groove for the ring is too deep, so the ring disappears into the groove and the lens sits on the metal ridge.

Ummm . well 2 minutes on the lathe sorted that out. Yes you can grip the head, although it is angled, in the lathe chuck and get a tool inside to machine off the height off the rim. need to take off about 0.75mm. 1mm is too much as I discovered and the ring only just sits in place and needed superglueing in. I had three heads to play with so no issue.

Also yesterday my mates Searcher arrived

The XSearcher did not last long enough to test its beam pattern. It arrived in the morning he went home to collect it, and before it was dark, the pill has died. It was putting out light during the day, but while trying to get to grips with the ‘twist for single or triple mode’ selection…it went off then failed to come on again.

Tested the switch…it is good, tested the supplied protected batteries, they work in my UF-1508.

But the pill is dead, tried applying g8.4 volts direct to it …and nada…dead as a dodo within about 3 hour of unpacking it. E-mail sent to supplier

Here are some pics

Size of head

Hidden ’o’ring

After machine work, O ring can now support the lens

1 2 or 3 cells

Next to the Nightmaster XSearcher

Mine arrived a couple of days ago, haven’t had a chance to try the new lens but I’ll update when I do. I see what you mean about the O-ring, that lathe clamping though, I don’t think I have the balls to try that. That being said I might have to, this lens is thicker. I’m thinking instead of just gripping that thin edge I would 3D print up a “collet” that fits in all those grooves. If somebody buys one of these without a lathe I would suggest just putting something like some solid copper wire in the bottom of the O-ring groove to space it up. The lens that came with mine is surprisingly good, much better than my 1405, seems like it’s all down to luck of how new the mold was when it made. Going to throw an LED in it soon so see what it will do, stock is pretty terrible, like 118kcd.

I was skeptical that it would hold in the lsthe too, but it was suprisingly solid. Just get the back of the unit butted up against the chuck and all is good. Freshly sharpened tool, a bit of lube and a thin cut.

I’d certainly give it a try before going to the hassle of making 3D printed collar for a 2 minute lathe job.

Your images are huge: 900px × 1,200px

Can you edit them to put a number (like say 30) into the “OPTIONAL relative width %” line so they display smaller?

Then people can click them to see the full size, but they don’t overload scrolling and small screens.

I guess because I use a big screen at home I thought that size looked OK. They were my reduced size images ! A lot of them started out as 5360 wide, the 1200 is my reducec size !

I’ll reduce them all again if it helps then re FTP them to my server later tonight. Easier than going through my various posts and editing each photo line.

Used to other forums where the forum software auto sizes them….think CPF does that, pretty sure the ES electric vehicle forum does too

Sorry

There you go , all small for you ![]()

Whats wrong with these beams? This is what aspheric throwers do. Close range the die image is going to be out of focus. The ring artifacts are from reflected light within the bezel. You need to matte- black out all the reflections and glossy surfaces, or DIY a waiven collar to block and re-direct them.

I bought some basic bike lights from MyLED.com ( website seems dead now)

Thos basic bike lights were alloy housings with a flat glass and a reflector.

What was interesting about the reflector was that at the LED end of the reflector cone, there was a plastic fitting that fitted tightly over the square of the LED die. You could take the LED and its PCB out of the housing and clip the reflector to the LED, turn it upside down and the reflector would stay on. It actually took a good tug to get the reflector to come off, and a reasonable force to fit the reflector back on the LED.

I was considering if I could have made/ moulded/machined something similar for these UF-1508 lamps. but the clip on piece would be a smooth internal ‘reflector shape’ but made of a matte material. It would sit on the LED, on top of the pill, but not so tall or wide as to interfere with the screw / focus/ zoom function of the lens head.

On the original pills, the plastic cap that screws in to secure the LED PCB, and the lens housing I did eventually paint internally with a matte paint, but could never get rid of the reflected rings. The problem is that the internal surface of the pill, the housing etc all have too many flats and ledges that create reflections.

Oh ok… how was the center spot die focus? Did you ever have difficulty getting the die surface to focus a clear image? That aspect looks pretty good.

It’s probably the black cup shaped retainer acting as a reflector, because it’s not flat / matte black, and the outer rim of the brass pill giving those rings.

Black board paint should solve it.

Aw, gee. I guess that would be a foolish thing to do …

I wonder if Ruby et al. will clean up their production.