Old Lumens you never cease to amaze…

Your amazed - I’m amazed. I really didn’t think it would come out as good as it did. I mean all the cuts with a hand saw and no design other than in my mind’s eye. I was fairly amazed that it doesn’t bind and that it’s about as square as I could ask for.

I'm not a technical person and I don't consider myself knowledgeable. I just have a knack at being able to look at something and within a few seconds I can see how it's going to turn out (most of the time). Sometimes it turns out better in the trash can, LOL. My wife thinks I'm the "fix it" god. She's naive, that's why she married me, but she's learning...

but she's learning...

Thanks, to everyone who watched this crazy drill press build.

Very cool. Enjoyed watching!

Keith

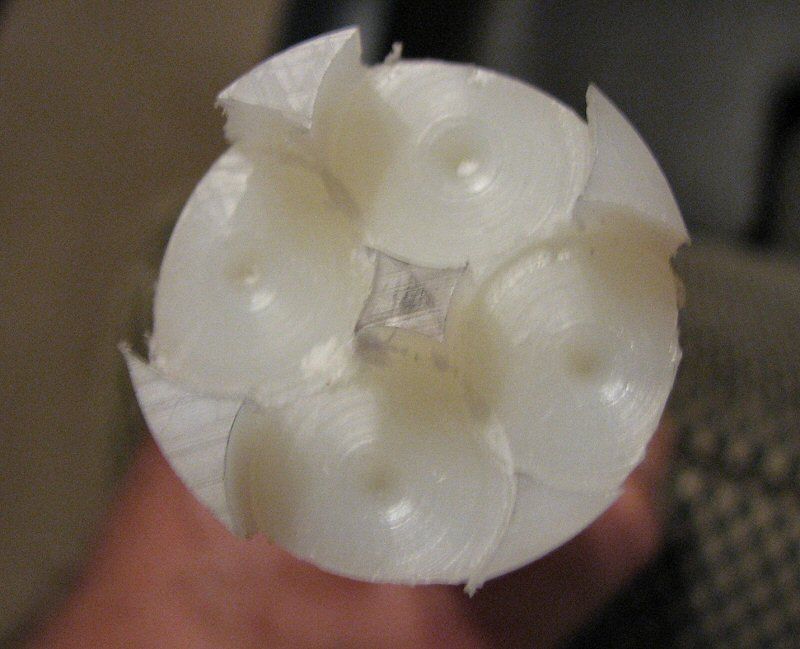

I had to try it out when I got home tonight. Really, the whole purpose for this adventure is to be able to drill Plastic rod, to make 4/8/12 AA Battery Holders. I have tried to drill them by hand, but they need to be precise and I can't do that by hand.

I believe I will be able to do them with this drill press. It is much more of a pain in the arse than a table top drill press, but it can be done.

This is a first attempt and it is not good, but I do know more from trying this one. I messed up one of the holes because I did not have the rod stock tight enough in the vise and it moved. I also didn't have the spacing tight enough, but that is not the fault of the drill press. I can drill straight holes now, with the press. I have to set up each hole one at a time, because I have to move the drill out of the way each time I turn the part, but I will figure that out later.

I can say this is 100% better than anything I have tried by hand and I will be able to make a holder this way.

Whooppee!!

I've seen that kind of holder before and always wondered how hard it would be to made them. And you are just doing that.. nice. :D

Its "Fivemega" design, right?

Again, another nice creation. Well done. looking forward to see the completed battery holder.

Finishing touches include more supports to keep the drill in place and venting.

A rod will now keep the drill from moving up

The block that I kept talking about, to center the drill better.

Intake air vents

Exhaust air vents.

I think that's it!

Similar in the fact that it’s for 4/8/12 AA NiMHs.

Other than that, it's not similar at all. The ones made by Five Mega and (I think modcod), are well made machined holders, that have evolved into the best holders in the market. Holders that will last for years and can be counted on to work.

The ones I THINK I'm going to make are hack jobs and I doubt I ever will really get them made. The first problem is that the holder needs to be made of plastic rod stock that is a larger diameter than is necessary, so it can be turned down to the exact diameter needed, in order to have some "meat" left in it.

I do not have a lathe, so I am trying to use plastic rod stock that is a smaller diameter than the maglite, so it will not have near enough "meat" and will be inherently weak.

Five Mega also has the best design and I cannot/will not copy it completely. I don't feel that is right or fair, so I would have to do it "my way" and for this battery holder, my way is not the right way. I doubt I will ever get them completed. I will make one, but probably just end up putting it on the shelf. My concern is with the end user and I just don't want to sell a weak or wobbly hack job holder to anyone.

Like Don might say, I need more tape and dowels, but that is not something I want to sell to someone. I wouldn't want to sell a bad battery holder that I made. I did that once and I regret it.

I just don't have the bucks to sink into Five Mega holders for maglite builds. Hell if I went to CPF and bought all the stuff for making flashlights "the right way", I couldn't ever sell them. They would be $175+ a piece.

In the long run making "pretty hosts" works out best, then the buyer can build it themselves and they can either "do it right" or "hack job" it. Whichever way they want.

No matter what I will still get use out of the drill press. Every time I want to drill holes in a heat sink or in a maglite body, I will make use of the press, so it's still a good idea.

I also find these holders interesting, seems possible to make them yourself:

http://www.cpfmarketplace.com/mp/showthread.php?96929-MagD-Battery-Adapter

I also thought about getting holders like the ones you are building printed in plastic.. but I dont really have a use for them. ;)

You are building that stuff for yourself, to play and experiment. But still it can be a great inspiration for others, thats why I find it fantastic that you post such a detailed documentation of almost every step. :)

A drill press is a great tool btw, not only for flashlights. :D But its also useful to make a Minimag P60.. oh wait, thats a flashlight. :X

What's the First thing you check, when you feel your Tabletop drill press is not level?

That's not what I did (I didn't check the table first).

first).

I now have a level table, a level drill press and a level vise. Horizontal and Vertical. I think boring out Maglites will go better now.

Every time I think I know what I am doing............

You know what you’re doing, just didn’t know what the table was doing . . heck, you caught the problem before going through the side of the tube like I might well have done.

I just saw this thread for the first time, and I must add my own amazement and respect to your handiwork.

Well done, yet again !!!

Well it’s really great to see you back amongst the living. You have been missed……. not by me of course……. but by some of the members. ![]()

![]()

0:)

That’s pretty clever to me.

I haven’t used my hand saws for too long. Does that model have a “lock on” switch?

Some thoughts: If you’re running it for extended periods, a shopvac on the exhaust with maybe a “T” for debris might be nifty. I’ve burned a drill motor using it in a vise for polishing. A cleat across the top might help stiffen it. If at all possible, this should be bolted down. It might not be convenient, but if this puppy jams, your arm could snap before you could let go. Typing one handed sucks. You obviously have both skill and experience so this is meant more to help those with less.