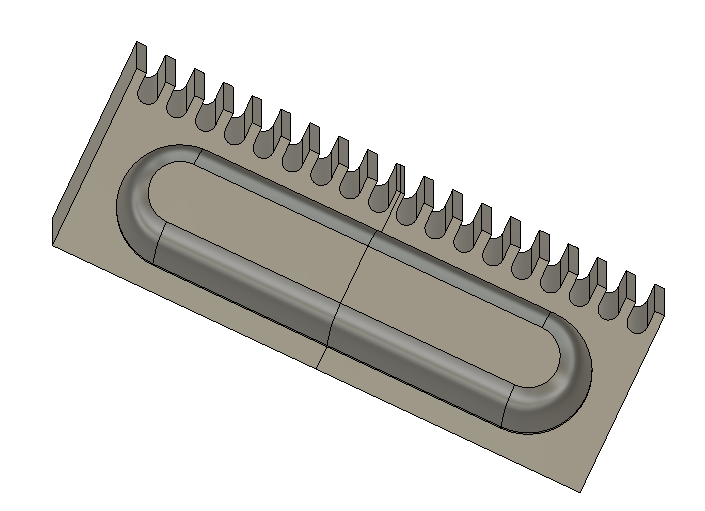

something like this,

drivers in the base and similar finning down the back

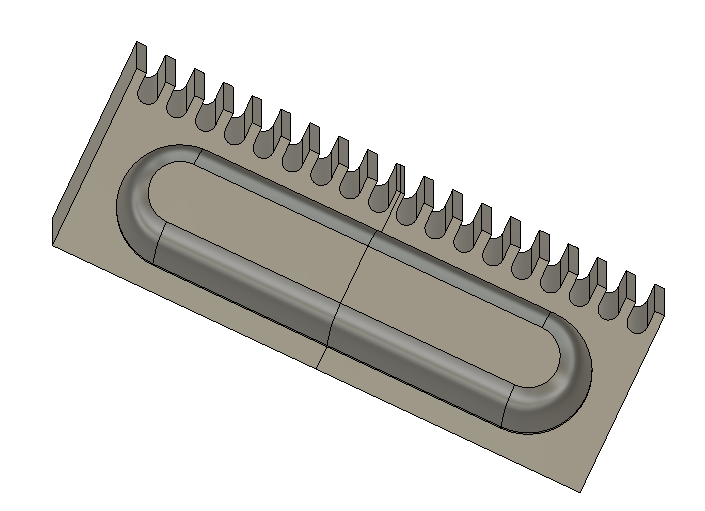

something like this,

drivers in the base and similar finning down the back

Stop talking Chinese and speak English so we can understand what your talking about. ![]()

Oh, so it is automated. I just didn’t notice any steppers on this rig -

From my understanding car voltage spikes can rise above 27v but those are usually in extreme cases like starting the engine. I’m not much of an expert so I don’t know how to clamp the volts. Nor do I know how pertinent it is???

perhaps something like this may be the go

updated pic

I don’t know about the spike killer but I’m green with envy over the mill ![]()

the mill is still very much a learning curve, I should have gone for closed loop steppers

remember that if you ever decide to dabble in cnc

unfortunately it has given me a taste of what’s possible.

flashlight hobby expensive na. I can see 20 k disappearing easily in cnc.

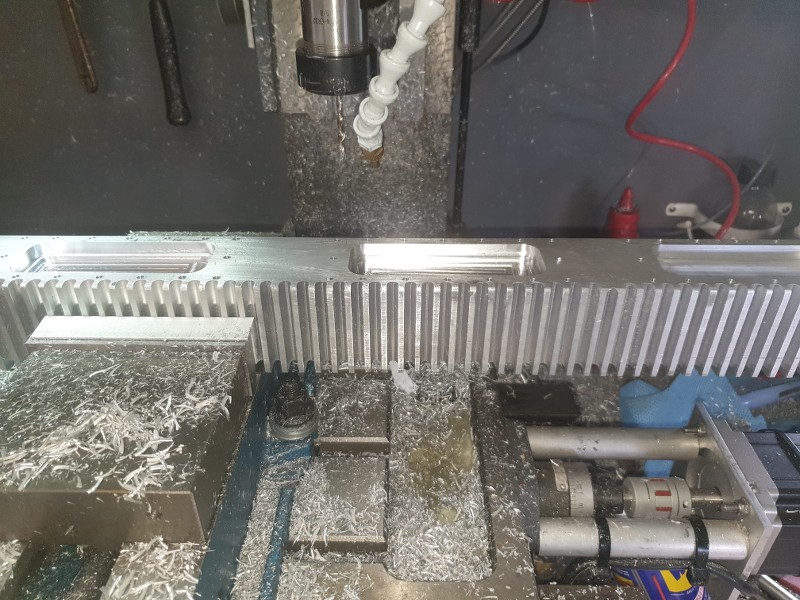

A little bit of progress

about half way through the fins

Bit more progress

fins completed.

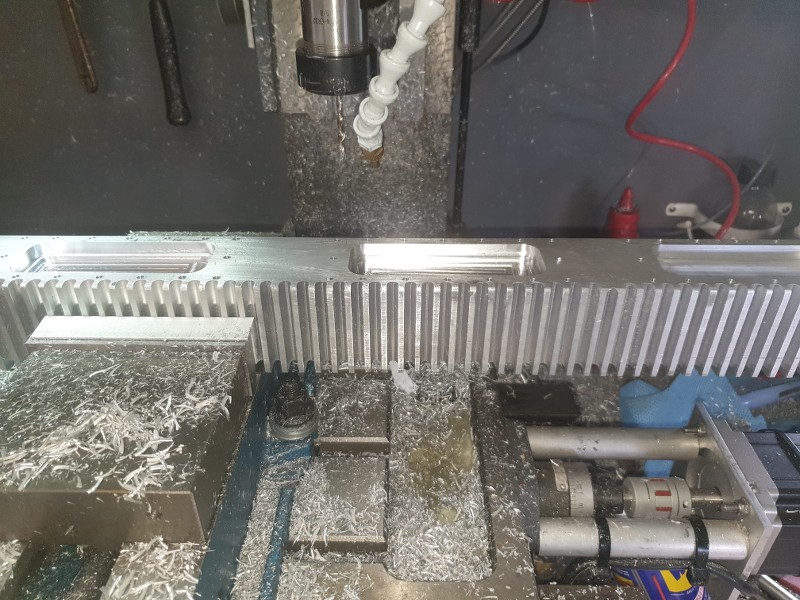

Machining pockets for drivers

pockets finished holes drilled

five and a half hours so far,

next to machine holes for leds/reflectors.

Are they Neil or Tim?

Looks good so far.

I know who you are talking about ![]() Translation to US name would be Huckleberry

Translation to US name would be Huckleberry

tapped the holes this arv using these taps

used the cordless drill worked unreal (m4)

I would aware using such taps for serious project. As most cheap hss drills (also coated with some TiN), they seems to be hardened in big mesh container (as nail and screws). As result some of them are glass hard and can be broken very, very easily. Those ones brown coated seems to got more accurate tempering cycle.

thanks kiriba-ru I may grab some of those to try.

good thing about the round shank ones is they slip in the chuck instead of breaking

A little more progress today.

cut and drilled the front plates.

the fun part comes next

a bit of practice on some wood.

This is the best light bar(thermally managed wise)build I have ever seen. And possibly the best light bar period! Dude you rock!!!

+1 on this.

Its also being built on his own home made NC mill. Loving your work LTP.

a little more progress today made 3 plates for the base

this machine rocks for drilling !

the trial unit still going strong on the front of the car, no driver issues.

You are getting lazy in your old age. What happened to a bit of blue, scriber and centre punch?

cant find the scriber or the centre punch .

cut the lenses

these are Lexan apparently tougher, but acrylic is more scratch resistant.

can allways make more if needed.

started on the pockets for the led’s/reflectors

next pass is with a ball mill then a skim for the leds