Look at the units, it do the calculations from volt to ohms.

The meter shows 60uOhm.

That settles the question. Can’t argue with the number coming from very impressive looking instrument. Thanks.

Mmm sorry, the meter is actually showing the calculated resistance. It's about twice the value I had predicted comparing copper vs NdFeB conductance values, at least for the ∅8mm piece. ![]()

Interconnecting accessory approved!

Cheers ^:)

There is some tolerance when measuring that low resistance, it might be close to your predicted value or it might be the other way, but it will be insignificant compared to the internal resistance in a battery.

I could have done it more precise, but they I would have to use both a power supply with constant current output and a DMM with with 0.01uV resolution.

serica, welcome to BLF. A tad off-topic message, my dear. You may use the search function or open a proper thread for people to participate.

As far as I am aware, whatever you choose go for a high CRI emitter. Some compact flashlights come equipped with these kind of leds, like the Lumintop Tool and many others, but I guess their design is still quite different from what you call an intra-oral light. :???:

Cheers

Thanks for the links.

I ended up getting 10 of 12mm x 1mm N52 magnet from ebay:

http://www.ebay.com/itm/381760993198

Nothing to worry much BLightSam, but better choose thicker NdFeB magnets next time, they're quite brittle.

Cheers

1 mm was chosen out of reflex to avoid the problem of battery Too Long issue. The next batch will be 2 mm ![]()

Well I must admit that I am surprised at HKJ”s results regarding a neodymium magnets resistance.

I tried 4 Liitokala 26650”s both with magnets & solder blobs (the same 4 cells) in my S70 on turbo using a short piece of 12awg wire & a Uni-T-UT-210 clamp meter which I have found to be pretty accurate.

I definitely saw 0.4 somethings amps difference between the magnets & solder blobs.

I am not disputing HKJ”s results so either my magnets are higher resistance than the ones HKJ used or my testing was very inaccurate.

Either way because of my results I stopped using magnets & started solder blobbing instead which I think is a better & more secure way, so therefore less chance of potential problems, of turning flat top cells in to button tops.

It might be contact resistance.

Actual contact resistance shouldn't be dismissed; it can be low and insignificant, or be troublesome:

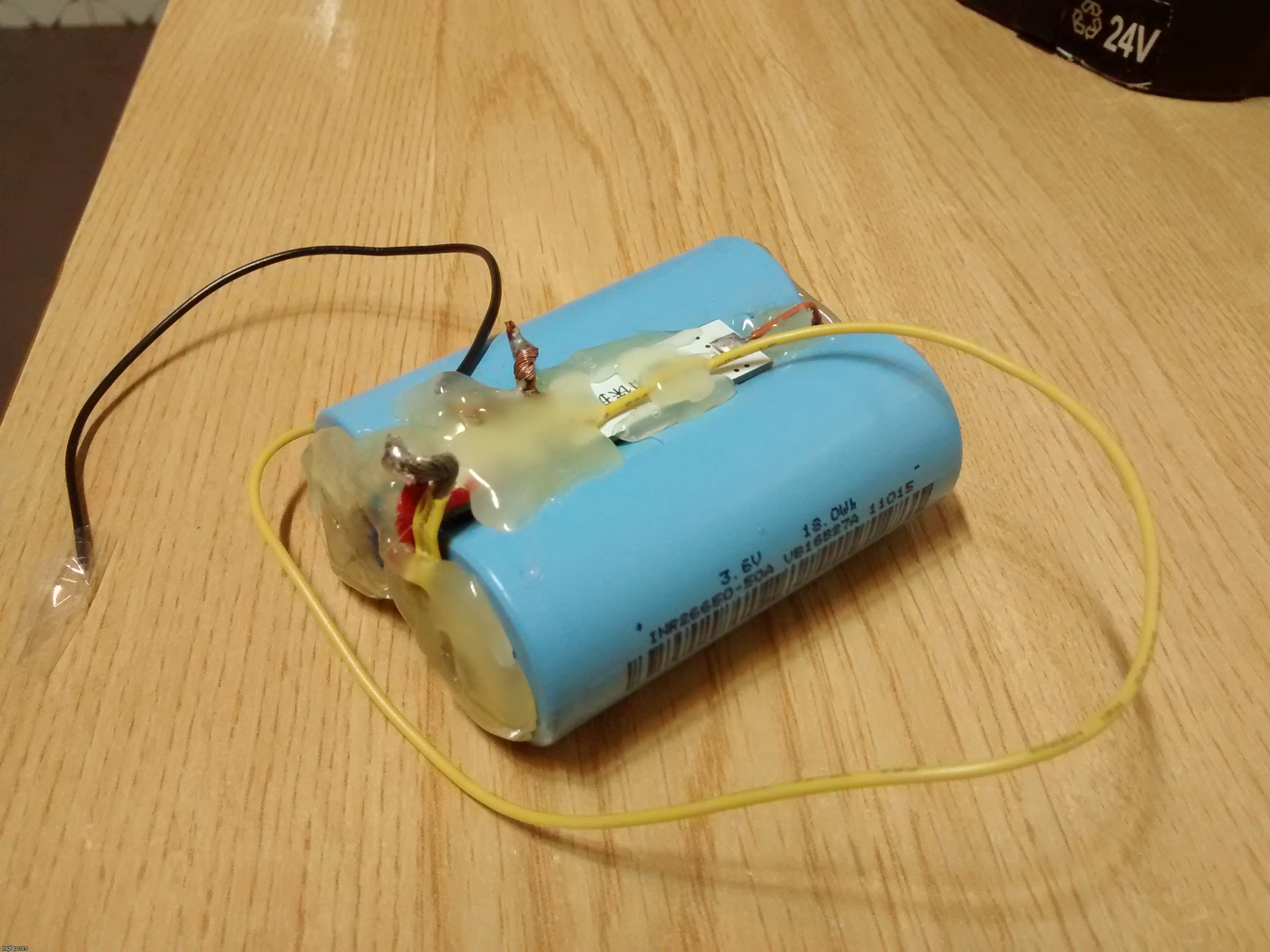

During the initial stage of this small drill's pack, batteries were connected with hot glued NdFeB magnets over thick multiple layers of aluminium foil. Soldering over the aluminium seemed good, but turned out to be a failure as I later discovered (stray resistances caused triggering the BMS low voltage cutoff).

After upgrading the BMS with a layer of additional MOSFETs, adding a well matched pair of TrustFire IMR14500 cells high drain “nitro” escorts and soldering the cells with Bi50Pb32Sn18, with this pack the drill started trouncing stuff with 10mm bits with ease.

The drill's owner reported a “funny toasty smell” coming out of the motor windings. LoL!  :facepalm:

:facepalm: ![]()

Cheers ^:)

Originally posted on Sun, 04/09/2017 - 12:02; info added.

I suppose it could well be a contact resistance issue although, cell anode/cathode were clean, magnets were clean & similar pressure was exerted on the cells & tail cap jumper wire when testing.

But now that I am comfortable with solder blobbing cells I won”t go back to magnets :+1:

Mmm, know what? How about (low temp) soldering the magnet over the cell's anode? If done carefully, should end up looking very professional. :STEVE:

Cheers ^:)