Have fun putting that together!

Wow nice.

My F30R got here today!

Nice. With a comment from Matt like he did this must be a challenge. To me it would be an impossibility.

checkbook is ready, not sure there is enough in it though :_(

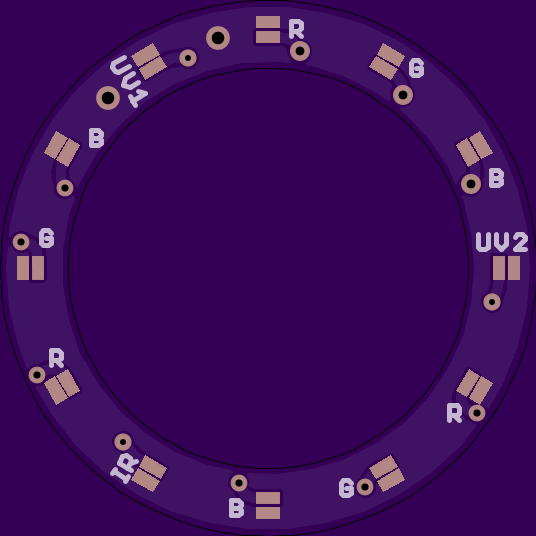

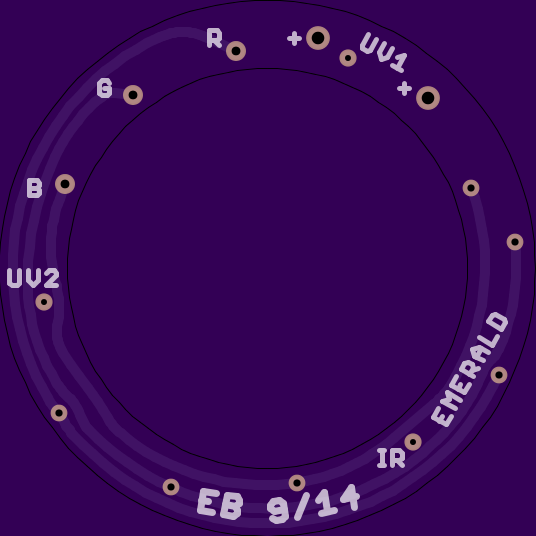

I spent a really long time looking at the ring of LEDs, trying to come up with some way to put TIRs or small reflectors in there and still get heatsinking and still make the light possible to assemble, and I couldn’t come up with anything. So I gave up on having nice beams and made this LED board that will fit right inside the aluminum ring with the 12 holes in it. The ring will provide heatsinking and keep assembly easy, and it has cone shapes machined in that will form very rudimentary reflectors. The beams will be very wide unfortunately, but they shouldn’t be ugly. There are 3 of each of the primary colors (spaced evenly so they won’t be off center) and single emitters for 380nm, 405nm, and 850nm. I used XQ-sized components for all so that they’d fit easily into the existing holes. Colors are XQ-E, UV are Lux UV, and the IR is an Osram SFH 4710 which appears to be almost the same package as the Lux UV

What if I turned a spacer to fill the gap between the bottom of this board and the pill / light engine housing then polished each individual “reflector” or better yet (tho expenses) had it electroplated?

Yeah I thought about something like a spacer for quite some time. In the end it seemed like it was more trouble than it’s worth:

-complicates assembly since you’d have to grease it down to the locking ring

-very tough to get the height just right because the locking ring is threaded in

-XQ parts are designed to heat sink to the top surface of the board

-not really an advantage for optics

Now polishing and/or reshaping the reflectors is probably something to pursue. There’s a pretty large vertical section before the conical section which should be removed. We could do it by milling forward from the back of the ring to move the PCB mounting surface towards the front of the light, but I think the best option would be to keep the depth and reshape the reflectors somehow. I have a weird dremel bit that’s a rounded cone shape that might work for that. Any ideas on drilling in reflector shapes?

Since you’re pretty ok with it not being an ideal beam what if you gave up the idea of individual “reflectors”, its going to be almost impossible to machine 12 of them perfectly even, even with a mill (which I have access to) but what if we cut the separation between the “reflectors” out with a ball mill, something high flute count so the finish came out really smoothly (like a 6 flute) so the “reflector” was a polished U-channel. After cutting it I could tumble polish them.

I’ll also look into EP’ing, I’m just guessing to do our two reflectors is going to be way to much $$, that leaves hand polishing or something I’ve never tried before, chrome powder coat.

What angles do all the emitters project?

Thinking about all the work to an unknown alloy, it might be easier just to turn a new “reflector” with the same idea (it could be done only on a lathe). Same size, same bottom but just turn a U groove into the top Scratch that, then you’d have to drill 12 holes and that’s take the mill anyway. I think the best bet it to either simply try to only polish / coat each of the unmodified cup’s, or to machine then into a single channel and polish that.

edit: What about the possibility of making, or having made a single round ring TIR? I wonder if there is a version if PMMA that would offer decent optical properties that could be 3D printed.

Actually I have a couple of those, but they don’t help here since we need a tiny optic to fit in the ~6mm space between housing and reflector

I was thinking about these, but they are 8mm.

Edit: Head OD looks to be <45mm, so the above wont work.

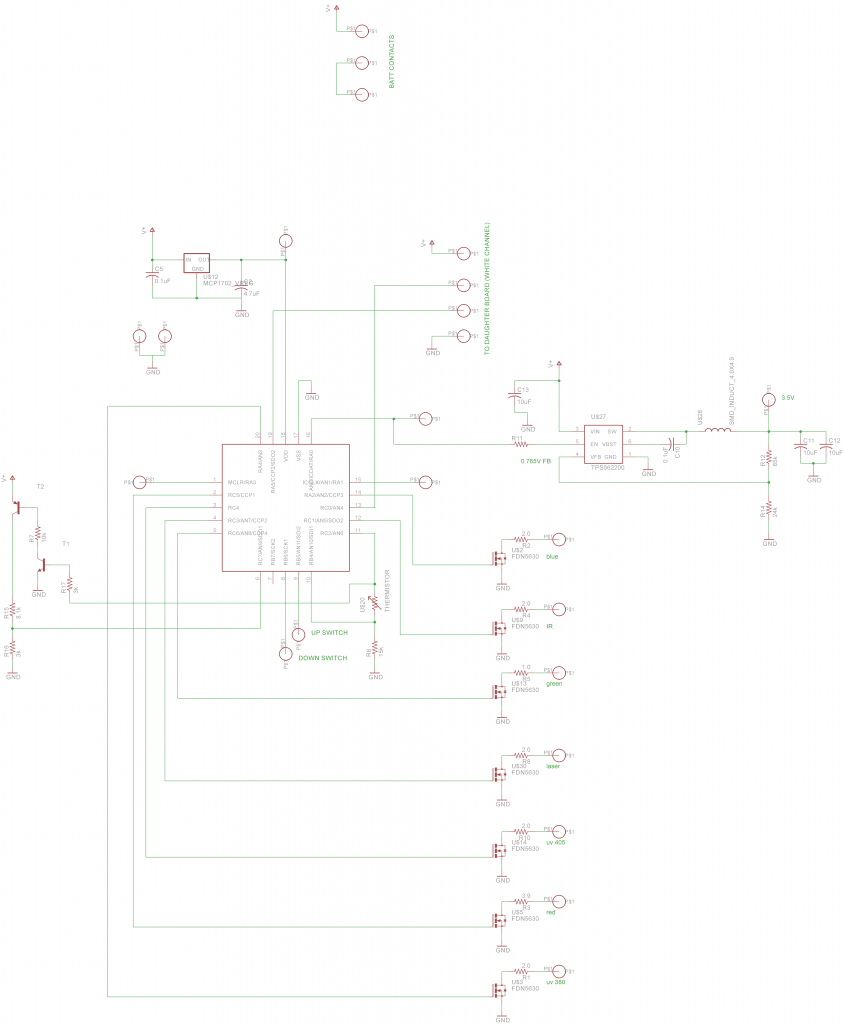

Ok I’ve been studying the .sch for 2 days now, I was going to ask this in email but I figure I’ll put it here for everyone…

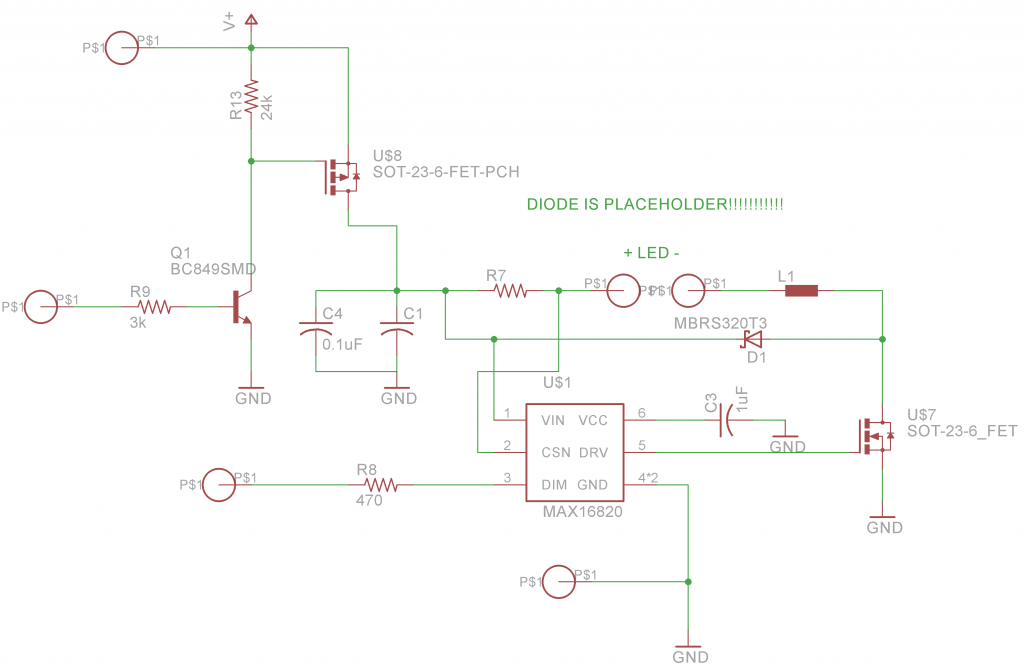

It’s the TPS562200 that does the bucking for the color / UV / IR emitters correct? And it looks like either R12 or R14 is the sense resistor for that (tho the values seem high for a sense resistor). So what if multiple emitters are on at the same time, they would get current split like if they were simply paralleled or the chip will increase current to compensate? What’s the max current?

The other question is about what’s going on with the FET and what I assume to be a BJT up top powering the MAXUM chip, this is obviously to shut it down cause of its standby current, what exactly does this circuit do tho? Specifically what does Q1 do (and R9 is just a gate resistor right)?

Right

these two form a voltage divider which sets the output voltage by making a 3.5v output produce a 0.765v level at the feedback pin, which is the setpoint the chip is regulating to. The chip has no specific output voltage, and in fact it doesn’t know or care what the real output is, it just regulates to 0.765v on the fb pin. The manufacturer does this so that the same chip can be used to produce any voltage you want.

You’re thinking of constant current regulators, but this is constant voltage for exactly this reason. The led currents are individually set by their resistors next to the FETs, so you can have any number on simultaneously and their currents won’t change. The regulator will supply whatever current it needs to in order to maintain 3.5V, so yes it will compensate automatically. The buck regulator is set at 3.5v because from this voltage I can easily set led currents with resistors while minimizing the wasted power because the voltage overhead is low.

It can supply up to 3A total for the color leds

Q1 is necessary to protect the microcontroller from high voltage and to allow the FET to completely shut off. If you connected directly to the FET gate, when you tried to turn it off by setting the uC pin high, the FET would still see (Vin - Vcc) which could be as high as 12.2-3.3= 9.3V, so it wouldn’t turn off. You could then try setting the uC pin to high impedance and let the FET gate pull-up resistor turn it off, but then your uC would see as much as 12.6V on the pin, which would waste current at best and destroy the microcontroller at worst.

R9 limits base current into the BJT. BJTs are current-controlled unlike FETs so you must regulate base current to keep from destroying them

Ok one more Q,

The 3A total to the colors, that’s limited by the TPS regulator or the FET’s?

That’s the regulator’s limit, I set the individual current limiting resistors so that total current draw can’t exceed that. I plan to set most of the colors around 700mA

Ok well looked up the datasheet and turns out I have a few more Q’s still…

It states 2A max, I’m assuming you’ve used this chip before and already know it can do 3A? You must be using the TPS563200?

What’s the reason for having the sets of 2 parallel cap’s (C11/C12 & C13/C14) instead of just one at each location? To keep them from getting saturated? Also I notice you’re using quite a bit less total capacitance on each of the pin’s. I believe I remember you saying this is the exact chip you use on your MELD driver, so I assume your way works fine, why the difference from spec?

Actually you’re right, I had 3A in my head but I’m using the lower power version. The firmware only allows ~1.4A maximum at one time with all colors set at 700mA so it won’t be an issue.

You’re right that the amount is low, I generally just put the 0603 package on there and then fit as much capacitance as I can. I’ll probably get more than 20uF total on the actual board. The reason to have multiple caps is to layer them for better filtering—a 10uF in parallel with a 0.1uF will filter out high frequency crap much better than a single 10.1 cap. The reasons for this get into much more science than we should include here I think…

Here’s the final version of the schematic with a few updates:

So today I’m looking at the voltage regulator for the MCU and I see it’s polarity protected which effectively protects the MCU, are any other components susceptible to batteries being inserted (regardless if any one, two or three are inserted) wrong?

I’m not sure how the TPS562200 or the MAX16820 would handle reverse voltage. Both would be fully exposed to it if the batteries were put in backwards.

Mixing up the directions is another matter—you’d be applying reverse voltage to one of the cells which could get dangerous.

I have polarity markings and springs/contact plates which both differentiate the cell direction, I’m not too worried about them getting mixed up.