I promise this will be the last new build for the year. Having a conversation the other day with a member here it was decided one more light had to be built. All Blame goes to member ________r who may pop his head up at the appropriate time. If he doesn't I will dob him in anyway. As we speak this light is on board with Santa heading north to its new home. Well not quite but will be tomorrow. Its Sunday here.

There's not a lot new in this light. I just haven't built one like it. I have another light similar to this one with an XML in it driven at the same level so will take some beam shots tonight if possible for a comparison.

Firstly I'd like to show you my new parts tray. I wonder if the person that gave it to me recognises it? Its a biscuit tray and is the second light I've used it for storing it's components.

Firstly is the bezel. This holds the TIR in which is a press fit into the head.

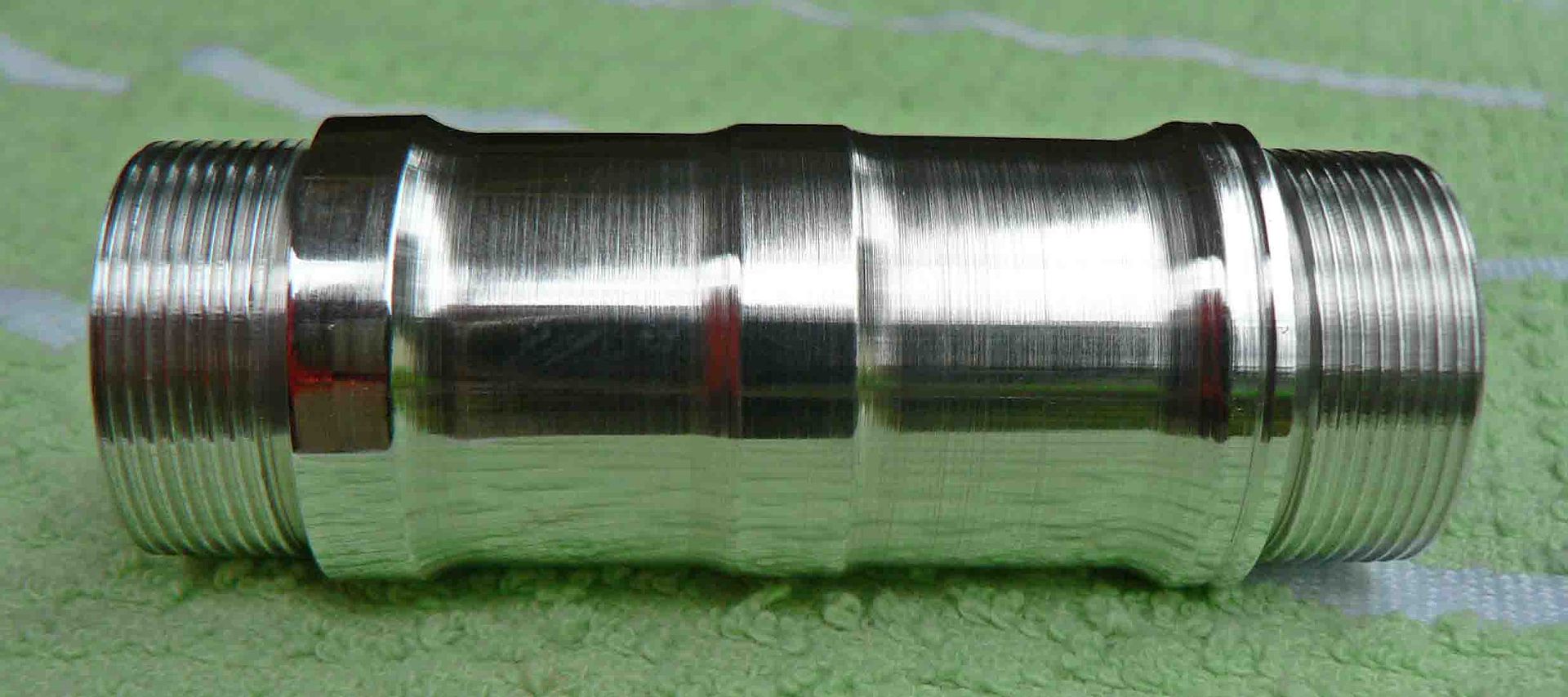

The battery tube has been machined out in the centre for gripping with the second and third fingers during normal operation.

The tailcap has three anti roll drive screws which are yet to be fitted and drilled for a lanyard if one is to be fitted.

The head has small tiny fins that may but probably will do nothing for cooling. On high this light will get hot. The right picture is the TIR end.

The pill is the usual 20mm threaded one I use being 12mm long. LED is a cool white XPG-2 on a copper Sinkpad driven by a 3 mode 7135 driver at 3 amps on high. This leaves the XML driven at the same current and identical TIR for dead on the light meter. The driver is soldered into a FT driver adapter and then pressed into the pill.

Most of the parts in this light. The drive pins are missing.

The assembled light. Unfortunately I have not worked out how to seal this type of TIR so dirt and water may be susceptible to getting inside.

And finally a shot with a SolarForce L2M.

To everyone here thanks for another year of fun and games along with a serious amount of learning from you all. Without this I would certainly not be building lights.

Have a happy Xmas and new year. Again, I will not bore you all with another light build this year.