Would like to start reflowing LED’s. I have a soldering station with s heat gun. What’s a good temperature to start with? Any tricks or techniques you guys use?

I hold the MCPCB in a “helping hands” and use the hot air from underneath at 200 - 250°C with 100% air.

If you have a heat probe, I would suggest heating it to get a feel for the way the heat flows from the wand. If you have some old PCB laying around, you could practice removing SMD components with it too.

I use a jet lighter and a pair of tweezers that I stole from my girlfriend for reflowing my LEDs. You don’t have to be too precise with placing the emitter on the PCB; the surface tension of the liquefied solder will “suck” the emitter into place. As ouchyfoot mentioned, helping hands would be a great idea, but if you don’t have any, some old alligator clips and duct tape will work in a pinch. Also, don’t be too afraid of overheating the emitter, as they can usually take a surprising amount of abuse before failing.

I reflowed one in a stainless fryingpan on the stove, but Old Lumens has a youtube channel showing how he reflows (amongst a bunch of other things!!!), very simple

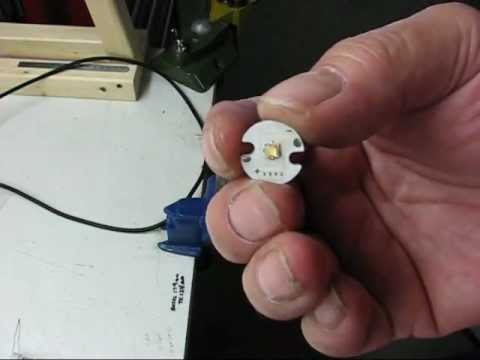

I use this method also and it works every time. I place small amounts of soldering paste, stick emiter/s heat it up from underneath with a jet lighter and when the solder is nice and shiny I stop ![]()

This was done like that:

i have gas oven and small frying pan, i have no clue what temp is needed, i just wait untill solder paste melts, make sure led is centered, and shut off the gas, i use low flames small burner, reflowed about 100 leds, no problem,

I have seen some people place pub on a steel plate and heat it up. Thought maybe that would help dissipate the heat better. Anyone try that?

Having a heat gun gives you a leg up already. Practice on a blank star. You want to get it just hot enough for the solder to start melting. But you don’t have to be super precise temperature wise. LED’s can take some abuse.

-Does solder stick aluminum ?

-Is flux necessary or can you just use a soldering paste?

no it does not.

do not use flux, soldering paste has that already, use paste only

I put the star in a wooden clothespin and then put the clothespin in my small desk vise.

Then I just hold my 20-year-old cheapie Radio Shack 40-watt soldering iron to the bottom till the solder melts with my left hand, while my right moves the tweezers.

When I’m done I give the bottom a few swipes with a file to take off any solder that may have come from the tip of the iron to the bottom of the star.

I like to tin the +\ wire pads or put solder paste on them. When you see them melting, you know your LED is done. Sometimes it’s hard to tell by just staring at the LED.

I do it on our glass cook top, preheat it at 6 (of 10) for about 60 sec, turn it down to 4 then slide the star over onto the burner, watch for it to flow then slide it off. After that I grab it with a pair of needle nose as fast as I can and move it to a 1/4” thick sterling silver plate I have to suck the rest of the heat out of it. I can pick it up with my fingers within 15 seconds of it hitting the silver.

I also do the resistor side of my BLF15/17DD’s and tiny10’s on the stove.

I’ve started using solder paste and either a needle or a stencil (it makes things much easier) as the application device. Then I apply the LED with tweezers over the area and give it a good push down. Then it goes on to the helping hands. I set my heat iron to 350 C (which is a little on the high side) but I run the fan at a pretty low speed and I keep the nozzle moving over the MPCB. Once the paste melts and the LED seats properly, I remove it from the helping hands and put it on a block of copper I keep on a shelf to quickly suck the heat out of the MPCB.

I’ve reflowed several dozen LEDs in this style, and not one has failed me yet. Not to say I haven’t destroyed LEDs before, but none from the reflowing process I use!!