After reading Djozz' testing of the new 3rd Gen Oslon, I was interested in the throw potential, as it looked like they might edge out the XP-G2 S4, if able to be de-domed successfully.

Here's the BLUF;

- Difficult to de-dome cleanly.

- Smaller footprint than XP-G; issues with centering rings.

- Not suited to high-drain cells + FET driver (over current).

- Couldn't edge out the XP-G2.

Here's the long version;

I ordered the minimum amount of 5 from RS online, & they arrived during the week. I was able to spend the day destroying testing them yesterday....

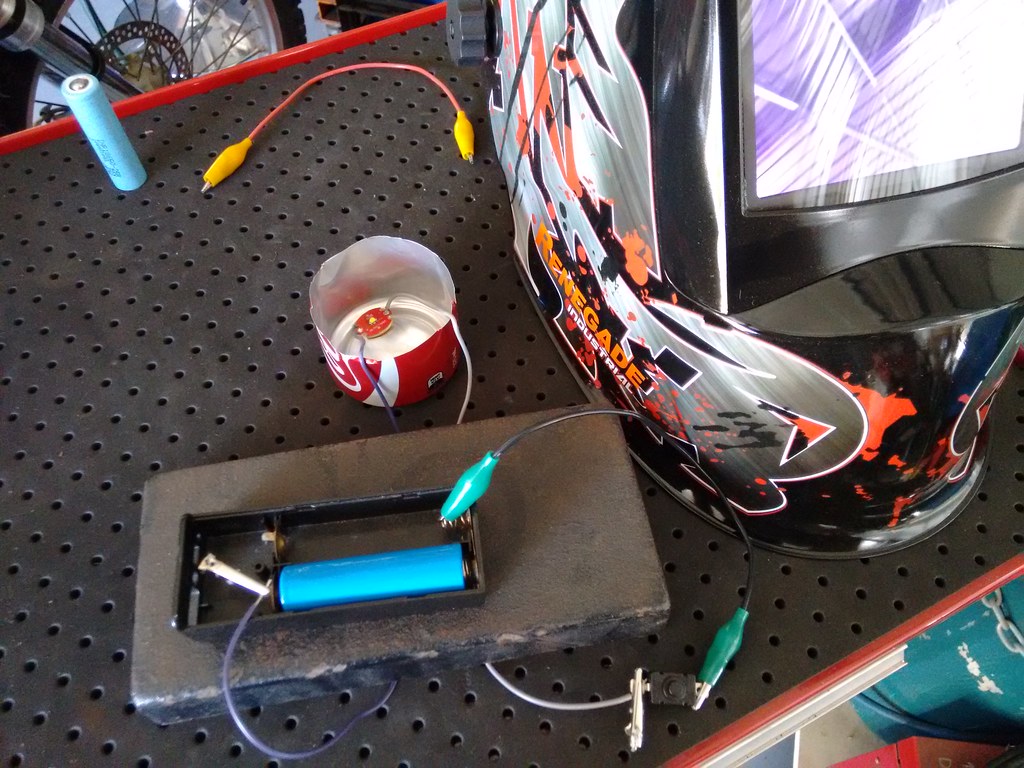

I used a Courui D01, (stock reflector & lens, fully modded internals, ATtiny 85v Fet driver) for the test mule. Cells were 25r's.

First test, as a base-line, & for first impressions, was with the domed emitter;

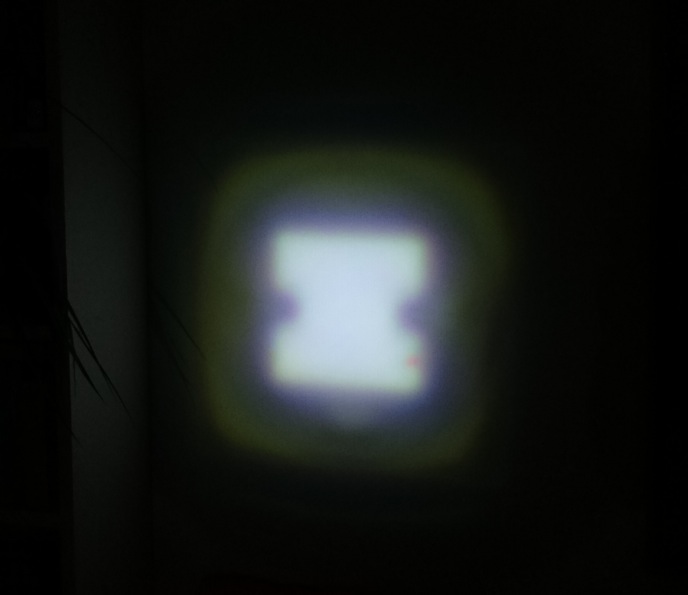

Beam pattern was unusual, due to the placement of the bond wires in the middle, & there was a purple & yellow hue noticeable around the outside of the hot-spot, on a low output mode.

I measured throw at 180KCd, without any fine tuning of focus. Not too bad.

I was also loosing some output due to high current draw; Taken at the emitter with clamp meter, it was drawing 8.05 Amps, after taking the throw reading.

Referencing DJozz' graph, it was about 1 Amp too much for peak output.

Next test was a sliced dome;

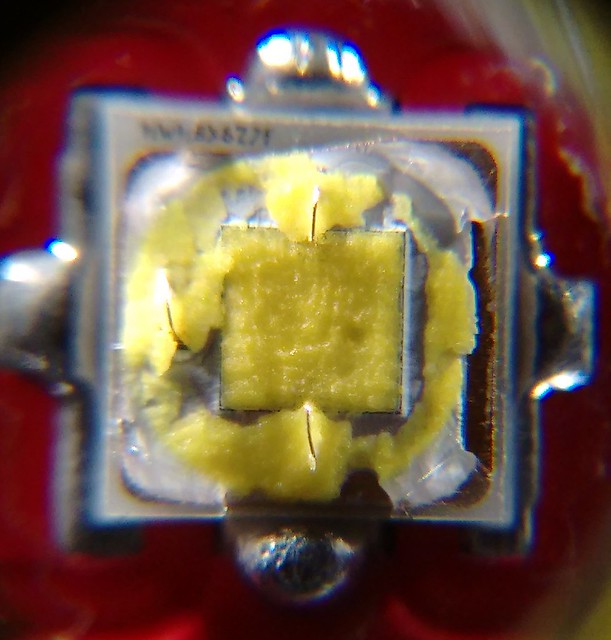

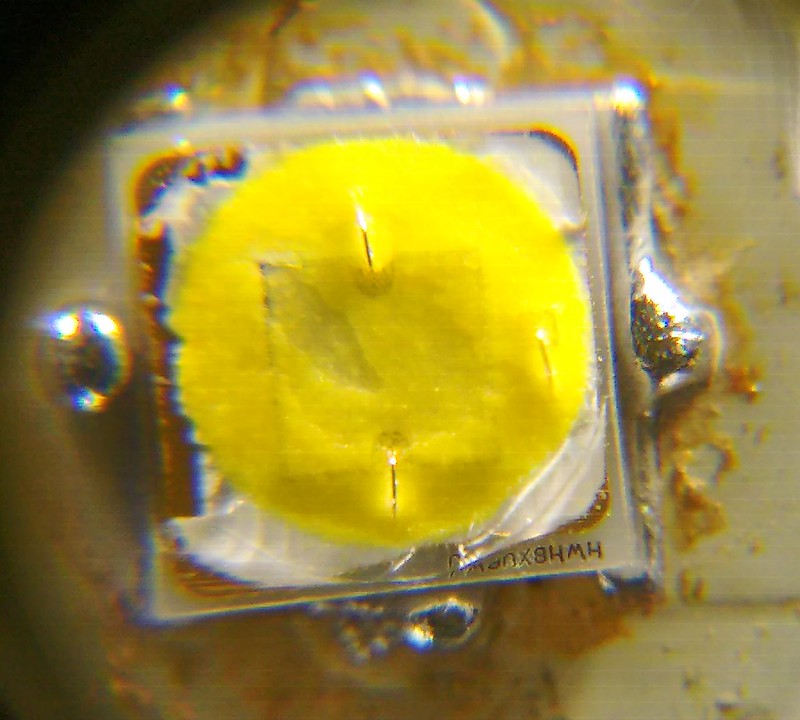

I used a steel washer that was .032" thick as a guide to cut the dome off. The dome seemed easy to cut, & it was looking nice & smooth. I figured that I could go a little lower, so went for another cut, this time using a .024" washer.

Oops, too much; cut off the bond wires. One LED down, four to go.

I flowed on a new LED, & repeated the cut with the .032" washer. Once again, it cut very easy & cleanly.

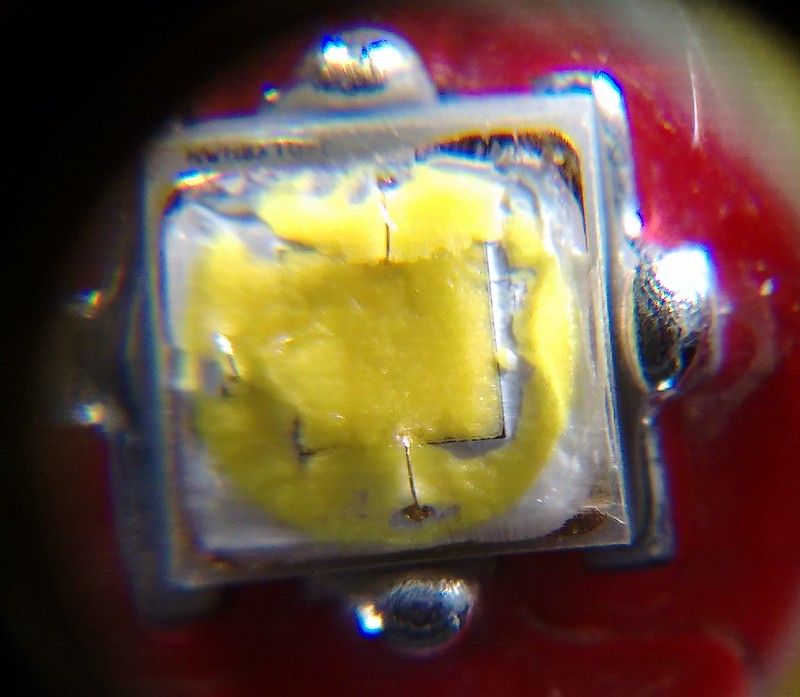

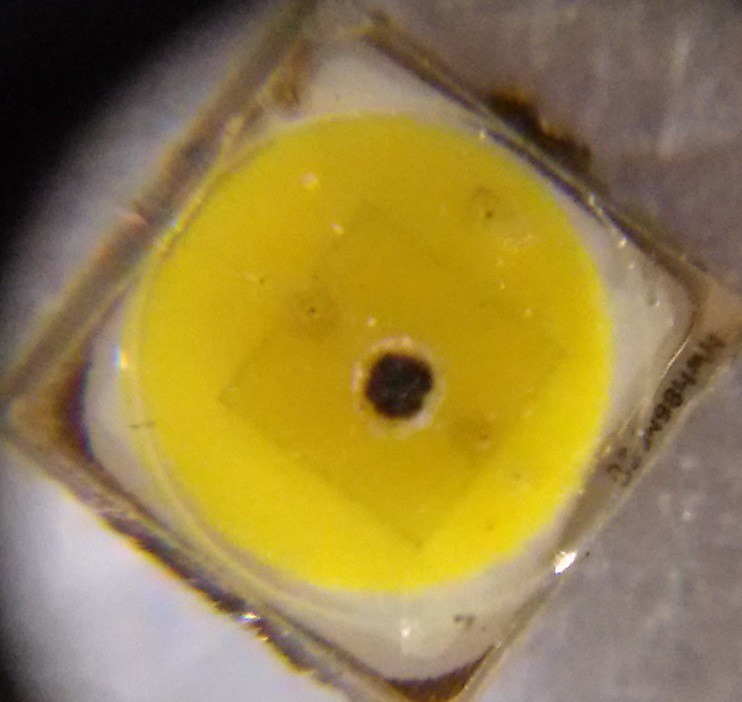

I installed it into the light, & it looked very promising. I cycled through the modes a few times, & was about to go into the shed to take a throw reading, when I saw a burn mark in the center of the LED. I tried shaving it a little more, but the burn was right through to the die.

Damn it - I don't know if it there was something on there that heated up, or if it burnt its self up.

Two down, three to go...

During the above testing, I had two other LED's soaking - one in the tried-n-true petrol, the other in some "Goof Off".

I had never tried the Goof Off, but spotted a small container of it in the hardware store, & remembered other members having good success with it. I noticed it was about 50% Acetone, & there was some 100% Acetone right next to it on the shelf, so I grabbed that as well.

Well, after about 4 hours, the Goof Off had done absolutely nothing, so I swapped it over into the 100% acetone.

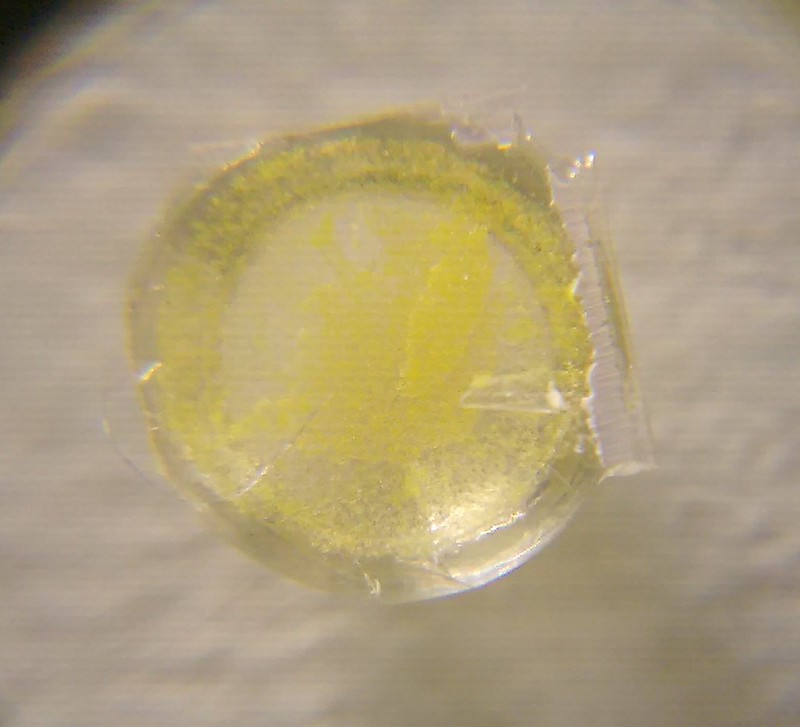

Meanwhile, the petrol was showing signs of promise, with a swollen dome, & on closer inspection, it appeared to be separating slightly on one edge.

A couple more hours, & the Acetone had not worked any better, so I cut a few slits in the dome to try & spur it on. Meanwhile, the petrol had swollen some more, & the separation was more obvious.

Another hour later, & the Acetone had fared no better. I tried flicking the dome off, but broke a bond wire in the process. Three down, two left....

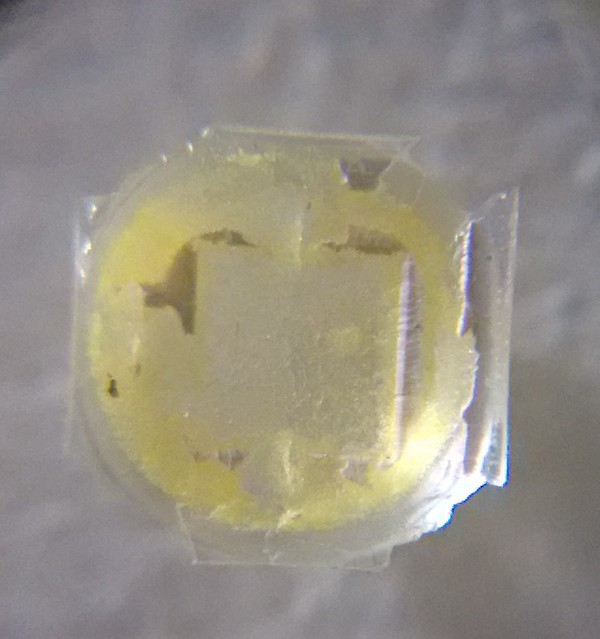

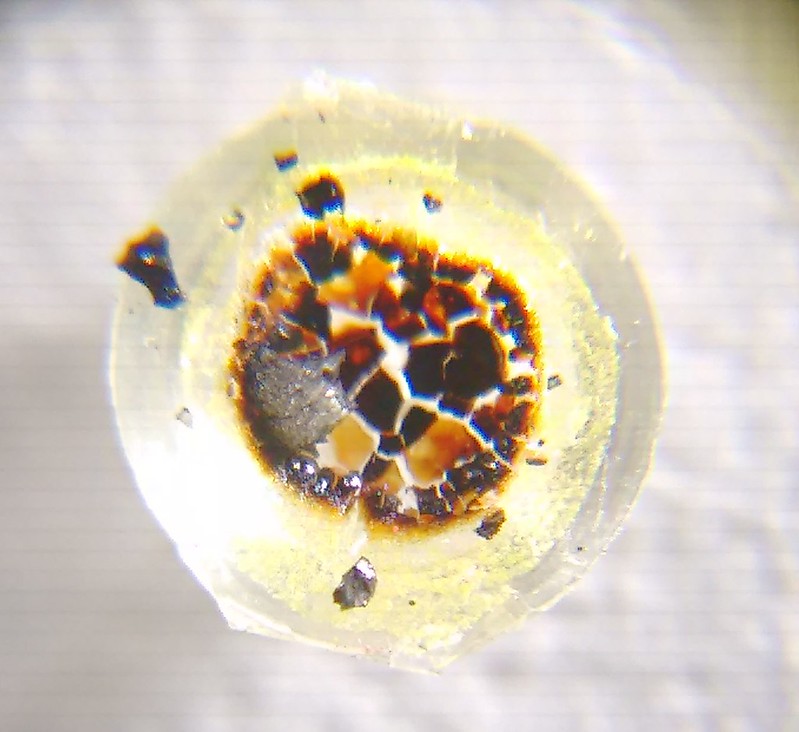

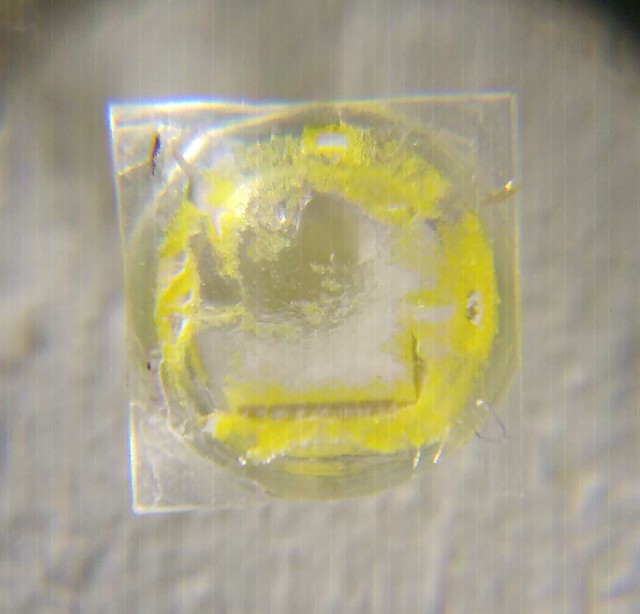

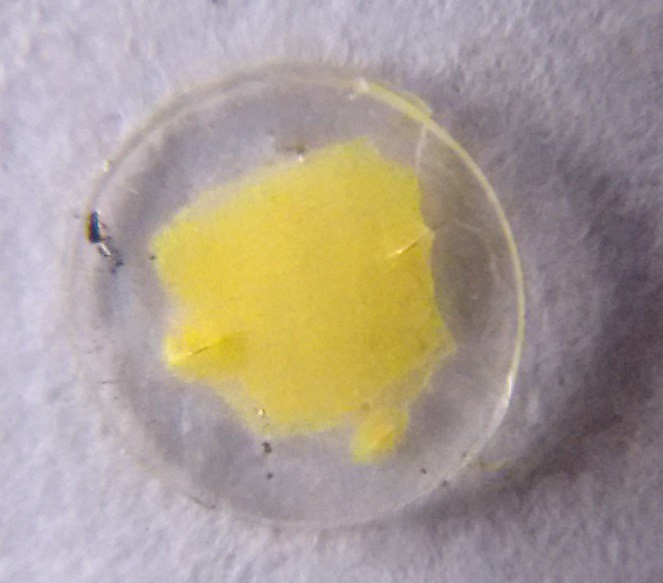

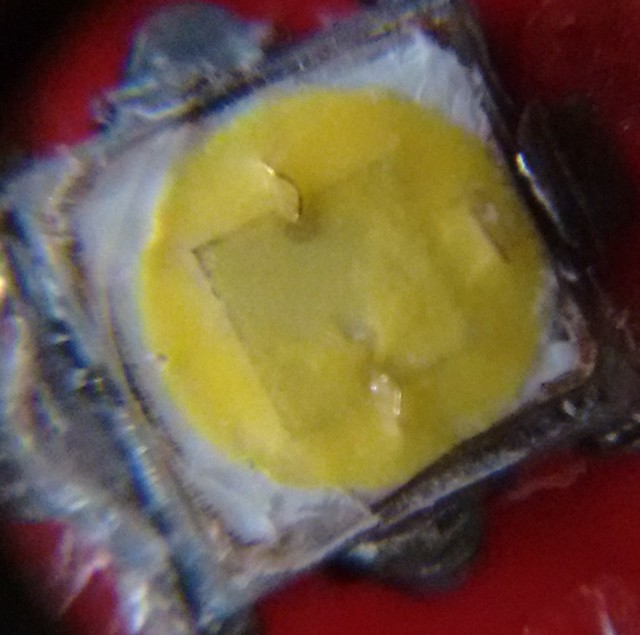

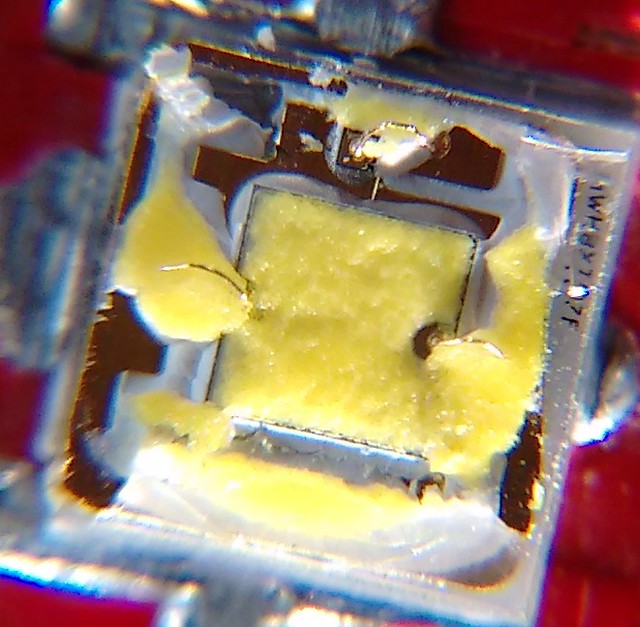

The petrol dome was looking promising, so I worked the dome off from where it had separated slightly.

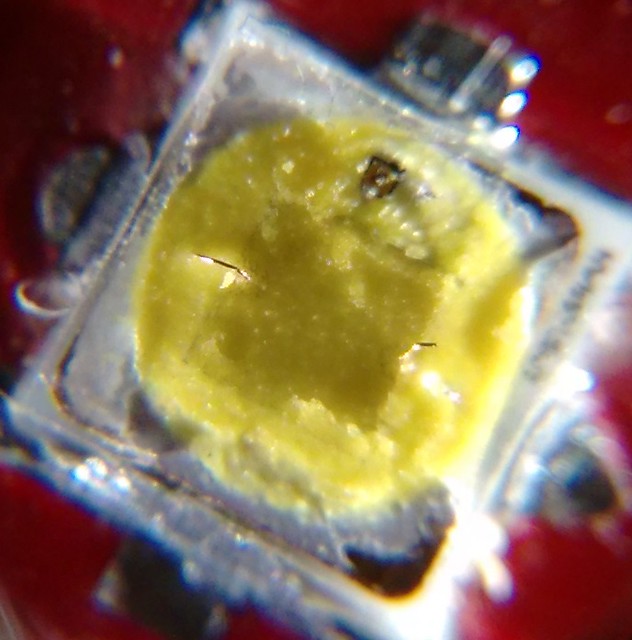

Not too bad, most of the phosphor had remained in tact, & no broken wires.

I decided that I would put the last untouched emitter in petrol over night, & give it a start by cutting around the circumference of the dome, in the same place that the first petrol LED had separated.

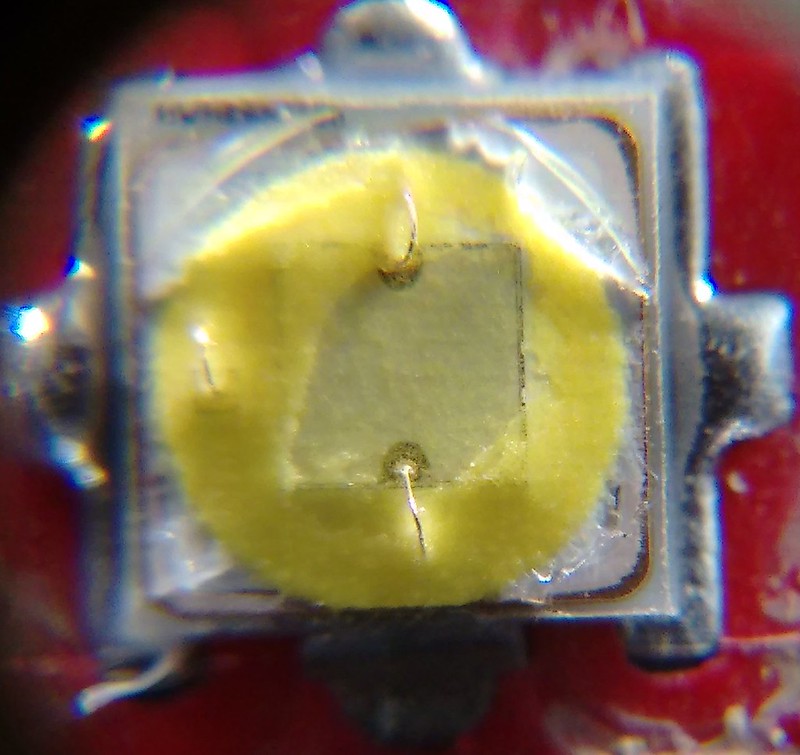

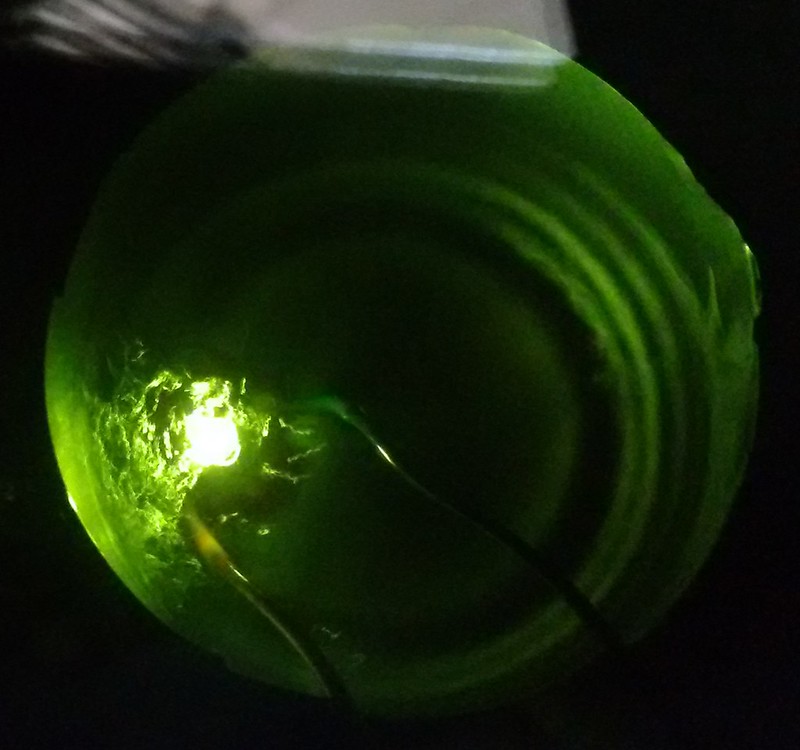

Right - now that I had an emitter to test, I installed it into the light. Initially, I measured 359KCd, without focus tuning, & with cells still a little too high.

After several focus adjustments, I was able to get a best of 398KCd.

By this time the cells were down enough for the emitter to be in it's peak range. I confirmed this after the test by taking a current measurement at the emitter; 7.25Amps.

Not bad at all, but with the same setup, I have measured 440KCd with the XP-G2.

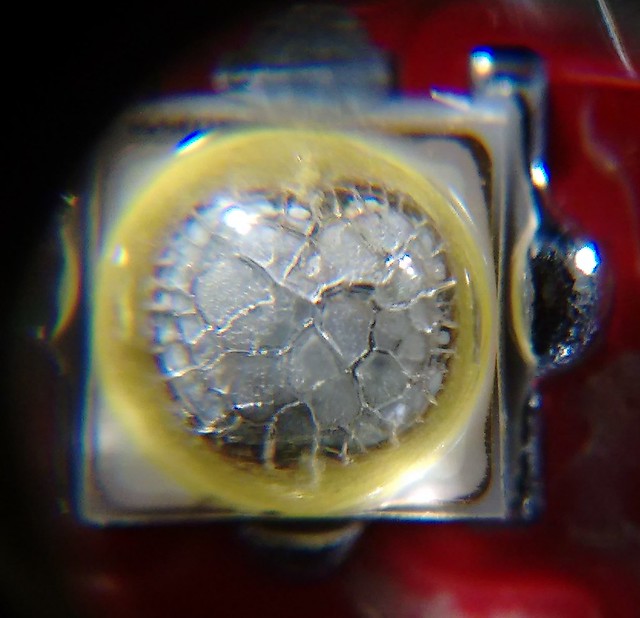

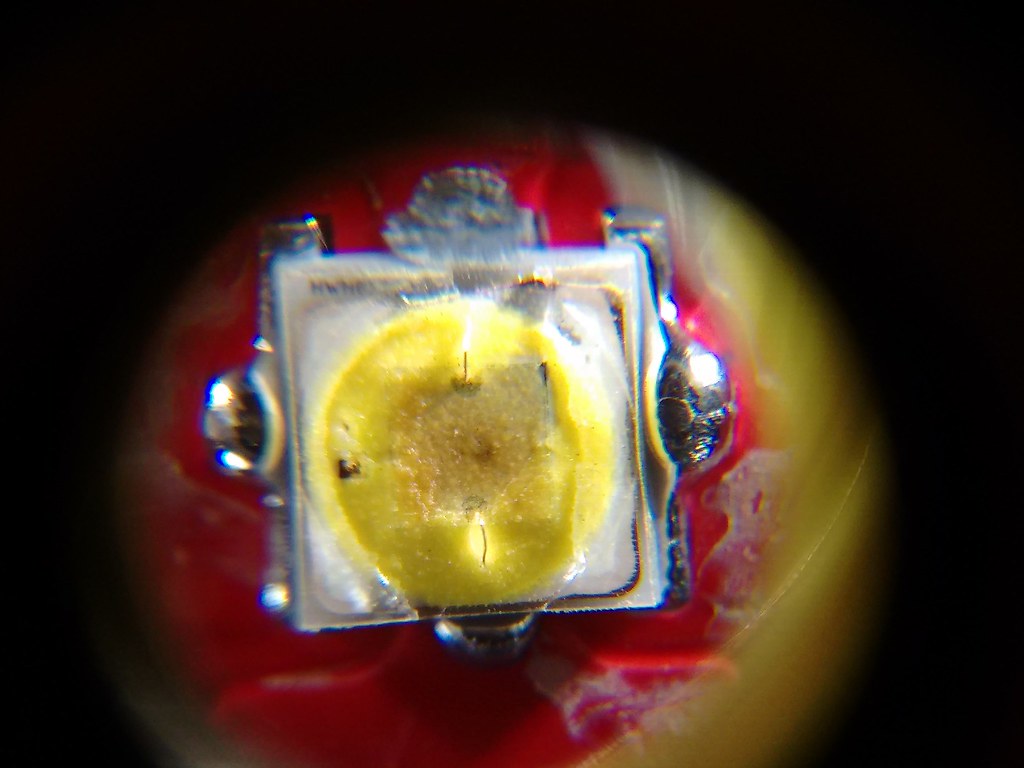

An observation I made whilst adjusting the focus, was that the positioning of the bond wires is presenting the reflector with two dull spots right in the middle of the die, either side of the focal point. I think that if the bond wires were in the same position as the XP-G2, or absent like the Nichia's, then it may have made the difference, as far as a reflector is concerned.

Looking at the white-wall on a lower mode, it looks like the bond wire location is impacting the uniformity of the beam. The purple is due to some missing/thin phosphor, but the bond wires are at 11 o'clock / 5 o'clock. My photo is not the best, but DJozz' photo (on right) using aspheric lens makes it more obvious.

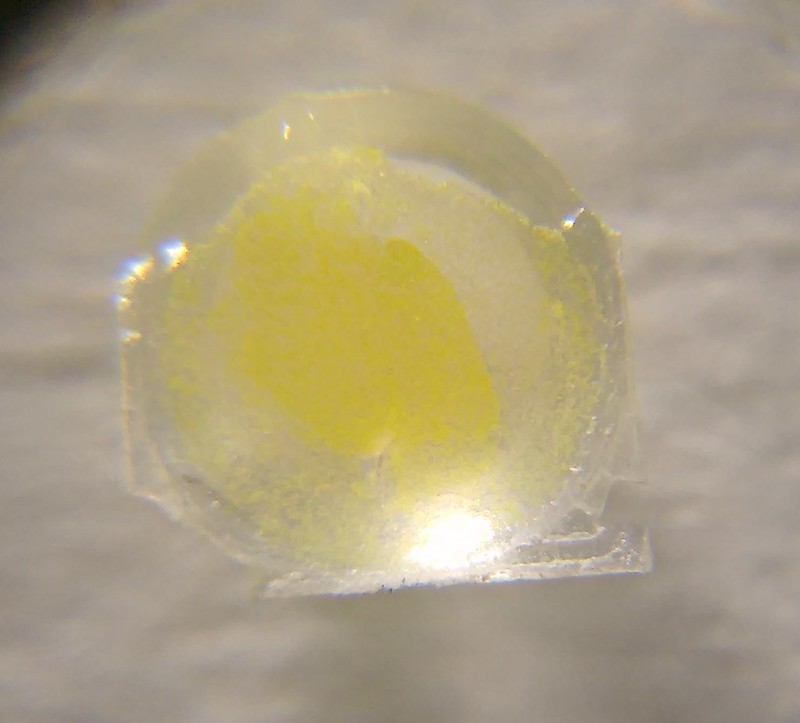

Now, how about that last LED? It's been in the petrol for ~12 hours now...

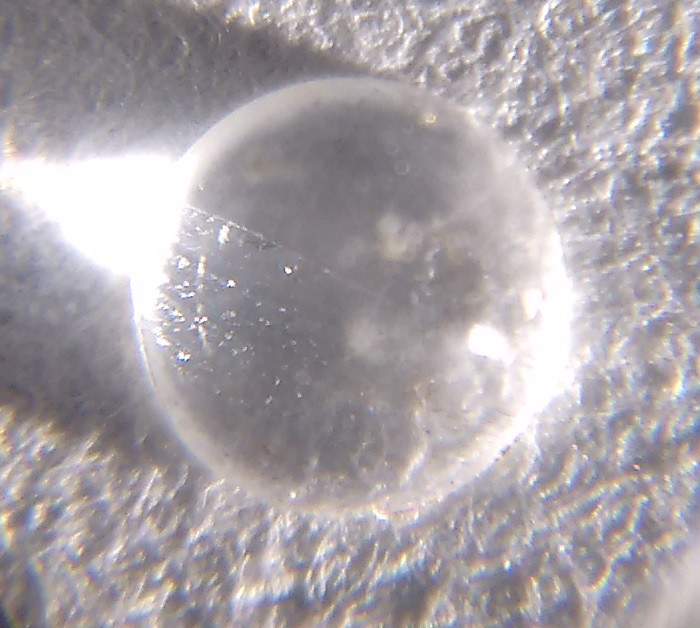

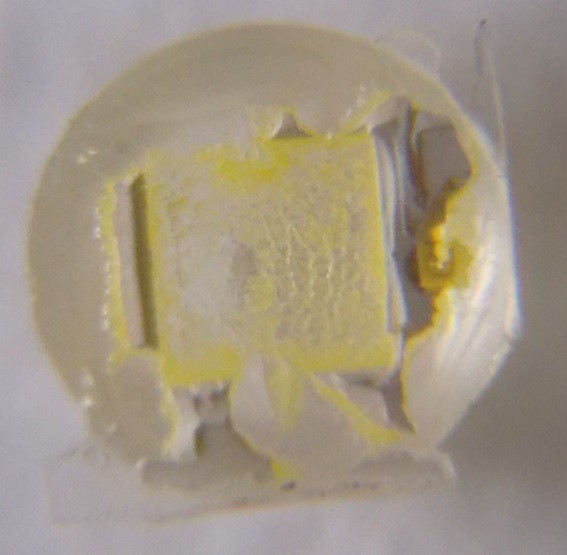

Sadly, the dome was still on, but was swelled noticeably. I tried to coax it off;

It looked ugly, & still took too much coaxing to come off. Unfortunately, one of the wires must have been damaged, as it blew when I installed it....

So, what to do with the one remaining LED? I think it would be best suited to a single cell light, with a regulated driver, or FET driver with a high capacity, low-drain cell.

Thanks for sharing the pain! :beer: