AMC7135 chips are current limiters. Each one allows 350mA. Thus, if you have 3, your LED will be given 1050mA.

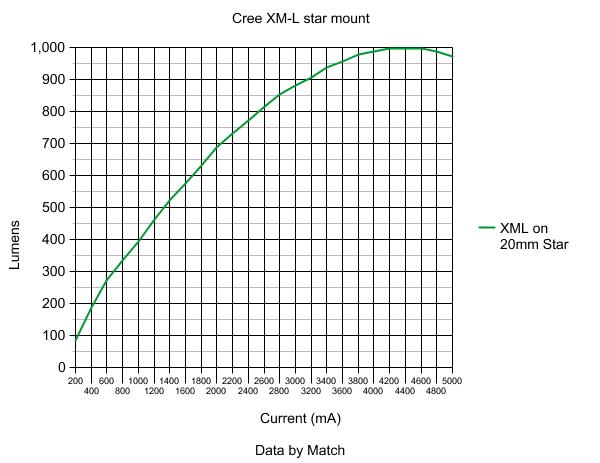

To see how this relates to brightness, you can approximate by using this graph:

For more information, visit this link:

AMC7135 chips are current limiters. Each one allows 350mA. Thus, if you have 3, your LED will be given 1050mA.

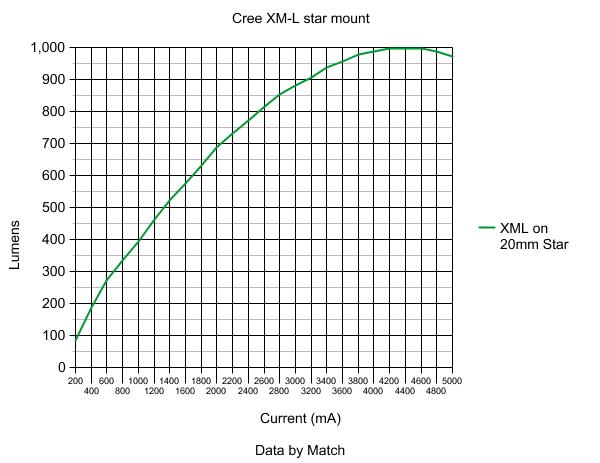

To see how this relates to brightness, you can approximate by using this graph:

For more information, visit this link: