No idea whether the 20mm is okay, only know by a test. If it’s a new driver batch then it most likely is the same.

Hi! Which heats up more, GT FC40 2.5A 12V or XHP70.3 HI R9050 5A 6V?

Simon do you have any TIR’s that fit the T3?

I’m interested in getting one but I would like to have it with a 10 degree TIR.

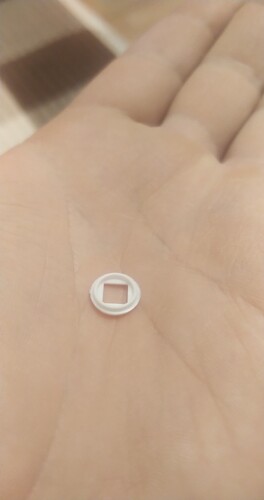

The S2+ TIRs have a ring of protrusion that does not contribute optically; sanding that down reduces the diameter and makes it fit a T3. That’s the setup I have on my T3.

Thanks, I already have some of those for my S2+'s.

The 5050 TIR have that, I haven’t seen that on the 3535 TIR I have.

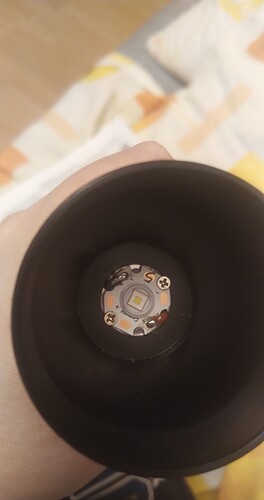

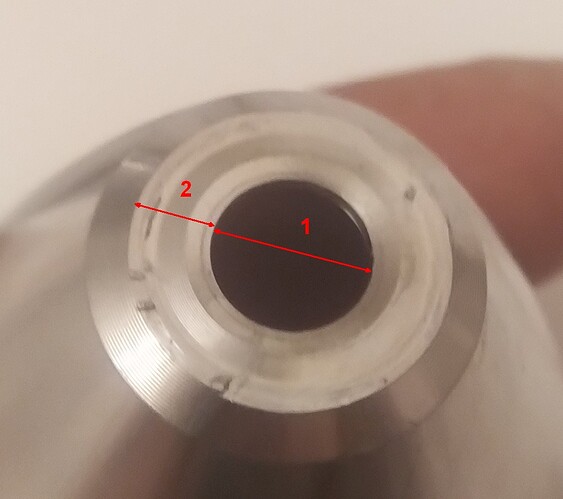

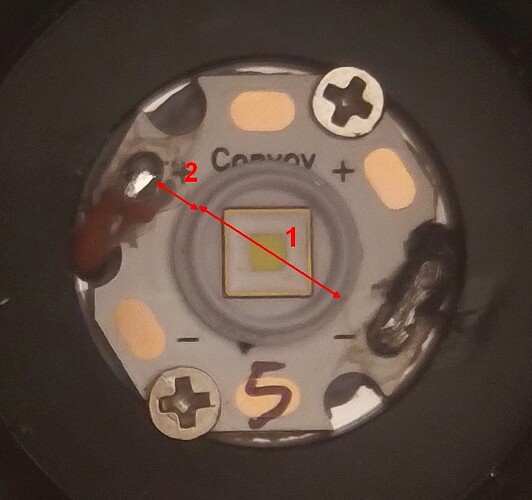

I recently received a L21B STF-40 5000K, ordered it on AliExpress. When using it in the evening on the street, I noticed that the glass was fogged from the inside. I decided to check if the bezel is well clamped. The bezel was not fully clamped, turned about 1/6 turn. I unscrewed the bezel back a few turns and let the flashlight lie for 2 hours so that the moisture evaporated. Then he twisted the bezel to the end. But now the flashlight stopped shining and intermittently there was a buzzing and squeaking. The bezel turned 1 turn, the light appeared. When clamped back to the end, the light goes out, and when unscrewed, it begins to shine. It turns out that the reflector inside is short on the body. I took it apart and saw this, I attach a photo.

And that’s what they answered me on the forum.fonarevka .

*I thought there was some minor flaw/soldering/assembly jamb - but no, it shouldn’t work in principle *

Compare how much distance in the lantern is allocated to the sides of the reflector - and how much larger they are at the reflector itself, it basically cannot fit there purely geometrically… Well, yes, the reflector just did not reach its place and rested against the wires. Tightening (and trying to put it in place) - you, of course, pushed through to the soldering points, and perhaps additionally removed the insulation… Probably, the black marks on the reflector just show where he scratched there and then shortened…

*You can, of course, cover all this horror with duct tape and rest against it so as not to shorten it - but you will not get into focus, and it will leak, well, in general… You can’t do that. *

This reflector is simply not designed to be installed in this flashlight.

The drivers are the same power, but the FC40 is not very efficient, it should heat up faster than XHP70.3HI.

Перепаять светодиод, края отражателя подточить надфелем, видно что немного не хватает.

Resolder the LED, sharpen the edges of the reflector with a needle, you can see that it’s a little missing.

All of mine have it, 5050 and 3535.

So I just thought about it some more.

I was thinking about the protrusion on the bottom of the 5050 and reducing the height.

I forgot that the T2/T3 reflector was narrower and y’all are talking about reducing the width.

That’s it.

I’ve never dealt with a soldering iron, so it’s unrealistic for me personally. You need to contact specialists. I’m sure this is a trivial job for many, but not in my case. You can sharpen the reflector with a file, but you will have to tinker with enough time. It turns out that it is necessary to change the very shape of the processing in production (unless these are isolated cases with errors in geometry and thickness). The landing diameter of the bottom of the reflector should be much narrower (or have a towering step along the edge of the hole for the LED) and have sharper angles so as not to touch or damage the wires. This is my opinion, and that of some lamplighters (who are much more competent in terms of installing lanterns than I am). A very unpleasant situation turned out in the end.

Круто я попал, короче.

Agreed. ![]()

Grinding/filing down the reflector would certainly resolve the issue, but strange that it was assembled that way in the first place. And good luck trying to keep that big reflector clean if you did. Certainly not a trivial job.

Not only is the reflector resting on the wires dangerous, it could also cause an issue with the beam since it’s not fully seated on the spacer.

It looks like the black wire is floating on top of the solder blob, instead of being inside it. This adds extra height to the solder joint which is making it touch the reflector. Maybe redo that joint?

17mm 6V 4A and 6V 5A boost

there will be a new model ,T5 , the tir is installed by default

It is more likely that the tin between the led and the mcpcb is broken.

I decided to completely disassemble the head. There are electronics engineers at my place of work, I will take them to them for soldering. The white plastic spacer is intact, but thin. The bottom of the reflector touches the wires. And when the bezel is fully tightened, damage occurs. So I can judge based on what I saw and what happened in my case.

The Sofirn SP40a TIR can be used in the T3, it’s an 8 degree TIR so, close enough, but it needs to be sanded to reduce the diameter a little bit (small lip around the perimeter of the lens, can be sanded or cut completely). It seems to be a little shallower than the T3 reflector so a thicker glass lens or thicker o-ring might be needed.