Looking good!

Bucket , This is a very interesting thread .

A lot of hard work here . Thanks for sharing .

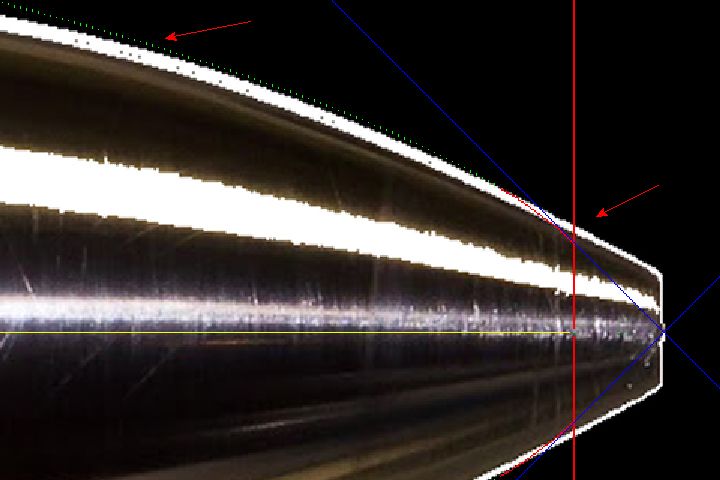

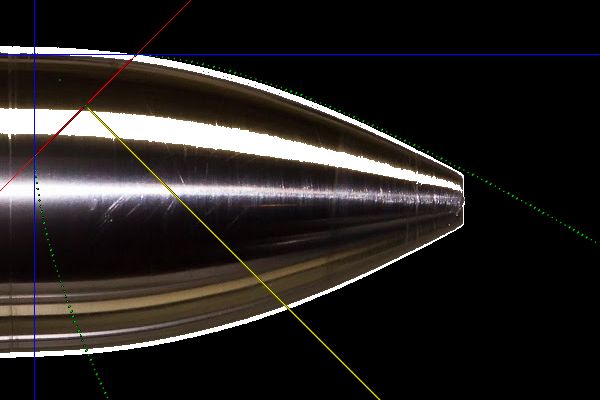

All your parabolas have the same basic bullet-shape contour that seems to be backwards. I can see you took great care to follow the coordinates precisely on this last one but a true parabola only lines up when mirrored and angled 45*. I don’t think it’s a coincidence and I can’t shake the idea that something is missing or needs to be added to the equation.

Doesn’t follow a parabola’s contour and where it doe’s is just a short section.

Follows the contour accurately for the whole length.

I know what’s wrong. Your feed rate for the axis going across is correct because it’s a fixed amount but the exponential depth rate for the axis into the material is reversed! Fix it and you’ll have your Parabola. :bigsmile:

I think I know what you are saying. I need to start from 0 on the rotating axis and work my way out with the cutter?

Also, do you ever sleep?

I also see what he’s saying, and I think he may be spot on!

Very adept to find the curve fitting in the wrong perspective. Nice.

I was seeing that the curve flattened out in the wrong place, but don’t know enough about this stuff to call it. Nice catch lightme!

Buck, you sure are getting the practice on parabolas! I like em all, but then again… perfection is ever elusive. Figure out how to apply what lightme just showed, and you’ll be making whatever reflector you desire, and perfectly! ![]()

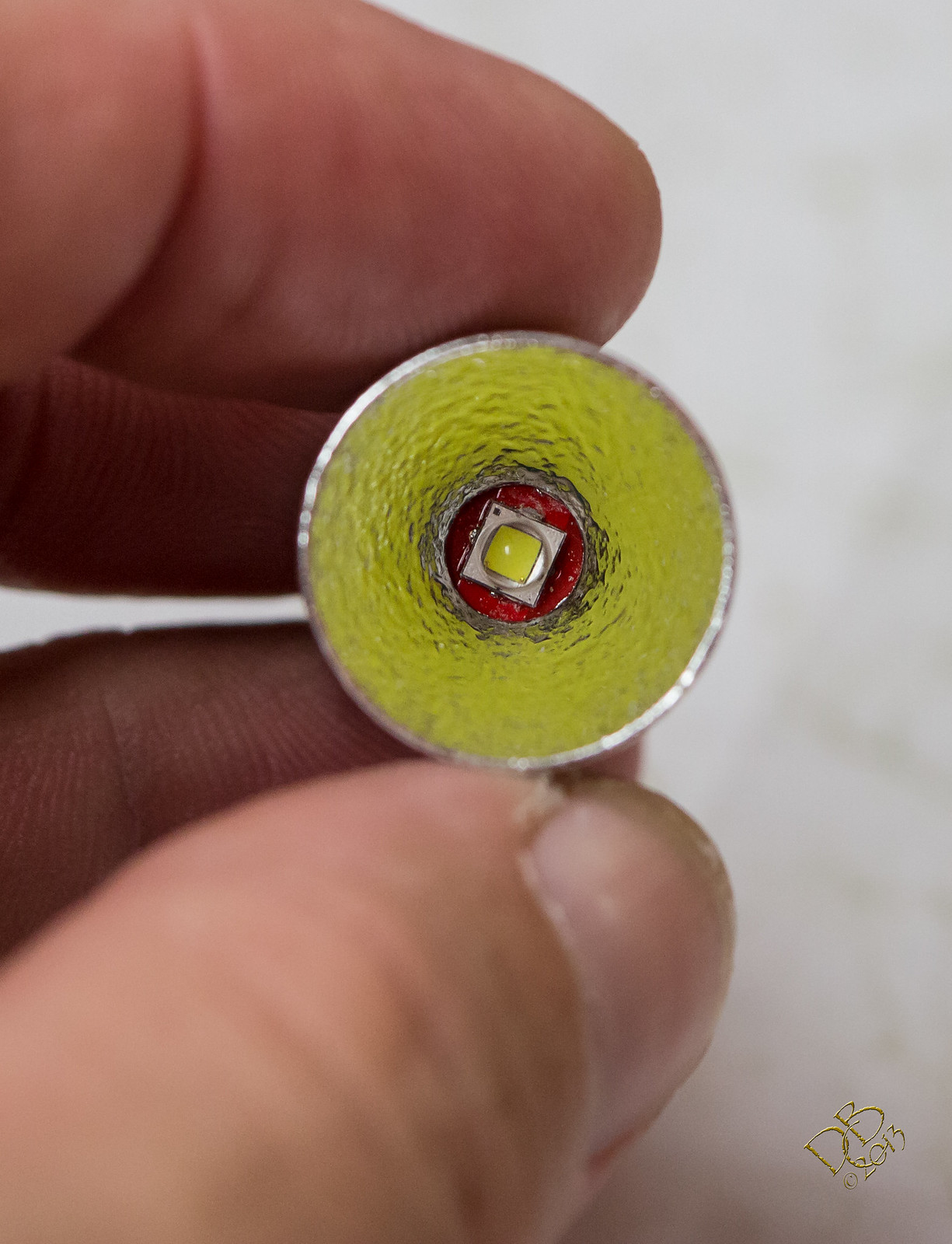

What do you think I should use for focus height? The emitter surface looks to be approx 1mm in height while the top of the dome is 3mm. I was thinking right in the middle. 2mm is 2/25.4 = .079".

I think that I have it now. I'm just trying to figure out where to put the focus point before I spend the next few hours making tiny metal chips.

Buck, I wonder if the previous tools could be reshaped for a slightly smaller reflector? Since the curve is almost perfect, it would’nt take much to make em right. That is, if they’re not already milled and hardened.

Good luck! Hopefully this one is the one you’ve been looking for and the practice is well spent! ![]()

Don’t know what I’m talking about. Disclaimer ![]()

My suggestion would be to try to put the focus right on the die surface, and err on the side of focusing too deep rather than too far inside the reflector.

If you focus on the top of the dome or somewhere inside it and find it’s not right you may not be able to do much to correct it.

It’s much easier to shim the emitter and pull it slightly out of the reflector than push it further in if the focus isn’t right.

Don’t know what I’m talking about. Disclaimer

Linus has a point, albeit it would entail shimming the reflector to pull the emitter back out.

Also, I like de-doming. So the focus would need to be on the actual emitter die surface with no attention paid to a non-existent dome. Does the dome count as a light source? Or is the die face a constant? The dome is clear and refracts the light, but doesn’t count as a new source. Does it? It wouldn’t in photography. Macro focus on the shiny dome surface is possible, but the die face when on or off is still the point of attention when taking pictures of it.

The MT-G2 domed, on high making some 3000 lumens. Taken through a #11 welders plate. Notice the light in the reflector, the entire reflector is filled, no empty ring at the bottom, not missing anything at the top. This is a wide shallow reflector in the Solarforce K3.

Same light, using reflected light to show how the reflector pics up the domed emitter. With a de-domed emitter, the reflection in the reflector isn’t like this. You see the square die in the round reflector.

Notice here the small 18mm McGizmo reflector is showing some of the silver substrate on the XP-G2 emitter. With the reflector sitting right on top of the star, the emitter is too far up into the reflector showing a narrow silver ring where the die surface is not reflected.

And on this light, the centering ring is a problem, showing white in the outer/upper portion of the reflector that is responsible for the hot spot. This light has a large well defined hot spot, but could be tighter obviously if the centering ring were better fitted.

Will have to take a pic of a de-domed emitter showing it’s oddly square reflection in the 3D round reflector.

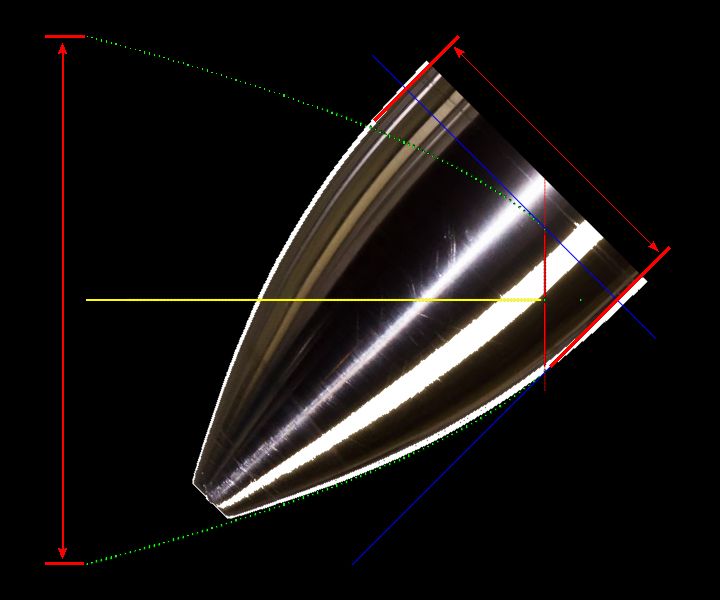

Rescale and shorten or lengthen the parabola to match the diameter of your final dimensions. The focal point of any parabola is set in stone. The desired large end diameter determines the scale. Looks like about 60% smaller than what you’re using but I don’t know what length you’re shooting for.

Sleep? I do but my computer doesn’t. I don’t bother logging off but I’ll start since you mentioned it.

That bottom pic is the Supfire F9 . The one I won from you ( Thanks again! ) had the same problem . I sanded the ring off the centering ring and improved the beam quite a bit . It no longer has a ' three-stage ' beam .

Thanks Jack, I thought about doing that but kinda like the 3 stage beam. Get a good look at the center subject in the hot spot, a nice look at what’s going on around that subject in the corona, and a fair view of everything else in fairly close proximity from the spill. ![]()

Did you sand the ring off the top or take material off the bottom?

Did that tighten up the hot spot any?

That IS the one you won from me! ![]() I thought I’d beveled the centering ring to address some of that issue, but might have taken the above picture before I did that. Might be remembering doing that to a different light too. My memory…

I thought I’d beveled the centering ring to address some of that issue, but might have taken the above picture before I did that. Might be remembering doing that to a different light too. My memory…

Off the top . I still feel that the emitter doesn't fit far enough into the reflector for optimal beam profile ...

I'm taking a break half way through the tedious machining process. Hopefully this is the one. As to the focus height I am going to set up a testing rig. I'll use it to do beam shots in between machining a few thousandths off of the reflector bottom over and over to determine what is optimal.

I should have a pic of the latest bullet soon. Back to the basement for me.

Here it is. The piece on the end is to guide it down the pilot hole.

Are you tired of doing this or feeling quite the expert now? That looks perfect to me. The centering nub on the end should make it track true as well. Man you’re working your butt off on this! Nice work, appreciate you showing us, taking the time to take pics.

Wish I had a lathe. And someone to teach me how to use it. And a shop full of pieces parts to cut on. And a brain. (Hey, while I’m wishin right? ![]() )

)

Fitting lightme’s parabolic graph onto your pic shows the focal point square in the middle of the end of your jig, first visible ring on the taper is about the mouth of the parabola! Success!!!

Truthfully, I am getting tired of it. But once I start something I don't like to fail. I have a picaxe driven stepper motor mod that I've been grinding on for months that is still kicking my ass. But I keep working on it when other projects allow. Someday it will work out.