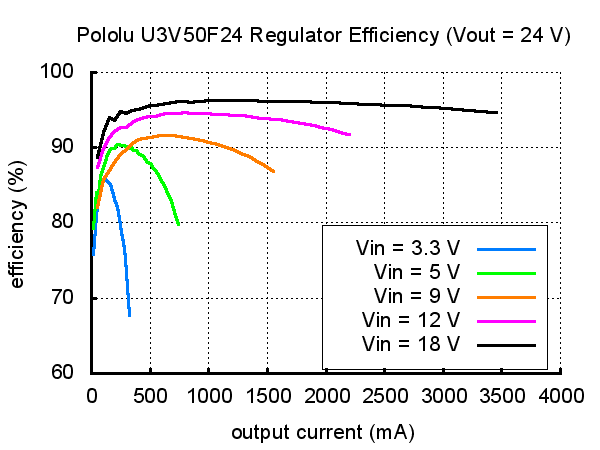

Boost drivers severely drop in efficiency the more you boost the output voltage above input voltage.

Here’s a graph for example:

And now we know why so many XHP35 lights can’t reach their advertised outputs.

I’m a huge efficiency geek. Especially in powerful lights - because then efficiency improves not just runtime but also sustained performance.

I’ve been a big fan of buck, boost, buck-boost drivers.

I’ve been a huge fan of XHP35 HI.

It was hard for me to pick a lower efficiency option….but I believe that for A-lights it just just better.

Why?

- Linear drivers use fewer components…and smaller ones

- Driving even a single XHP35 to the max requires a large inductor, interfering with optics

- the sheer amount of board space required is large…A1S should be possible, A4S - maybe, but the smaller variant surely not

- Cost

- Buck, boost drivers are costly, especially the high powered ones

- XHP35 is costly, especially when you want several

- efficiency difference…it’s not so simple

- high power boost drivers are not very efficient, we’ve seen under 90% when boosting a 6V LED (expect less when boosting to 12V)

- linear can exceed that at high power levels, at the cost of falling out of regulation when battery voltage drops too low

- at moderate power levels boost would win, at super-low there’s there’s nothing like resistor…possible with linear, not with boost

- high power buck drivers should be more efficient than linear, though they would fall out of regulation even quicker

- XHP35 is more efficient than any other LED with comparable throw and this is more important than any difference in drivers

- Q8WP is throwier than XHP35, so it deserves to be used as well. But it needs a buck driver. That would be more efficient

- high power boost drivers are not very efficient, we’ve seen under 90% when boosting a 6V LED (expect less when boosting to 12V)

So it boils down mostly to price and size. But efficiency gains are not superb either.

Quad LED MCPCBs are perfect for compact lights, and running an LED at low currents get extremely high efficiency, so a quad light could get like 200lm/W and still put out hundreds of usable lumens.

I wonder what the most efficient driver for running 3v leds is, either linear or some sort of 1S buck driver that takes 4.2V down to ~3v?

Nichia 219Cs aren’t the most efficient LEDs but you can get over 200lm/W at like 2.8v so that the flashlight could have 500lm regulated output literally until the battery runs out.

Boost drivers are just bad if you care about efficiency, especially if it’s a 12V LED.

For a 6V led it wouldn’t be so bad, as long as you don’t draw much current.

We’re a bit off the topic, but…

I’ve seen one claim of a light making 200 lm/W. This was from Lux-RC.

Say that one wants to repeat this feat with a quad…

What are the losses? With a shallow MgF2 coated aluminum reflector and UCL2 lens you get 95% efficiency. Not including losses on bezel, washer, centring ring. So maybe real 93% is achievable. With cheap reflector that’s more like 88, with a clear TIR (and no protective lens) I would expect up to 90.

What kind of efficiency can you get with a buck driver? Let’s be optimistic and say 99. So to get 200 lm/W OTF you need 220-230 lm/W at the LED. Samsung LH351D can does 150 lm with 220 lm/W and 100 lm with 240 lm/W. So a quad TIR with 99 efficient buck driver could do about 500 lm with 200 lm/W.

If we drop driver efficiency to 95% which I think is realistic, that’s more like 430 lm.

With linear driver, efficiency wouldn’t be good, in the same setup it would be about 78% efficient because at such low currents Vf gets very low.

BTW 12V boost drivers can’t be so bad. It must be possible to make an efficient one. I say so because I observe that nothing gets close to Zebras for sustained output in their size class. Even multi-emitter lights.

And AFAIK Lux-RC does boost too. To 9V.

Running the LEDs at low currents for high lm/W and using high quality optics isn’t a problem, that’s easy to test and sort out.

We just need to figure out which drivers we can use to get high efficiency while the battery voltage is far above the LED voltage, such that it can stay in regulation.

If the battery is fully charged at 4.2, and an LED is running at ~200lm/W at 2.7V, that’s a 1.5v delta.

Maybe we need more people to do driver tests :question:

One interesting kind of driver would be triple channel:

resistor + medium power buck + linear

Resistor for moonlight

buck for low-medium levels

buck + linear for medium-high

linear running out of regulation for turbo

Very efficient moonlight

Very efficient low, medium

When linear engages, efficiency drops initially…but as Vf goes up this combination quickly becomes pretty efficient again, so…

Moderately efficient medium-high

Efficient high

Efficient turbo

In the context of A-lights….

Such construction would significantly increase board diameter. Not feasible for the small ones, but may be technically feasible for A*S.

What effects would it have?

- extra cost

- $3-5 higher driver price

- higher design costs

- less parts sharing

- less deep head fins (or maybe better 2-part head)

- much longer runtime at low, medium levels

- improved sustained performance

Thoughts?