No, it’s not a curious choice for these reasons:

- no benefits of nanoceramic or copper board at Jet-U power level (230-235mA). But decided to go with copper because BLF likes copper and eventually someone will use it in a hot rod lights.

- Faaaaar cheaper than nanoceramic board. $0,6/pc (for 2 LED types at 200pcs per type, 400pcs total all in) vs $2/pc (for 400pcs per LED type). The NC prototyping cost is killing me.

About the maker, I’ll keep it secret to stay alive. But you can find many makers out there using the same base substrate. Bergquist

At 230mA power level, copper doesn’t benefit to almost everything except it can be soldered onto solderable objects. These 10mm Jetusolis/JetuE17A/JetuE21A copper MCPCB already tested against NC board.

Check the my post in your own thread below:

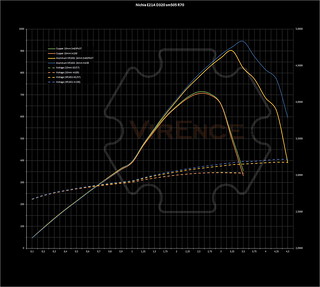

The Indium gain is not as dramatic as in 119D test or perhaps other ceramic based LEDs. Because E17A/E21A has fragile phosphor layer and use polymer base. The phosphor layer burns way faster than ceramic base LEDs before the actual die cooked. I only did controlled test on 4pcs E21A to save time. The rest of the R70 tested at 2A starting point (60 seconds stops for current ramping) just to cross check/validate my finding. The controlled test done with 3 minutes for each steps. This what makes the burnt patterns looks different. Beyond peak current, E21A phosphor layer slowly degrade and burns at several hottest points.

- Clemence