I know that, with the exception of LiFePO4, Li-Ion batteries don’t maintain a (more or less) constant voltage as they are discharged the way NiCads do. Would using IMR batteries NOT result in a drill that loses power as the batteries are drawn down, especially since a NiCad drill probably has no voltage regulation?

I can’t say ill object to any mod whatsoever.

Nice work!

soldering to terminals - scuff them up with a file or carefully with a dremel grinding wheel. Then tin terminals and wires separately.

power over discharge curve - although the packs I’ve built (5S, 18.5V nominal) discharge down to 15V I haven’t noticed any difference in power of the tools I’ve used them on over the discharge curve. Some of them (strimmer, hand vac) are pretty brutal on batteries, but they’ve all been fine. I had to use one of the old NiCd batteries a while back after a polyfuse tripped in one of my DIY li-ion packs and that was completely miserable - power was down and only got worse. At the end the strimmer was just gently brushing the grass ![]()

If you’re going to use serial batteries and charge them as such, either get a hobby charger and balance charge them or a PCB with built in balance charger - imbalanced batteries will go boom eventually. If you’re skipping a PCB, then get a voltage monitor or alarm as you can very easily destroy li-ion batteries by overdischarge and depending on power draw/ battery configuration you can do that without even realising it.

+1 I tend to lightly sand the terminals with a dremel before soldering. I also use extra flux and a 180 watt soldering gun. I haven’t tried it with anything less powerful although I’m sure it can be done… I like to be in and out of there in about two seconds.

That’s right, you want to use a lot of heat for a very short time. Nothing wrong with that, contrary to what many will tell you. After all, when packs are made, during manufacturing they heat the terminals up so hot as to weld them to the cell. It’s called a spot weld. Extreme heat for an extremely short time. A big iron can do that, a small one can not. Using the small iron is what will get one in trouble.

If one does not know what they’re doing, they better not try.

Nice thanks, I will try it. I have a hobby charger I can wire in.

Just curious. Anyone try IFR rather than IMR? It seems like it would be a better choice for packs with multiples of three volts (ie 6V, 12V, 15V, 24V, etc). And they are very rugged, produce LOTS of amps, and have a nice, flat discharge curve.

you’re welcome ![]() I have a voltage monitor backed with velcro that I swap between whatever battery is being used. It flashes a warning when that cell drops below 3.4V, so it’s easy to keep an eye on discharge state.

I have a voltage monitor backed with velcro that I swap between whatever battery is being used. It flashes a warning when that cell drops below 3.4V, so it’s easy to keep an eye on discharge state.

haven’t heard of it, simply because those cells are relatively hard to get hold of. The high discharge cells (IMR?) are sometimes used, but most of the time it’s whatever’s been salvaged ![]() I’d love to get hold of some high drain cells for packs that I can’t fit a 2P set up in, but I’ve never found an old pack to salvage and I’m not going to pay money for cells when I have a salad draw full of 18650s and lipos!

I’d love to get hold of some high drain cells for packs that I can’t fit a 2P set up in, but I’ve never found an old pack to salvage and I’m not going to pay money for cells when I have a salad draw full of 18650s and lipos!

Ok Ive had time on my hands since the last post, i followed the link and purchased the hp 12 cell pack for 15 bucks. Carefully i burned away at the plastic joint with a pencil torch andgotto the batteries. They are blue panasonics 2200mah. Wired 6 of them up with the balanced hobby charger setup which i borrowed from some old lipo batteries my brother had laying around. They were actually fullly charged. 22.8v for all 6 cells.

When i put it in drill 18v pack and hooked it up to the drill it runs several times within 30 secs but really weak and it dies out. I measure the voltage and its still high and after waiting like 30 secs the drill will run again but die out. I leaning towards giving up on these li ion and getting the original NiCd thoughts??

These drills pull lots of power with the factory 1.8 amp nicd now this 2.2 amp li ion is way weaker basically unusable.

Sounds like you’re trying to run a drill on LiCo laptop cells. LiCo just can’t supply the amps a power tool needs. That’s why power tools run LiFePO4 or LiMn rather than LiCo. Also, remember that trying to draw this kind of current from LiCo is downright DANGEROUS!

I love the people on this forum. Ohh well i built the pack and im running it on a dewalt snake light that I rigged up with a 6w mr16.

Will start looking into this new Lifep04. Thanks

Hmm. . . Mod these junky incandescent power tool "flashlights" with LED MR16 bulbs. Great Idea!

-Thanks.

Works like a charm too because the built in driver on the mr16 steps the voltage and the current down so it works on any crappy incandescent 12v and up. These MR16s are down to 3 bucks or so for 6w which is decent power.

12v and up? How far "up"? I've got a "19.2v NiCd" one.

-Garry

Good question, Makita 18v Lithium packs are 21v when fully charged

I never thought of putting an MR16 in any of my cordless drill flashlights! Nice!, now I can have more projects to do ![]()

GottaZoom is right, 18V cordless drill batteries charge up to over 20V. I seem to remember that the MR16’s that I first bought could run on 12-24V. I looked at a couple on the internet, but I could not determine that.

So, I took an extra that I had, standard 3W warm white MR16, and hooked it up to my power supply. Here are the readings.

10V - .06A

12V - .21

13V - .29

14V - .29

15V - .27

16V - .23

18V - .18

20V - .15

22V - .12

24V - .10

and for good measure, I ran it up to 26V and got .09A

This is voltage to the external pins of the lamp and current through the external pins, not the current to the LED’s

The perceived brightness was at a maximum at 14V and decreased slightly from 16V on upwards to 26V. It wasn’t much, but it was noticeable. I will measure the current to the LED’s and post that also. It could be that these lamps are regulated and maybe 18-20V input is no problem. If that is true, then these lamps in cordless drill flashlights would be a sweet setup with no modifications to the lamp at all.

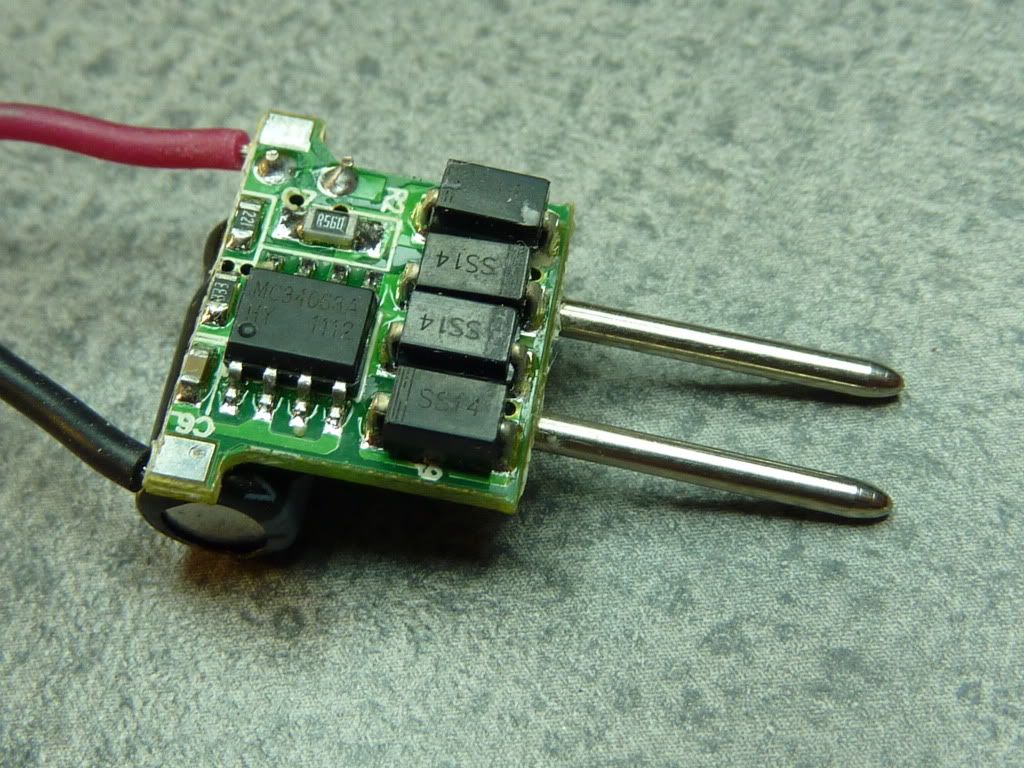

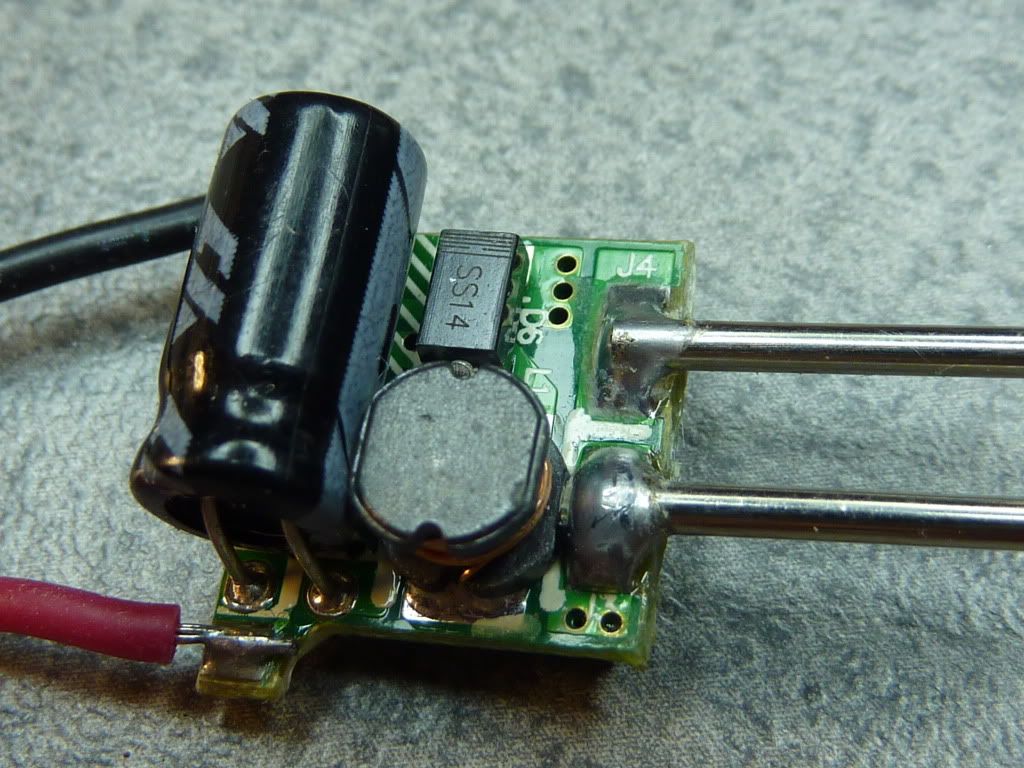

I took the lamp apart to measure the current to the emitters at the various input voltages. I wanted to separate the driver from the lamp for the bench test and this is what i found.

Even though I didn’t run the lamp very long in the previous testing, the driver got hot enough to melt the plastic housing. It still works OK, but I don’t think we could count to last too long at higher input voltages. I have some more of these lamps, I will disassemble another and do the measurements including the temperature of the driver while it is running at 21V input.

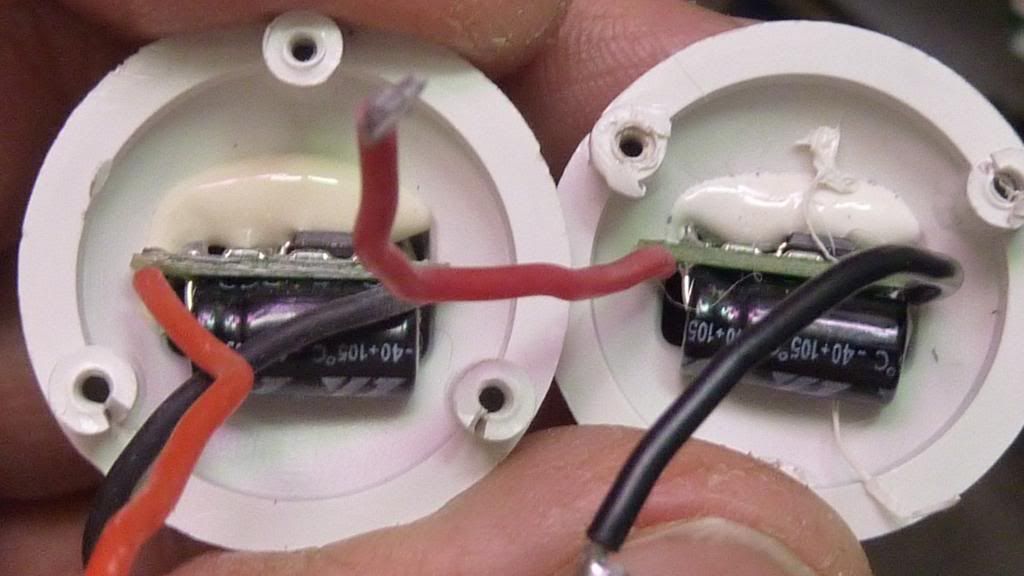

Here are pics of that same driver from another post of mine, My $3.96 florescent worklight Mod

Thanks Dave for testing! Would make a really sweet setup to use these!

- Garry

off topic maybe,

Put one of these in a Makita drill for 7.2 volts?;

http://www.fasttech.com/products/0/10002233/1292001-218650-battery-case-with-lead-wires

Or are there better quality ones that stands more amps?

I retested running the driver in the stock MR16 on voltages up to 24V and it is fine. It doesn’t even get hot. It will be fine, as is, in a cordless drill flashlight up to 18V. What I saw and thought was melted plastic turns out to be glue to hold the driver in the base of the light.

Oops. ![]()