Efficiency. The only way for a high CRI LED to achieve high efficiency is with low light intensity. Therefore, they chose not to use a thermal pad, as it would not bring benefits for the intended purpose. Edit.: I think it is aimed at markets where efficiency and light quality is a priority over the initial cost of installation.

The only catch to this theory is that this LED is also available in 70 CRI, and also in a version “optimized” for flashlights (whatever that means).

The B35AM is an LED in the full range of CCT and CRI. Assuming this strange design because it is also available in high CRI makes just as little sense to me as the missing thermal pad ![]()

I think the only real reason why they do this is to save some cents of money per LED. Nichias LEDs are sometimes strange anyway, the same weird design choices are also done to other LEDs with 70 CRI option available (NV4W144AM for example). It’s kinda funny that Nichia advertises these LEDs as “Super High Power” - compared to the competition it’s more like “Mid Power Range” ![]()

You have a good point. But price and efficiency are related. Let’s say that the relation LES/price is improved, resulting in a lower cost for high-efficiency applications. For example, if you compare with XHP50.3 hi the efficiency is about the same at lower currents, where the emitter is probably going to operate on most applications.

Nichia has been doing the two-pad thing for a while, which is probably why there are only about three flashlights on the market using the 144A.

At the moderate power levels Nichia intends, it isn’t as big a deal as it is for the things we flashlight nerds tend to do to LEDs. For most mains-powered lighting fixtures, adding more emitters when you need more power is an easier option than it is in portable lighting.

IMO moderate power levels are right for high CRI emitters, as at higher drive levels the CRI degrades noticeably (due to the blue spike) and the increase in heat just isn’t worth it. What really annoys me with these Nichia emitters is the proprietary footprint, which introduces a lot of work finding the right boards and optics and whatnot. But again, I don’t suppose they care at all about our tiny corner of the LED market…

I’m a certified CRI baby so I’m content accepting some heat and a bit less output, even in fairly powerful lights.

I’ve seen a few high-CRI lights with a lot of CCT shift on their highest modes that still make good CRI numbers on my spectrophotometer. When there’s a loss, it’s usually only a couple points, and the color rendering looks much better than low-CRI emitters to my eyes as well.

They do advertise it for flashlights, and even at only the continuous rated power of 10.5W it likely has non optimal performance on a standard 1-2W/m.K dielectric MCPCB, Nichia decisions just make it more complicated/costly for integrators for no good reason.

As I found out from the TLF now d1 with B35AM consumes only 3.7A on the tail from the fresh battery so this is just about 2A on the led. Of cause this is safety. Safety low.

As Nichia claims - absolute maximum rating only 1800mA

This.

And to be honest, I don’t think Nichia’s marketing is good on this. “Super High Power” (as Nichia advertises the B35AM) is nothing here, at least when the competition is used as a comparison.

That’s my biggest problem with it - the lack of a thermal pad is simply an absolute dealbreaker as soon as it comes to good performance, the only thing that remains is the perfect light quality and very good light image in conjunction with optics (reflectors etc.).

There is a reason why Cree, Luminus, Osram, Lumileds and many others include a dedicated thermal pad in their high-performance LEDs. Certainly not only to enable massive overcurrent.

Well, Cree does that too, the XHP35.2 Pro9 “Extreme High Power

LED” is rated for 700mA/12V maximum ![]()

Yes, but they still have a dedicated thermal pad, which allows for better cooling and much higher drive current (if cooled as good as possible). With this extremely low thermal resistance of only 0.7 °C/W (compared to 1.8 °C/W for old XHP35) I think 4-5 Amp could be easily possible - with 12 V instead of 6 V. Maybe the footprint itself (along with the smaller thermal pad) limits the maximum possible drive current.

With the B35AM, this LED limits it’s maximum performance by (questionable) design, not by the LED chip itself…

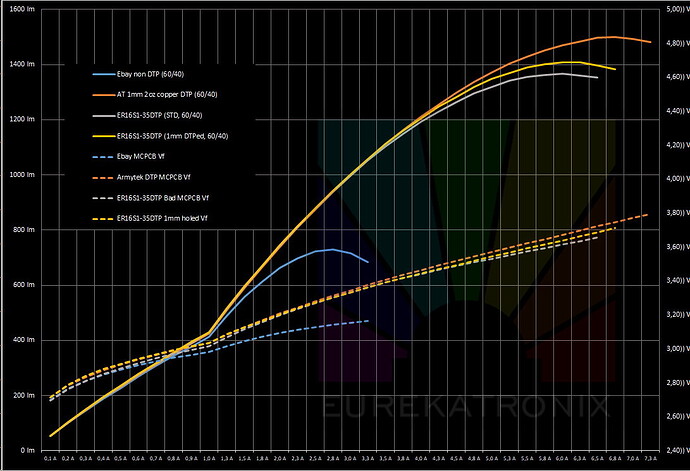

BTW here’s Eurekatronix’s non DTP MCPCB (grey, don’t pay attention to the name saying DTP) performance with a 319A (3535 LED with neutral thermal pad) vs a DTP MCPCB (orange) and a random non DTP MCPCB (blue)

Up to 3.5A (12W), there is virtually no difference with DTP, at 5A (18W), it’s about 4-5% lower than DTP

The random MCPCB is of course pathetic, even providing subpar performance at the 2A continuous rated current.

Another thing to consider is that the pads area of the B35A which is larger than the central pad area of an hypothetical B35A with neutral pad. Thus it’s possible that it would cancel out the slight performance disadvantage of the high perf non DTP MCPCB.

So in conclusion I don’t think that an hypothetical DTP B35A would offer substantially better performances than what your B35A on Eurekatronix MCPCB test shows, but it would allow easier and cheaper integration.

I think it simply depends on the design of the LED package itself, and in particular on the thermal resistance from the LED chip (or the four individual LED chips) to the thermal pad/contact pads.

If I look at the specification of the B35AM in the data sheet (1.5 °C/W), there is definitely still room for improvement compared to other LEDs such as XHP35.2 HI with 0.7 °C/W. I can imagine that a dedicated thermal pad is essential in order to achieve such low thermal resistances.

The point of simpler integration remains, of course. However, another thought occurs to me in this regard: what if Nichia is deliberately using these footprints to operate a kind of “vendor lock-in”? After all, it is not easy to change the design of the LED board or carrier board for every application outside of flashlights. This may still be possible in flashlights thanks to the separable boards and the most commonly used standard dimensions (16/20 mm), but what about lighting or downlights? It might not work so easily, especially if a large LED board is used for tens of LEDs or if it is embedded in a specific design of the end product…

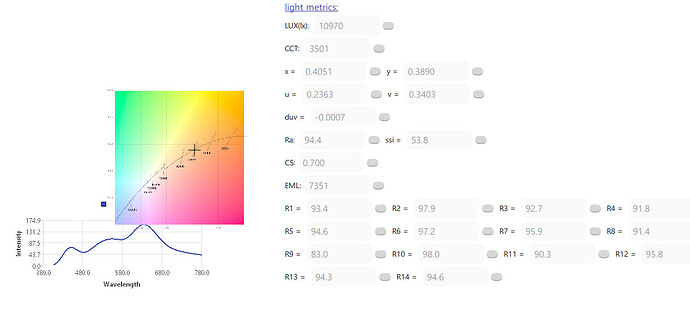

Does anyone know how the tint is on the 3000K or 3500K B35AM from Simon?

I’ve been considering it for my next flashlight since I don’t have one yet, but I don’t want a non-rosy LED. And as an alternative, I could just slice a 519A.

Not as accurate as a proper measurement, but that’s what my Opple LM4 with steves new Windows app says. B35AM 3500K, bought from Simon, in a S2+ host with pebbled TIR. Last time I measured it I got a DUV of 0.0003, so the results seem to fluctuate quite a bit… That was at a different power level too, though. Seems mostly neutral, not particularly rosy, to me. Maybe add a AR coated lens that lowers DUV?

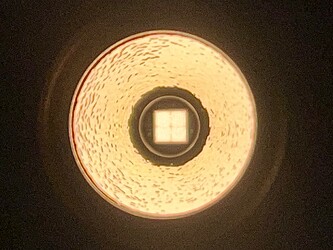

some convoy b35am pics here

it looks like the b35am tint is not rosy, it seems similar to domed 519a, which is not rosy either. I like to dedome my 4500K 519a…

It would come in an S2+ so the green AR lens would help. I’ve seen slight, but noticeable improvements in my flashlights when I swapped out the old AR lenses.

I did a lot of searching for info and read many posts, but that was a new one - thanks. The 3000K 519A in my copper T3 is actually rosy. I was planning on dedoming it when I bought it, but it’s so nice that I kept it intact. Others have been pretty neutral, which is still a lot nicer than the previous LEDs that some of them replaced.

Despite its non-rosy tint, I may give the B35AM a shot. Hard to resist with an efficient boost driver which is now at the proper current to prevent the smoke monster from appearing. And I already have so many 519As.

I anticipate I won’t like it as much as my quad E17As, but at least I’ll be able to see the 4 LEDs thru the lens. ![]()

me too… I have some FFL350RD 3500K coming to try next

I hope you enjoy the B35AM… I look forward to your impressions

Well 6 months later, I finally got a “3500K” B35AM installed in a brass S2+ with a green AR lens. I ordered the LED and driver before Simon made the B35AM as an option with the S2+, which is fine by me since I prefer to assemble it myself.

I am pleased with the tint since it’s slightly rosy. BUT, the CCT is more closer to 2700K than 3500K. Maybe Simon sent me the wrong LED? I’ve read that others have experienced the same recently though. Regardless, I like it.