The lens link goes to the original post that has the link in it. It doesn’t matter though; they are all gone and the seller cannot get any more.

I strongly recommend you braid the springs; you will fall out of regulation quicker without that mod.

Thanks O-L, it has been a fun mod. I have some more to do, the most difficult for me; machining. Wires and tiny components; no problem.

After read relic38 mod on this YinHex YH-X9 & Old-Lumens on the FandyFire / SRK King king mod, that inspired me to follow the steps to mod my Apex 5T6.

Mainly because the original driver has annoying low PWM that I sensitive to.

Here goes :-

Out the driver

Before . . .

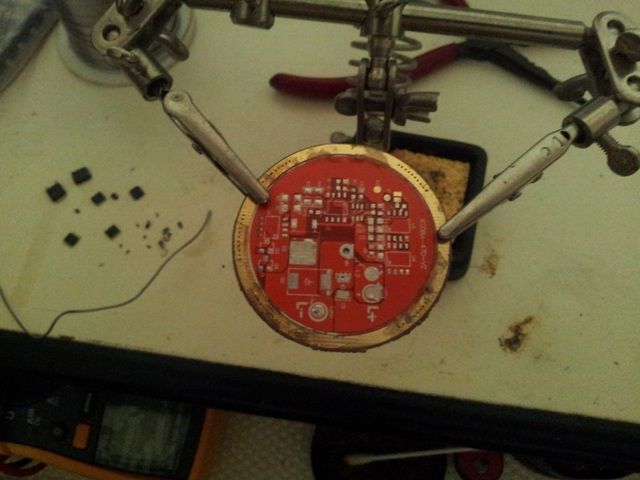

After. . . clear off the original components, wicked & clean with denatured alcohol.

The Master & Slave

Set to three modes, typical Low, Mid & High, not really going high current drive, just a shy of twenty 7135 chips. (350mA x 20 = 7000mA, 5 LEDs in Parallel, so each get 1,400mA in theory, also my first time stacked it & worked! ![]() ) due to the limited thermal transfer path from the mcpcb to the head. I also did the added braid or wick wire to the springs.

) due to the limited thermal transfer path from the mcpcb to the head. I also did the added braid or wick wire to the springs.

Well that just about for it, retrace the positive and negative path on the original plate, connect with big wire for current. clean off the adhesive residue on the rim where the driver sit & the driver plate, dab some Dunlop glue & put it back all together with batteries in it to add some push for the glue, test three modes runs perfectly ! Let it sit overnight babe ~ :bigsmile:

Thanks to relic38, Old-Lumens as well as other modders ! Hurray BLF ~

iron potato. Do you know how many people on this forum, if they attempted this mod would have success? Not many. Job well done.

Thank you MRsDNF ![]()

I bend those 7135 chip tiny pins, thin angled soldering iron tip, wick wire, tweezer, soldering 3rd hand & flux helps ~ oh ya, afterward remember to clean it with denatured alcohol ![]()

looks like you have a stack of space inside the head for improving the pill. Can you find any places that sell alu rod in a matching diameter? You could then ask them to cut you some slices off (I think Old Lumens did this for his Mag heatsinks - ask him :laughing:, then drill 3-4 holes through the PCB where there aren’t any traces and tap the piece of alu rod so you can screw it all together with some thermal paste in between. Hopefully you’ll be able to get the right sized piece of rod, if not you can go a little undersize and wrap it with copper. Should make quite a difference in heat sag and thermal transfer.

Thanks for the heads up mattthemuppet, I might try my luck at machinery shop to ask them turn a piece for me ![]() lovin it without the annoying low PWM now :heart_eyes:

lovin it without the annoying low PWM now :heart_eyes:

My light, cheap XM-L2 version had different driver. Easy to resistor mod to 10-12A. Stock was 3,9A.

Same hollow body. :Sp And super crappy screws, some even missing. Well secured tailcap, probably glued. Here is how I easily got mine off:

Unscrewed all four screws at the back. Put in two long screws (about 3 cm). Put the two screws in the vise. Two strap wrenches.. Not a scratch and great leverage.