fiddlesticks - ~4mm too small

thanks

fiddlesticks - ~4mm too small

thanks

No problem, glad to help.

I planned on putting up pics of the battery holder tonight, but there was a short and some springs melted.

Seriously. I probably should use protected cells instead of IMRs next time for testing.....

I'll try again tomorrow with some Old-Lumens styled homemade copper springs.

Here are the details of the battery holder mods.

Overview: Converting a 3x18650 battery holder from parallel to series operation.

Here are a few pics of the stock battery holder:

As you can see, the holder needs to bring both + and - to the top end, as the body does not have a ground path...it's entirely anodized.

The first modification was to cut the trace on the PCB, linking two spots on each one. I failed to notice these initially, and this led to a short (and melted springs.)

Working from the switch to the top spring, linking + and -, requires a bit of wire:

The extra wires are used to make for a better negative pathway:

Here you can see the addition of 2 contact points to the negative (ground) ends:

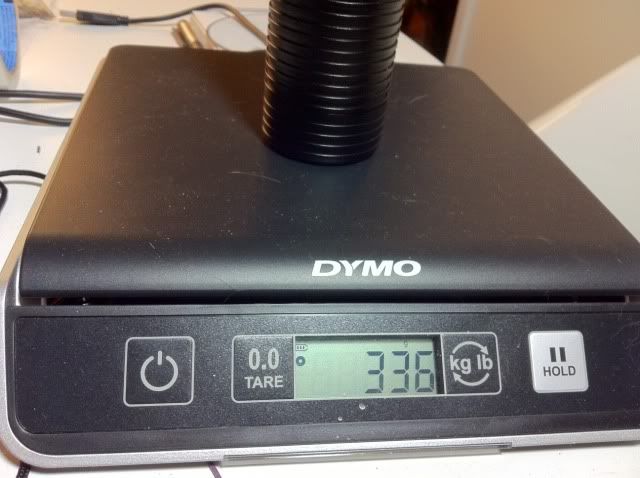

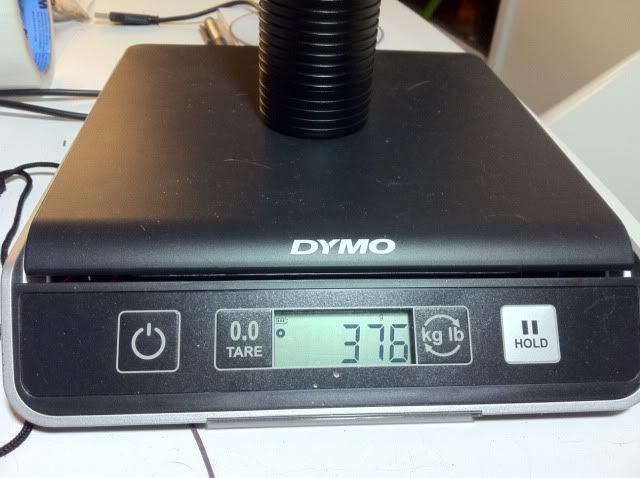

Here's a look at the modded holder, reading 12.61 volts:

Next round will be the assembly/wiring of the Light Engine.

I mean, since the plastic legs are stuck right on the heatsink, that they could get warped from the heatsink temps. Obviously they don’t since so many use them. I was just asking, since the stock puropse is for indoor/outdoor lighting where the heatsinks are usually finned for cooling.

That stock battery holder sure is a lot better looking than the plastic junk ones I'm used to. Looks like it's going to be a great light when you're done!

WTG - Chicago

Chicago-X,

Excellent work so far sir! I like the work you've done on the battery holder.

If you'd like to see a spoiler of the beamshots, take a look at this build I did back in April using the same emitters/optic combo comparing it to a zebra SC60 and everyone's favorite MF 3 mode XM-L drop-in :)

Despite the narrow specs on the optics, prepare for a huge wall of light!

p.s. - yup, machining copper can be a pita... :)

Thanks Old-Lumens and Match for the kind words.

Nice beamshots, Match. It looks like the 'wall of light' of legends yore.

There is also an individually-addressable 3-up board available for those not wanting to mod the battery holder.

It would, however, require a different driver (or sandwich)

Update:

I broke my lathe machining the stubbornness out of some heatsinks for Old-Lumens. The repair parts just landed, and I should be up and running tomorrow if all goes well.

The driver pictured above is now listed on the cnqualitygoods.com website.

Please stay tuned for more updates and pics to follow.

The 3-up board has been soldered to the driver:

A thin film of Arctic Silver adhesive was placed under the board, then the optic placed on the board, then the whole assembly put under light pressure. The AS should hold the optic in place, obviating the need for CA glue.

Next will be affixing the driver to the light engine.

Since this thing is going to pull 4-5 amps at 12.6v, I wanted to upgrade the wiring I had on-hand. I used some silver plated copper Teflon-coated wire:

Here's the upgrade:

Some heatsink stuff from another light was placed in the driver pocket:

The modified wiring was then soldered:

Since the original pill screwed into the head, I needed a way to provide positive pressure to the bottom of the new light engine. The original pill was used:

I cut a ring from the heatsink, then notched it for wire clearance. I may want to upgrade some day. :)

Here's the battery plate soldered on:

Buttoned up, stock and modded:

Before, without cells:

After, no cells:

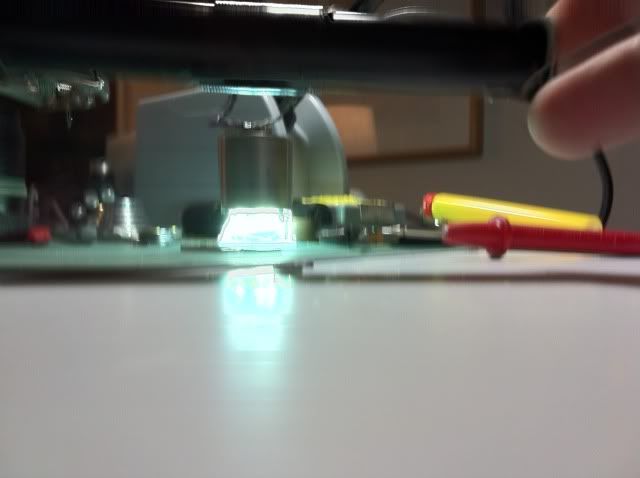

Testing.......IT'S ALIVE !!!!!

Next come the night-ending beamshots.

When turning copper alloys try increasing the back rake angle of the tool and if turning slow, speed up. Most copper alloys work harden when turned slow. Sharp HSS tool with a 20 degrees of back and side rake with fast light cuts work well for me. I grind my own bits for copper and aluminum. Most of the carbide ones have angles for steel.

$00.02

Larry

I didn't like this light, solely because there's no change in diameter at the head (iow, looks).

Now you have gone and changed my mind.

I have actually started keeping a prioritized list. Time to figure out where this fits :)

Thanks for the tip. As a novice machinist, I appreciate all info.

Here's a quick iPhone pic. On the right is the stock 700 lumen single XM-L CQG light at 2.8A, on the left the modded 3 x U2 XM-L at ~4A (turbo) estimated at ~3000 OTF.

Even my wife said "wow" at the new torch.

If you want to go with "old school" info check this out.

http://dale.chatham.org/Interests/MetalWorking/HowToGrindLatheTools.pdf

wow is right. that's my kind of beam right there. or even more flood.

Nice work sir! Let me know if you ever start selling these... :) The aesthetics of your light are, well lightyears ahead of the DRY. :bigsmile: To say nothing of the build quality.

Frontpage and Sticky for you.

Wow, my first FP/S !!! Thanks !

I may sell this one, as I ordered 2 more hosts. :) I wish they were a bit more budget...the host is $45 (edit:host only is now available for $35+s/h), the board and optic right at $40, driver $5 (all plus shipping), etc....I would need to get close to twice what the DRY is selling for in the GB just to break even, then pay myself $0.50/hr.

Thanks again, LarryB. As I said, I appreciate all info. I'm currently poring over "How To Run A Lathe" 1949 edition. It's an awesome resource that hearkens back to a simpler, more honest time.

Well definitely congrats on a job well done.

By the way, you are on the frontpage, just a little ways down because this post was started a while back, and it sorts by creation date.