That gap looks severe. Checking my XM and MT-G ones now… Yeah, there is a small gap there. Seems about 0.1mm or so.

SinkPADs appear in the picture to have a gap too, but I checked a bunch of mine and there is no gap, it is flush with the dielectric layer.

Think the gap on all three Noctigons is about the same depth, but because the XP is such a small pad, it shows up easier.

I took a closer look at the rest of my noctigon mcpcb’s and some are better than others. Of the 6 XP boards I have one is what I would rate as acceptable, four as marginal, and one as poor. My XM boards are perfect though as far as the center pad height is concerned.

Perfect, Acceptable

Marginal, Poor

For the price point these mcpcb boards cost I don’t expect perfection, just a little bit more consistency in QC.

For SinkPADS, I'd sand them heavy, 320 all the way to 2500 in 8 steps or so. For the Noctigons, I don't believe it's necessary - I lightly hit them with just the 2500 grit just to be sure the surface is smooth, no rough edges, etc. Still with only 2500 grit for a short time, the gold plating comes off a little bit.

The noctigons are a big advantage for me in this alone.

Why don’t you use a polishing wheel on a dremel?

Solder them suckers to the pill, surface finish doesn't matter if you do that. :p

slightly off topic here but does anyone know a source for copper mcpcb boards for sst90??

or anyone on blf who makes them?

Not sure how that would work to get the surface flat and get rid of the micro ridge lines, etc. Maybe for an end step but will it really polish as well as 2500 grit paper?

bowhunter, I recall people build custom pillar-type copper stars (often it’s the whole pill) and solder wires directly to the emitter pads. Other than the custom route, or buying an actual CBT-90 ($$$:money_mouth_face:, there are not many options.

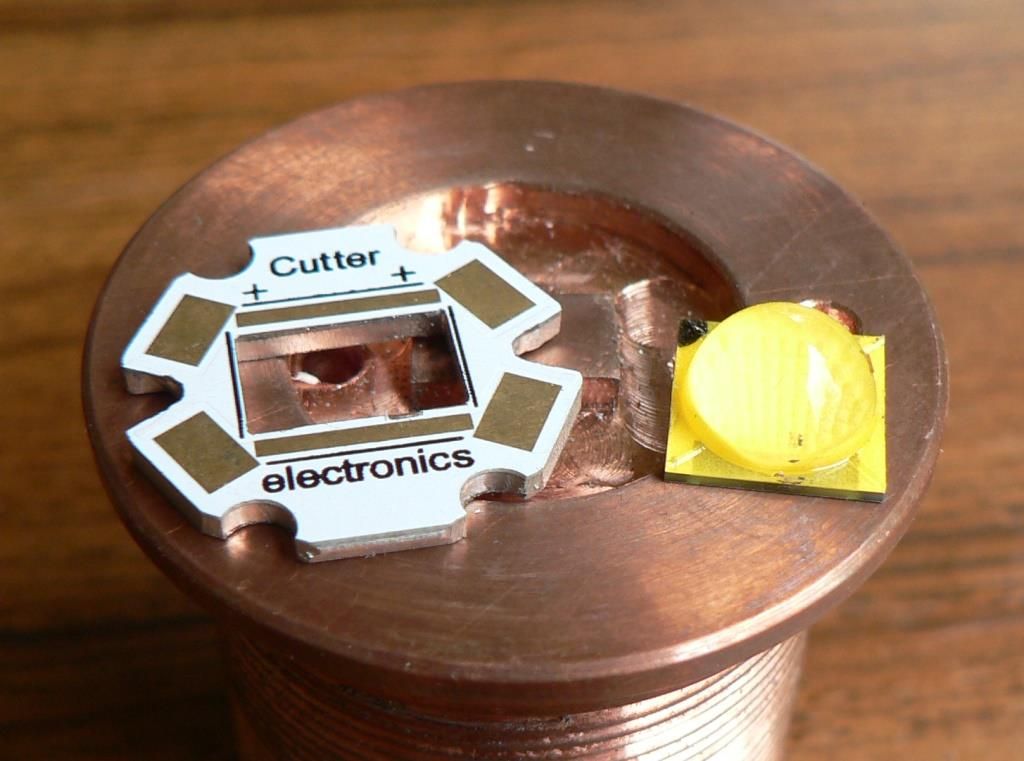

Like this.

Bingo, wow that looks cool. Direct bonded to the pill! :heart_eyes:

Is that something you built yourself? I don’t know about others, but there’s something visually about builds with copper that I really enjoy just seeing… like artwork :)!

Yep, its one l’ve made but as yet not finished. Long story. One day when thing settle down I will finish the light.

Sorry for resurrecting this topic.

This weekend I played with some parts, wanted to polish them for better looks and decided to to shineup one noctigon star:

copper

aluminum

brass

and noctigon star which, for some reason, does not look like copper!!!

Maybe they have some plating on them? like nickel or something similar?

Looks like nickel to me. And looks somewhat thick (in plating term), since polishing didn’t reveal any inner layer at all.

Keep polishing & you’ll get to copper. What your seeing there is the nickel layer. ENIG plating

They do a layer of nickel before the gold because copper atoms will diffuse into the gold layer with direct gold-on-copper.

Been discussed before... there has to be a barrier layer between the gold and copper. Hit it with a file and you can definitely feel the difference when it cuts through the plating layers and hits the copper underneath.

Very disturbing picture… ![]()

Did they improve this on the later batches?

If intl-outdoor just provided a link that describes the gold / ENIG plating it would prevent many from being concerned about it.

Even on that noctigon at least its better then sinkpad-II.

They have stopped trying at all. No copper pillar raised up to meet the led’s thermal pad. Instead its a hole.

ENIG is the process and there's is a nickel layer before the gold, nickel is tougher than gold, gold is a very soft material will go off not only because it is thin, but because it is soft. That is standard in printed circuit boards.

Also that myth that ENIG is going to affect the thermal transfer is busted here. ENIG board vs bare copper.

Very exaggerated issue, check this post. https://budgetlightforum.com/t/-/22412#comment-552618