Aight, so being my pics in my “introduce yourself” thread got so much attention figured Id go through whole thing with my light.

Understand though I’m no expert, no fancy equipment just a good solid basic knowledge of things and love to tinker and fabricate things. But years in custom building rcs, being a ase tech, so on learned alot over the years.

First off Securitying and Mudder are the “brands” for this light on Amazon Prime. Being such, they get attention and alot of ppl buying them over Yinding. Though Yinding does 2 things better out of the box. I am ordering a yinding in a couple weeks with some other stuff, so Ill be applying my new “skills to it lol. And SS X3 (real not clone) be here hopefully tomorrow.

Version I have because I needed a light QUICKLY (commuter light broke)

Securitying Clone

Amazon clones are V1 of the KD 2. XM-L emitters not XM-L2 U2. Driver is the EXACT SAME (AWESOME!)

low/med/high all 3 can be programmed from 10-100% light output. Strobe is function of first turn light off the push and hold.

Problems out of box: well only 1, HEAT MANAGEMENT. The emitters are attached to a single oval shaped aluminum plate that is attached by screw from back side (remove rear cover/driver). This plate is 1mm+ from outer casing so only screw holes touch casing itself. Plus casing is very thin and light weight except back cover, it has meat to it,lol.

Output aint bad for something so small but thermal step down (yeap has that safety too) kicks in QUICKLY when light is on high. Driver (before losses) puts out 2270mA in series for emitters. Not bad.

Stock battery, seemed ok but I had SS 4x protected battery cases arrive day before I got this, so just yanked cells after initial test run, and used balance charger. Everything in box works, just cant say how well.

Onto the fun stuff, MODS:

Upon opening light I found the heat issue instantly, the aluminum plate for the emitters. How to fix….

Version 1.0 Aluminum plate 0.6mm thick (what I had on hand)

Simply cur plate, bent a long “tab” to extend internal length of top of case, drilled holes for mounting screws (had to elongate lower hole in emitter plate so could put a lower screw in) some thermal pastebetween plates, tab and case, plus front side of plate at screw holes, and away we go. Big help with heat but far from enough

V1.2 0.4mm COPPER plate.

Same thing but expanded to cover entire emitter plate and longer tabs to wrap around inside of case, more contact area since copper conducts heat twice as fast as aluminum. Thermal paste again of course. NOW WE’RE TALKING.

Can stop at v. 1.2 if keeping stock set up, thermal testing (get to that in a bit but figure 7mph wind speed) had it staying away from thermal shutdown down in safe range (high side but safe). Upgrading to XM-L2 U2 emitters, which I did on the STOCK PLATE using a soldering iron (mistake turned into way to reflow) helped temps a bit too because I could run “high” at lower level for same “visual” light output.

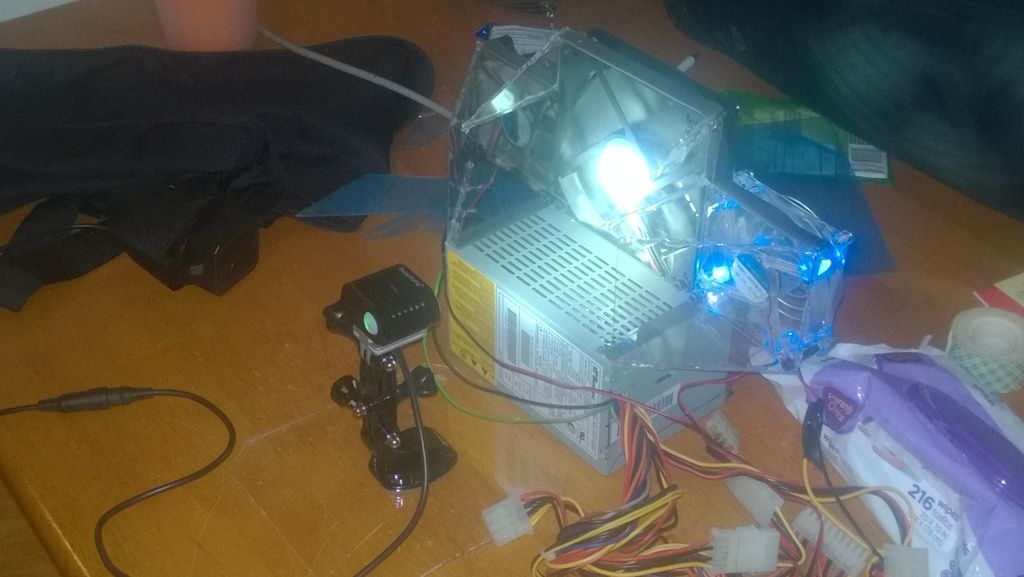

The “thermal management” testing equipment. All temp readings are in degrees F and taken internally at emitter backing plate:

V 1.2 Thermal transfer plate and XM-L2 U2 at 100% test

“Air Flow Generator” is pretty obvious, things I had in a “junk” box in the basement. CPU PSU converted, 3 CPU fans then some lexan sheet I made into ducting.

All “cleaned up” and 12V DC power functional instead of fans just plugged into the wiring mess.

Light is mostly complete now, next post here will contain next “chapter” (wife and baby dragging me away from comp,lol)