Anyone have any before-shave/after-shave beamshots for the XHP50.2?

thank you.

Anyone have any before-shave/after-shave beamshots for the XHP50.2?

thank you.

Dedoming these most definitely does not reduce surface intensity. It increases it. Sorry if my notes misled. They were my lab notes without the context I had when doing the work. I was only concerned with how well the XPG3 performed vs the top dog XPG2. Each of the sections in the data are relative. The first numbers were dome on surface brightness through a lens. The third section shows how well the XPG3 performs dedomed vs the dedomed XPG2.

I would think that regardless of whether there is a lens (dome-on) or not (flat dome or flat lens), the total light output (lumens) should be the same since the light-emitting substrate has not been disturbed and the clarity of the covering has not been disturbed. If the total light output increases with a dome-on, this is like a “free lumens” or “free light energy” situation which, IMHO, is a violation of basic physics.

However, dedoming (mechanically removing the dome completely) does disturb the substrate and may cause microscopic damage so I can see the light output decreasing due to this.

When I read lumen ratings which are higher with dome-on (usually about 15% to 20% more than flat dome config.), I tend to assume the measuring instrument is not measuring properly (a shortcoming in our light measuring technology at the moment) - that is, when measuring the total light output of a tight hi-intensity beam, the instrument is not measuring as much of the light that is there in comparison to measuring a more diffuse beam output.

Slicing the dome off reduces clarity a lot, because it is no longer a very smooth surface.

There are tests that show like 20% lumen decrease or something around there.

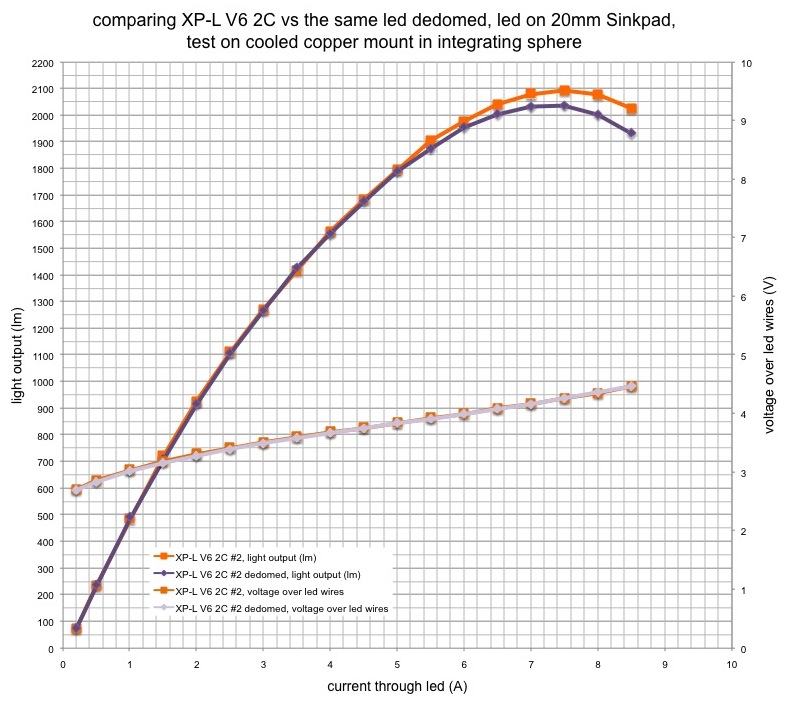

A proper dedome does not disturb the phosphor and doesn’t affect the lumen output, or at least that was the case with the older cree leds like XP-G2.

Have you read Dr-Jones explanation on de-doming?

De-Doming will always reduce the lumen output. The manufacturers put Domes on LEDs to increase the extraction of Lumens (has to do with the refractive index of silicone vs phosphor). So removing it reduces the Lumens.

Seems you're having problems with the newer gen Cree emitters plus crude dedoming methods.

Have you tried fuel immersion baths while high current driving the emitter? This was said to be the best recipe for dedoming, leaving an intact crust of phosphor layer over the die and doing away with all of the dome remainings. Or so they say. ![]()

Cheers ^:)

Not as significantly as dome shaving, if the dedome is done well.

I can’t find the shaved dome comparison image ![]()

Just thought in would add this info, put a dedomed 90cri 3000k xpg3 in the m2 and it’s now 34200ish cd. Big jump over the sliced xml2 in it previously. Reading 5.5A at the tail cap so from djozz’s test is guess at around 1300lm.

Hmmm. Dome-on, dedomed, sliced, HI, DD + LED Seal… Anyone ever compare all these methods to see how the LEDs fare?

If sliced preserves the phosphor→silicone boundary to let more photons escape, I’m kinda really surprised it’s not as good as fully dedoming it.

So I’ve been screwing around with slicing various LED’s and decided to see what happens when I stick a sliced 219b in the TN4A, the answer: 47kcd. Not to bad really when compared to the XPL hi that was in there. It does lose almost all spill but the hotspot becomes about 2/3 the size and stays (visually) almost as intense.

I’ve been playing with XHP50.2 recently. I’ve learnt the slicing must be in 2-3 stages to avoid crushing the edge at the end of slice.

Unfortunately I did something wrong. I was stunned to see a donut hole appearing as I’m staring into hotspot. I thought it was a blinding effect untill I saw the LED.

Since I’m always trying to learn on my mistakes, I’m actually wondering which of the below I might commit. Can you please advice what was the reason in your opinion?

It happened when I sliced XHP50.2 in my FT03. I’m quite sure I did not dig into phosphor layer, slice was 1 - 1,5 mm above it. But the top surface after slicing was not very even. I was sanding it (2000 grit wet sand paper) but I did not finish, I just wanted to check how does some uneven places are visible in the pattern.

The reasons I take into account are:

- uneven top surface

- missed crack in dome reaching phosphor layer

This is the pic:

Try to clear the burnt surface and check if led is still working at the spot.

I faced the same with an xhp70.2, cleared it and sliced dome a little nit more, it is still working.

It’s burnt to the ground, the black residue was falling out of the LED. But it was working, however the donut hole was ridicolous.

Anyway, I just threw it away. I want to avoid the same error again, that’s why I’m investigating the reasons.