Finally got around to finishing this small fixed blade, referring to it as my L’il Bug. .160” stock in 63RC MagnaCut, 3” long. Purple G10 scales with Orange G10 liners and pins. Orange and navy blue mesh print Kydex sheath for pocket carry. UlTiclip is help up by the ice storm.

Beautiful lines on that blade and grip. Thanks for the awesome photos.

“Honey, I shrunk the Chef’s Knife” ![]()

Thanks Jon. Appreciate that.

When I started making blades, on oxygen recovering from Covid, I set out to draw up a perfect fit to my hand. The arch across the top appealed, as did finger grooves and a safe guard. I finally made a 5” wood handled MagnaCut for my EDC and this lil guy is a compliment to it, same basic design in a pocket size.

No idea really, at this point, if I’ll adjust to a pocket fixed blade, but I’ve accumulated far too many folders and really found myself still looking so I thought maybe, just maybe, a self made companion piece might do the trick. And save me money on that search for the ultimate everyday carry combo!

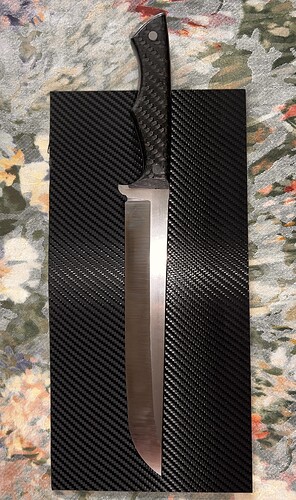

4 more in the finishing stages. ![]()

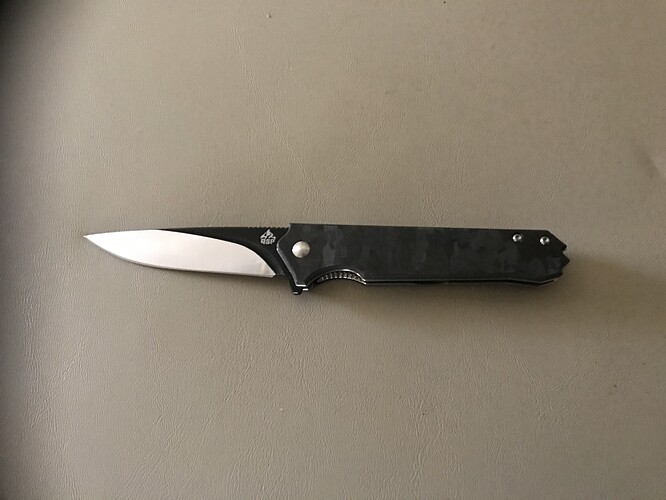

LionSteel M4 in MagnaCut:

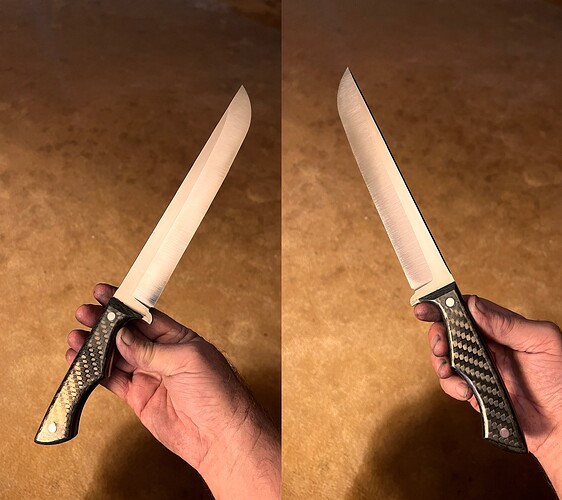

After a LOT of work, DBC No. 14… the S125V mini Katana is finally finished! Made a carbon fiber print Kydex sheath for it as well. OAL of 13.5” with an 8.25” blade, this one was hopefully the hardest one I’ll ever do! Tempered now at 63RC, looking forward to testing the legend.

Beautiful work. Thanks for the great photos.

That’s impressive!

![]()

Thanks guys, I feel good about it. Definitely a difficult steel to work. Ate drill bits and cobalt band saw blades even in it’s annealed state!

Wow, looks like it’s a mean slicer! Very nice traditional tanto shape!

Finished another knife, out of order perhaps but hey! This is DBCustom number 13. With a 5 1/2” blade in MagnaCut at 63 RC and Suriname Ironwood scales it has a 17° secondary bevel per side and is quite sharp!

Sheath is a leather print Kydex.

Polished the blade of my 13th knife, by hand… using 120-5000 grit sandpaper. When finished I honed the edge on the 5000 grit paper (yes, I sanded it sharpened!)

Very Very Sharp! ![]()

Beautiful finish!

I’m curious how you used the sandpaper to hone the edge evenly from the heel to the tip, while maintaining a consistent bevel. Did you adhere the paper to a strop, a rod, a board, etc., or just handheld with a good eye?

Also, how many grits did you use? Any of your favorite sharpening tips would be appreciated. Thanks!

From start to finish I used a technique learned from my gunsmith friend decades ago… sheet sandpaper on a flat surface. In this case, a plate of 6065 aluminum 3/4” thick.

Altogether I used 12 steps, 120-5000 grit. In the finest grits (2500 and 5000) I used a foaming glass cleaner to keep the sanded particles isolated, this wetness also adhered the paper to the aluminum.

I use diamond hones with a Lansky clamp system to sharpen my knives, finishing with a Sapphire stone. I had already sharpened this knife before I decided to polish it.

Honing at the end was done the same way I use my leather strop. ![]()

Thanks Dale for the additional details! If you don’t mind, I have a few followup questions.

-

For instance, is the aluminum plate handheld sized, so you can polish the blade with the knife handle secured in a vise, or similar? Or is it a large aluminum plate, secured flat on a work surface, so you can hold and freehand polish against the sandpaper-covered plate?

-

Do you saturate the sandpaper?

-

Is the glass cleaner a homemade solution or a product specifically designed for this purpose?

Thanks again Dale! - JC

Well, I WAS using the table on a jig saw and remember the 11x14x3/4 plate I had gotten for a reloading press to mount on. So I clamped the plate on the jigsaw table and utilized the smoother flatter surface.

I spray a liberal amount of the glass/surface cleaner such that it stays wet for the 40-50 strokes I intend to make, move over flip the blade and repeat. After about 6 such passes it was good. In part I keep the blade flat, for the coarser grits where I have grinding scratches I use just the corner to concentrate pressure.

Windex will work, any surface cleaner that is thin and readily evaporates will do. It’s primarily to help keep the ultra fine grit from clogging so quickly.

No freehand polishing on a razor sharp blade. Had I made the decision to polish it before applying the scales and before cutting in the secondary sharpening bevel it would have been much safer and easier.

Thanks for the added information. Since I don’t have a need for dedicated sharpening system such as a Lansky, I like to gather any new tips I can find to help with hand sharpening & honing.

My daily pocket blade is a Benchmade Mini Grip, which has been easy to keep sharp. Same with the kitchen knives.

I use the underside of a ceramic mug to hone those edges in-between sharpenings, which works really well.

However I’m still having a hard time getting a good edge on a few budget blades with lower/mid range steels, such as my Kershaw Cryo G10 with a 8Cr13MoV blade, and Leatherman Skeletool with 154CM. Practice, practice, practice!