Yeah you definitely want DTP if you want to get the most out of this LED.

Thermal paste is a must.

If you want to do 5-6A then you need a proper heatsink, not a flashlight host, to dissipate the heat.

Thanks Steve.

I suspect heat spreading on oslon black flat is pretty bad, bottom pads are very small so power density (W/mm2) is very high at board-pad junction, over 15Watts per 1mm2 of LED die.

This board was designed for IR oslons (black flat was still not very known at the time of design) , and it should perform much better than existing insulated boards like non-dtp copper pcb for XP, and Bergquist 804087 .

I will have two oslons flat for testing soon,after test I’ll do “autopsy”, I’m very interested in how cross section of oslon flat looks inside (thermal path specifically). Plastic case of oslons always was downside for me, I assume there is no ceramic like alumina inside, just copper pad, the question is how thick.

I did some calculation, mosx have thermal resistance equivalent to <250um of solder layer, and if I remember correctly someone did the test noctigon vs. sinkpad 2 (gap on top) ,and there were no visible difference in performance for xm-l2 and similar leds, but they have ceramic substrate and pads have decent size.

that was me, and the led was a XM-L2, so a way bigger thermal pad (13.3 mm2 vs 2.7 mm2 for the Black Flat, 5 times bigger)

It was actually this test/thread:

but I see there is identical picture in your thread also. Somehow either I missed your thread or forgot about it. Subscribed![]()

Yes, the observation is the same: with the XM-L footprint, the thickness of a solder layer under the led is not critical as long as you get rid of the thick dielectric layer. But apparently at the same powerlevel but a 5 times smaller footprint, the details of what happens under the led are more critical, makes sense ![]()

I ordered some MosX oslon boards for testing too , and i already have some Oslon black flat leds (LUW HWQP) here …

Right now i tested one at a Thorfire C8S on a DTP board (without a driver) , with AR glass and i get otf 720 lumens & (only) 170kcd @ 5 amps , using sony VTC5 .

720 lumen (@30seconds?) sounds really consistent with my Supwildfire driver-less thrower (350kcd ![]()

![]() ) which is 700 lumen but does not have and AR lens.

) which is 700 lumen but does not have and AR lens.

Yes , about 25 seconds after turn on .

Focus seems good , now i use a 0.3-0.5mm centering ring , i don’t think i can get a better focus for better results …

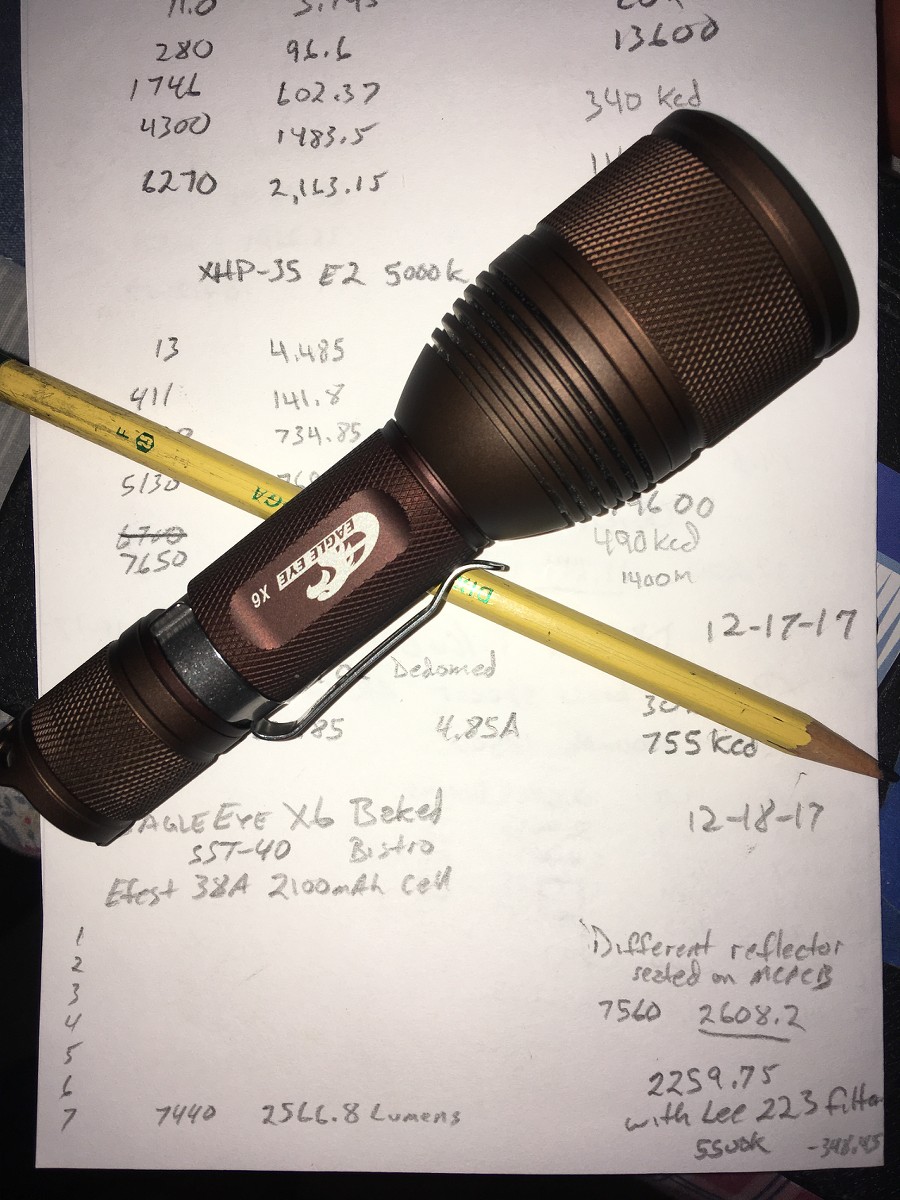

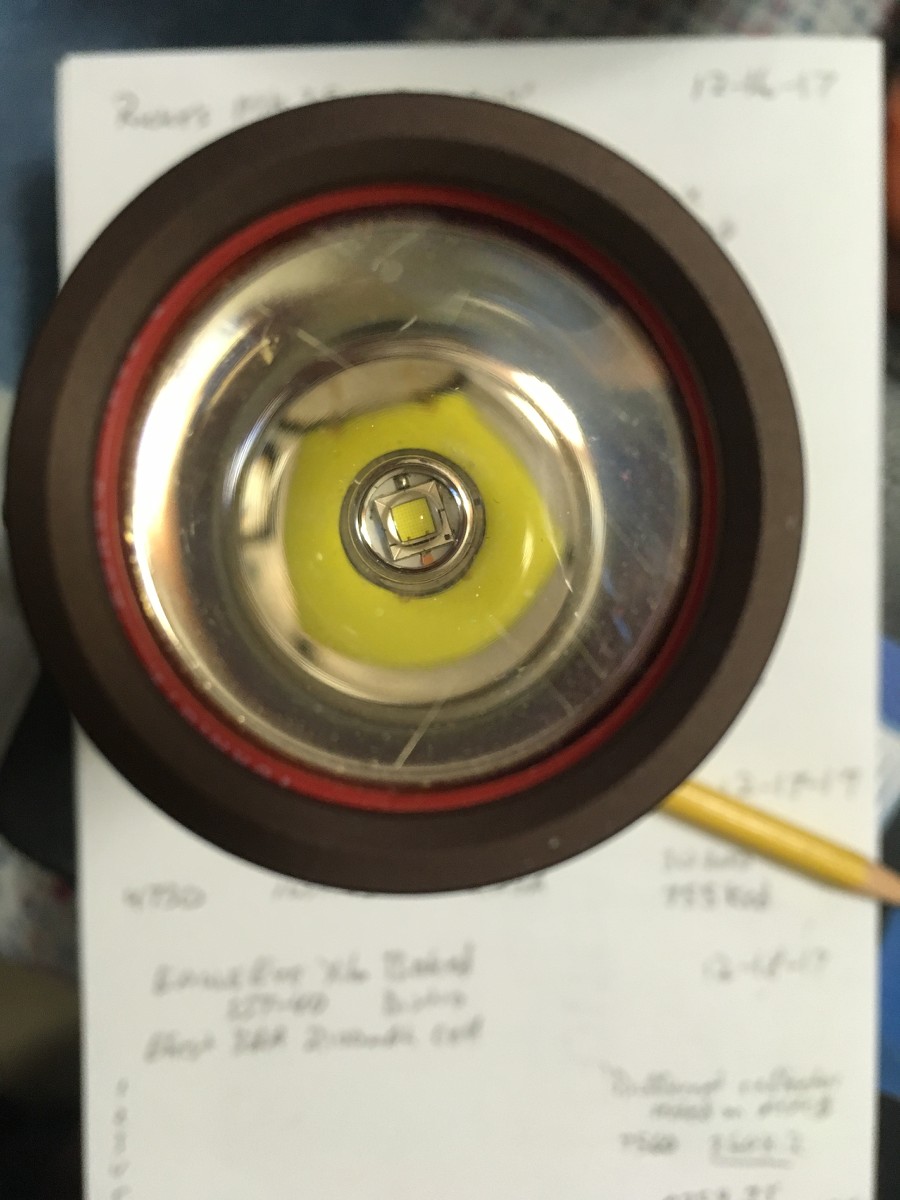

Stuck one of the Luminus SST-40 emitters on a 20mm SinkPAD and put it in a baked Eagle Eye X6 with a Bistro driver. On a 38A 2100mAh Efest it makes 2601 lumens out the front. I don’t really care for the blue tint side of things so I cut a piece of 223 Lee Filter and put it on top of the AR coated UCLp lens. Now I have a 5500K tint but with a 14% loss to around 2200 lumens. Looks good though, nice spot with an aura and then a useable spill.

Nice, they state these are 97% throughput but even after adding the lee filter it’s still at 86% so it’s worth it. You won’t get 2200 lumens out of a similar tint XM-L2.

That’s what finally dawned on me, reducing a 1A to a 3C is going to cost lumens output in a similar fashion anyway, and the SST-40 has a higher launch to begin with so it’s still a win.

This is what they call one eighth O.T.C. (Orange Temperature Color) and has an 85.2% transmittance with 7% absorption rate. You can see on the bottom right corner where I wrote down the lumens before and after, seems it was pretty spot on. ![]()

I simply looked at a color wheel and chose the opposite of the daylight white blue-white color I was seeing in the output, which is a light orange. Then went through the Lee filters to find the correct shade of orange and it works great. So far, anyway. I’ve melted more than a few of these pieces of film and this one doesn’t seem to have a fire retardant counterpart.

Very cool, let us know if it melts, but if it doesn’t it’s a good solution for sure. I’ve used a similar film when making lanterns from scratch before. I’ve also used one with diffusion to take the doughnut hole out of the XHP series.

Did the last days a couple of driver designs

Q8 2S/4S Buck driver

6/12V LED 2.5-5A standard parts

6-8A with upgraded parts

Astrolux MF02 same specs as Q8

TN42 driver same specs as Q8 and MF02

Oslon Black flat

DTP friendly P channel MOSFET driver

17mm and bigger

did 17mm Oshpark

and 17-24mm Seeed design

Nice work Lexel :+1: :heart_eyes:

I wasn’t happy with the XHP50 in the MBI HF-R so installed an MT-G2 on a 16mm Noctigon sanded down to 12mm with 1mm copper sheet soldered underneath.

That looks great! The MT-G2 is one of the prettiest leds ever made, and in a build like this that counts more than performance.

Thanks djozz, yeah that’s what I think, I just love the MT-G2 ![]()

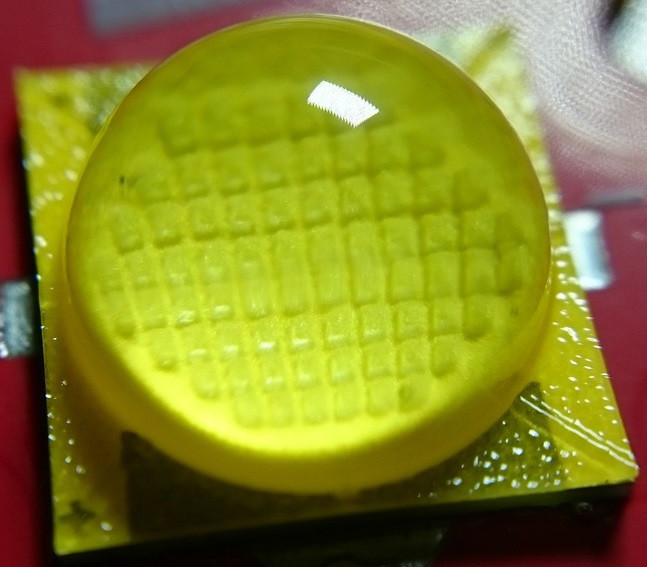

My favourite pic of MT-G2 in my Small sun ZY-T08 :heart_eyes:

Wow, you keep your domes clean! :+1: ![]()