I changed the lens in 2 Convoys this evening.

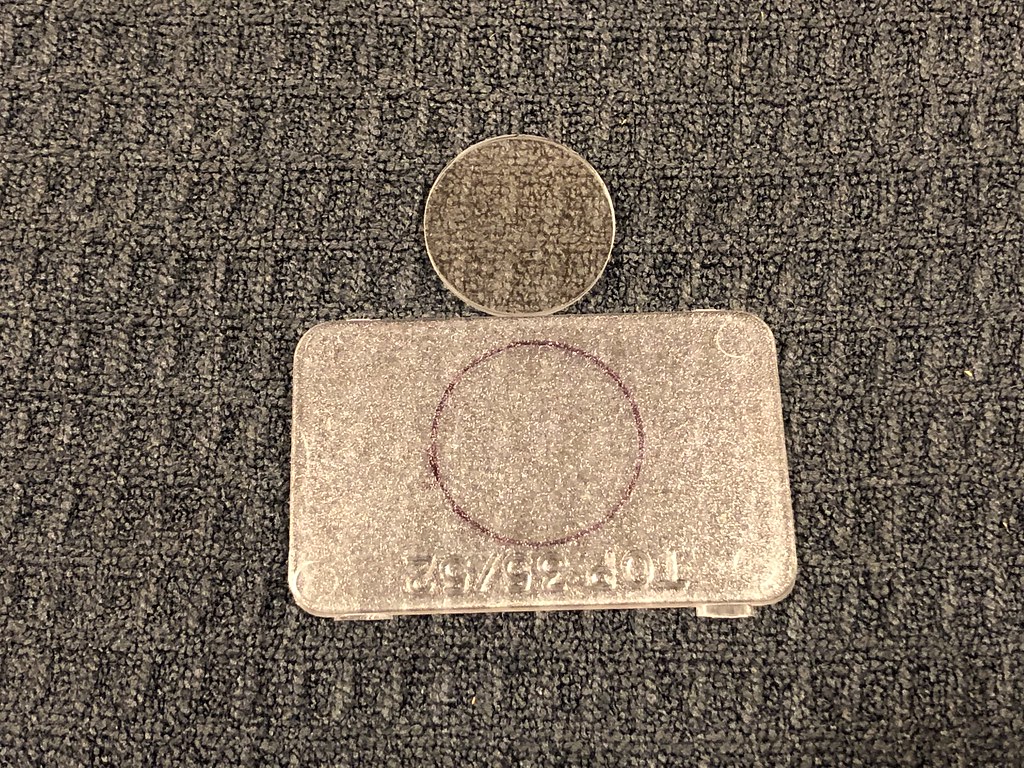

First was my S3. It has a CREE XM-L2 4250-4500K LED and an AR lens. The beam was not the best with lots of artifacts and a greenish ring. I didn’t use it much, except for outside. I tried switching to a non-AR lens and a different reflector, but the beam was not much better. Then I decided to make a diffused lens from some acrylic spacers that I kept from a storage container:

What a huge difference that made! No artifacts and I even see some rosiness now.

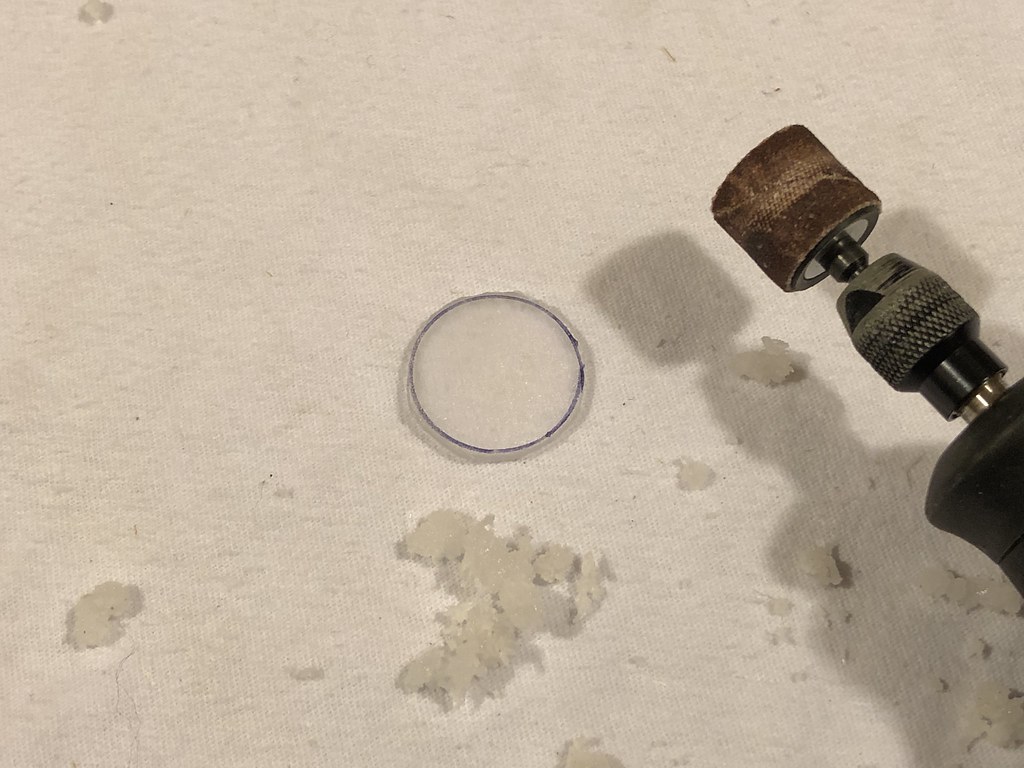

Second was my S2+ clear (silver) with a Samsung LH351D 4000K 90+ CRI LED. I’ve worked on it before to clean up the beam with a different reflector, but it still had some artifacts. So I replaced the non-AR lens with the same acrylic lens and it made a big improvement, but made the beam too diffused. So I took the AR lens from the S3 and sanded one side with 60 grit sandpaper. That turned out to be perfect - no artifacts, but still had some throw.

Left S2+, right S3:

Sure I know I’ve lost some lumens doing to this, but it’s worth it to me to have great beams! And after all, these are EDCs, so the emphasis on beams is more important than lumens.