I imagine most everyone has seen this type of light.

The photo is linked to the seller for more pics.

The photo is linked to the seller for more pics.

I have too and I have always wanted to make one, but it has always seemed too hard. I finally gave in and I am trying this on a Mini-Mag.

It's a 2AA Incan Mini-Mag. I will be cutting it so that it will swivel from straight to 90 degrees. I will be using Copper pipe inside the body as the liner and swivel mechanism, since it's easy to form, solder and finish off.

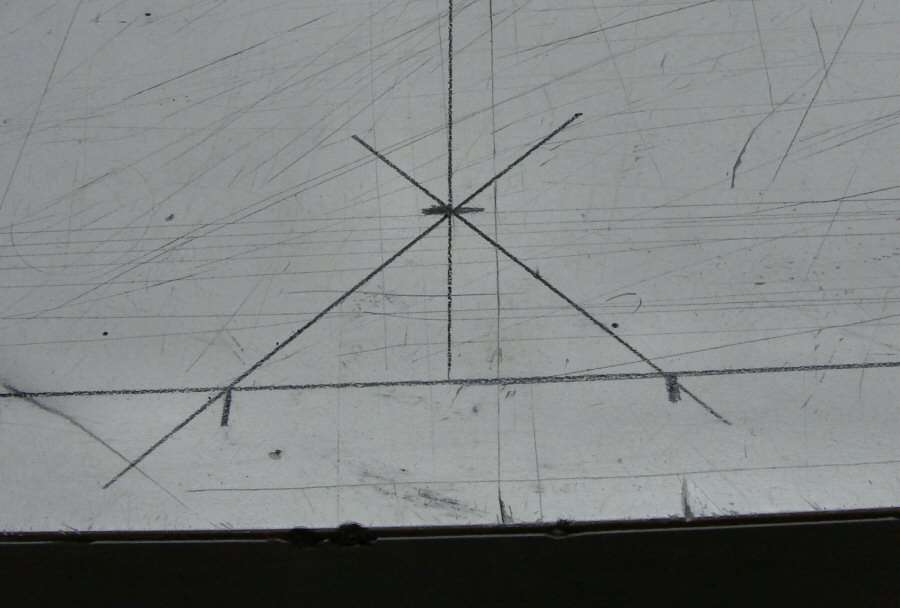

First I need to mark a true 90 degree line and I did it in pencil on my bench, with a square. Then I marked out the 45 degree lines, for a template to cut the body.

I have two pencil lines up on the body near the threads. Those are where the head is down all the way and turned up to where it will be for this mod. I am measuring how far the battery will go in, so I can mark that and then make my cut somewhere between the marks.

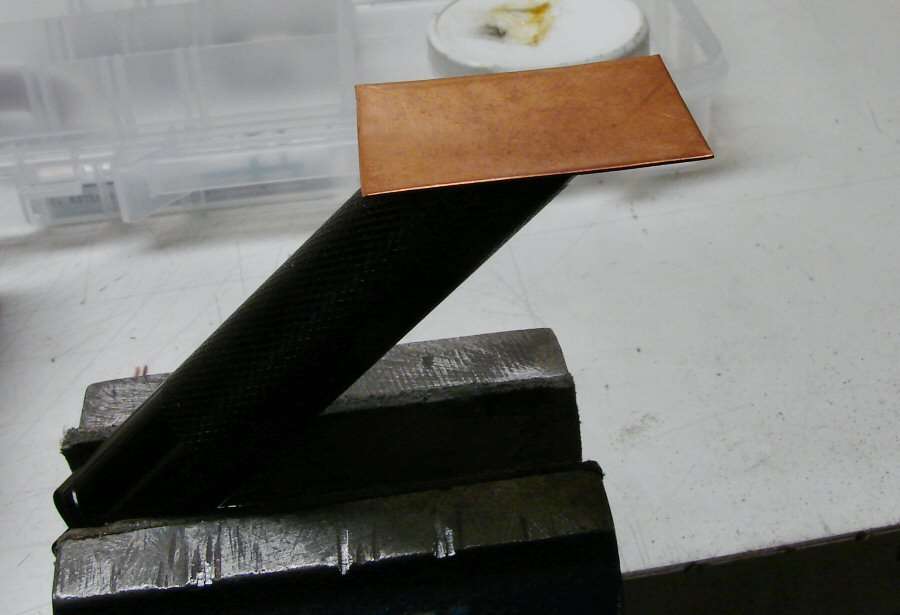

I have clamped down the body and then I am ready to cut. The small square is there to help keep me from cutting on an angle as I make the 45 degree cut on the body.

The cut is done and you notice below that it's not a true 90. I can work on that by sanding the mating surfaces on a sanding block, to get the match closer to a perfect 90.

I start with 120 grit and then move on to 320 grit. I am just getting the fine tuning done, so the ends match tightly.

Now I need to figure out the OAL for my Copper pipe. I have to leave room at the ends, for contacts, so I cut it a little shorter than I want and by the time I make the 45 degree cut, it will be about the right length.

But, I can't put the Copper pipe in the body, it's too big! So I have to split it lengthwise.

Then it's still too big, so I have to start shaving off a little at a time, till it is a tight fit inside the body.

Like I said, a little at a time. It's time consuming, but that's hand work for ya.

I also have to heat the Copper up and make it soft, so it will form to the smaller ID od the light body. I heat till it turns black when it cools.

That's pretty good and I am using a diamond file to dress off the edges. When all is said and done, this pipe will be cut at a 45 degree angle, like the body and soldered at the seams to make it strong again.

Now you notice my knurling does not match any more, because of the cut, so I will have to make a spacer of some kind, but that works well for this swivel, because I will solder flat Copper on each end of the pipe, where the body goes together, so I can connect the two ends and the thickness of the flat copper will space out the body.

I have the copper cut and sanded smooth to the Aluminum, so everything matches well. Then I solder the flat copper onto the pipe and solder the seam in the pipe as well. I just use my torch and heat till the solder melts. It does not hurt the color of the light if I just heat till the 60/40 solder melts.

Here's the pieces soldered and I need to do a lot of clean up on them. I will be cutting the flat pieces, so that when it's back together, they will be the same OD as the body, for a smooth line the whole length.

More when I get more done.......

-----------------------------------------------------------------------------------------------------

02-25-14

I finally decided on how to hold the two pieces together and put the positive wire thru, at the same time.

A brass screw and nut, with a hole drilled in the center of the screw. I haven't cleaned the hole out yet in this shot.

The Copper body inserts are shaped and drilled for the screw.

This is how it might look when it is done, if I can figure how to tighten the screw, so the two pieces are snug, but not too snug, while keeping the screw to loosen. Once I figure that out, I'm home free, Right?

I ended up using JB Weld on both ends of the screw, to fill up the ends and once it hardens, it should work fine.

----------------------------------------------------------------------------------------------------------------------------------

Well, it's time to call it quits on this light. Maybe someday I will find a good way of attaching the two sections, but not this time around and once I reach a certain point, it's dumpster man time. I take a certain amount of pleasure, bitter/sweet, in throwing a project out, that has caused many headaches. Anyhow, it's not to be this time, maybe some day. What I need is to find a hollow rivet that is no more than 3/16" outer diameter, to have any room left for some type of detent to stop the swing at 90 degrees. It's another case of ten pounds of ---- in a five pound box.

I couldn't stand it, so I had to try again.

I bought a blue light and started all over again. Here you can see the copper insert already made. I ended up using a 1/8" diameter pop rivet with a washer on each side and I took out the center of it for the wire hole. I still had one of the copper pills left from about a year ago, so I used it and used an XM-L2 on a copper star. The plastic bushings are to keep the positive contacts from touching anything and the TIR optic is what I generally go with on these mods.

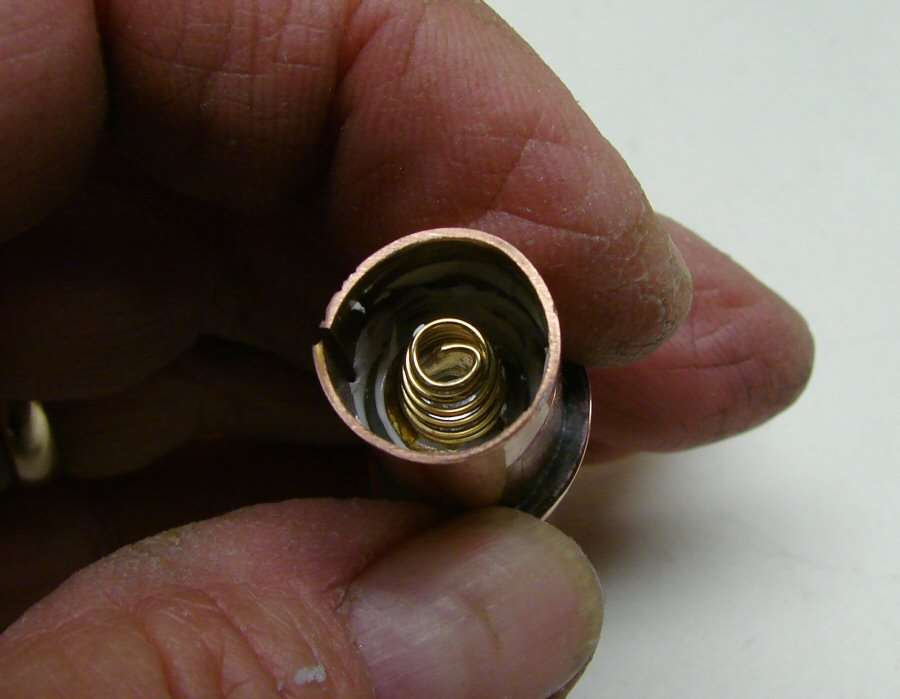

This is the battery terminal end. A copper disc, a spring, plastic bushing inside.

Here's the other end that goes to the head. Spring and plastic bushing. I used Fujik to hold things in place.

The pill is in place. and the positive is isolated by the plastic bushing, with the terminal on the end.

I used AA to hold the star on. The negative just grounds right to the pill.

The ano is removed from the end of the body, so it will make contact with the pill.

15 degree TIR optic.

Both halves of the body have a brass pin through, to hold everything together.

Well, at least it works. Not real happy, but it got finished and it works.

I will do a couple of beam shots tonight. This uses one 14500 and it's DD. The XM-L2 is cool white.

-------------------------------------------------------------------------------------------------------------------

It's running about 1.4 amps DD with an efest 14500.

That's all folks...