INTRODUCTION

The SyniosBeam skybeam is a high efficiency LED-based searchlight using a new design completely different from the previous two searchlights, the LightCannon and the OptoFire. This design consists of a backwards-firing Osram Synios LED combined with an 11 inch diameter precision reflector. With the higher intensity LED, redesigned optical system, and better cooling, this light is expected to surpass 12 million candela, the intensity of the very popular Maxabeam military searchlight. Extensive research and testing has led to a design that looks very different from a typical flashlight, however the portability and battery power will still classsify this searchlight as a flashlight, potentially making this the world’s farthest throwing LED flashlight if the expected performance is achieved.

WHY A THIRD VERSION?

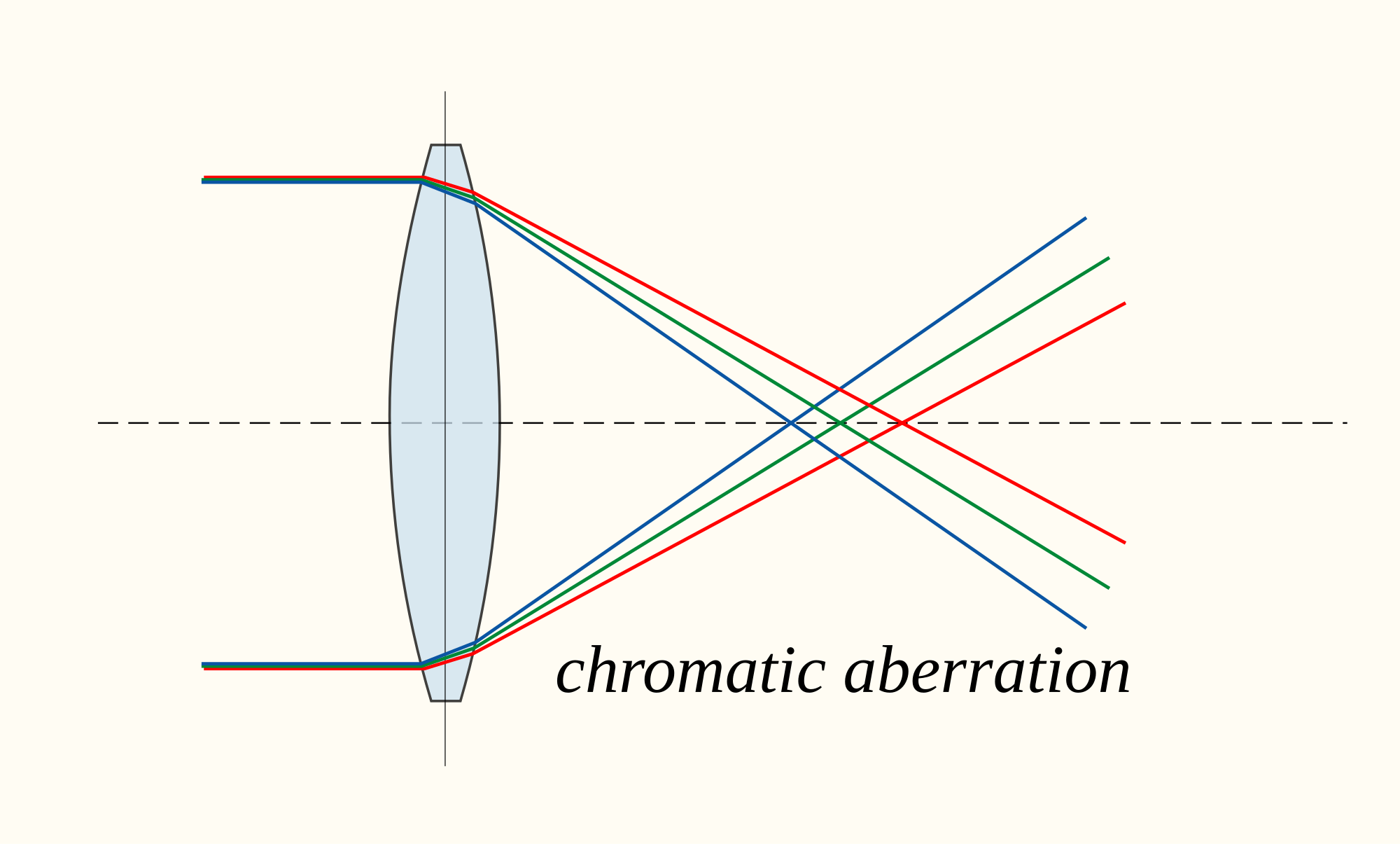

This is the third long-distance LED searchlight that I am building, so you may be wondering what was not good enough in the first two. Here I will explain my reasoning. First of all, a large flaw of the previous designs was found when doing some beam collimation testing. When a template was placed in front of the light with small holes in it, it became very obvious how much chromatic aberration was occurring. Not only does this make the projected spot appear ugly, but the separation of colours could also be affecting the overall intensity of the beam. With some wavelengths bending more than others, it is possible that some light is missing the hotspot altogether and being wasted. This is a natural properly of the refraction of the glass, and even though (very expensive) options exist to counteract this, such as achromatic lenses, there will always be some difference between the angle of the red and blue wavelengths exiting the flashlight. The best solution for this problem is to use mirrors instead of lenses, since reflecting light will not cause any achromatic aberrations.

Another issue with the previous two designs is that it is difficult to continue improving them by using larger lenses. The 120mm OptoLife lenses found for the OptoFire project were the largest stocked aspherical lenses I could find on the market. To increase the candela further by using larger lenses would require custom made lenses, which would cost thousands of dollars rather than the tens or hundreds of dollars that stocked lenses cost. Not only that, but as the lenses need to be made of glass and are very thick, the weight would increase exponentially with larger diameters. This means that using large diameter lenses is both financially and practically unfeasible. The third issue with the previous aspheric lens designs is that the small light collection angle from the use of a lens means only a fraction of the LED’s luminous flux gets used and output by the flashlight. Even with a light recycling Wavien collar, only about 25% of light gets collimated into the beam. This means that the overall efficiency is much lower, and the lumens projected onto the targer are very low. The final problem is again to do with the use of lenses. When a lens is manufactured, not all of the front area is properly aspherized. Lenses will have a “clear aperture” specification stating what percentage of the diameter is actually properly machined and useful. Even if the lens is 90% or 95% clear aperture, there is still optic diameter being wasted, making the head of the flashlight larger than necessary and some light will not be properly collimated into the beam. On top of that, the surface for an aspheric lens is very complex to machine due to the equation that defines its slope. This means that to get a high quality asphere that collimates light very well, expensive machines and manufacturing processes need to be used, adding to the cost. Getting a perfect asphere on a lens is near impossible.

![]()

These are most of the down sides of the previous two designs, and the main reasons why I will be using a parabolic reflector for this next prototype. Below is a detailed comparison of six different light collimation methods considered for this project. Multiple-lens assemblies were omitted because they do not increase the candela over a single lens setup, they only increase the amount of lumens collected, which would make using a Wavien collar not an option.

Other than two down sides, no option for a Wavien collar and less spot sharpness, the rear-facing LED and parabolic reflector is clearly the best option for a large-diameter searchlight. Even though the first two have gotten very high candela, there is always a way to increase the numbers. The larger optic diameter, better LED, better cooling, the use of a reflector instead of a lens, and an overall better design makes me confident that this third prototype will surpass the previous two by huge amounts.

TABLE OF CONTENTS

1) Introduction - Pg.1

2) Why a Third Version? - Pg.1

3) Real World Applications - Pg.1

4) Theoretical Intensity and Other Specifications - Pg.1

5) Parts List - Pg.1

6) Budget - Pg.1

7) Prototype Revisions - Pg.2

8) Renders - Pg.2

9) Build Process - Pg.3

—— the reflectors

—— the waterblocks

—— waterjetting

—— electronics

—— more electronics

—— chassis

—— chassis finished

—— liquid cooling and first test

—— AR lens and outdoor beamshots

—— anodizing finished

—— initial testing

—— final assembly

10) Finished product pictures - Pg.7

11) Beamshots - Pg.7

12) Performance Results - Pg.9

13) CFT90 upgrade - Pg.12

14) Conclusion - Pg.12