Awesome!!!

Been talking about li-ion shipping issues to Brazil recently: Living a lithium hell by JudgeDredd.

In conclusion, best bet for getting good cells there looks to be the Sunway Store (really affordable 2pcs/lot packs of INR26650-50A cells).

WarHawk-AVG (and all of you) fellows, could you cut back the quotes a bit? I find it somewhat cluttering (as nearly always on mobile). There was some funny quote related thread sometime ago started by some complainer, didn't subscribed and no idea of what happened to it. As you may guess, at some point it started to look ![]() insanely cluttered, though.

insanely cluttered, though. ![]()

Cheers :-)

Thanks for the answer, Barkuti and WarHawk (again). It's, in some way, good to know I'm not suffering alone (in Brazil as in the Canada, like JudgeDreed). This time I got lucky: a friend of mine is coming from Europe and will bring me some LG INR 18650HG2 (the chocolate colored one). Is good for a while but I'd like to obtain these batteries in my country... I saw the people uses these batteries for flashlights but also to... smoke. Let's wait...

The suggestion to use MT3608-based device to raise the voltage from 18650 batteries was realy useful: the XL6009-based one, despiste of the specs page says (https://www.sunrom.com/p/step-up-dc-dc-based-on-xl6009), don't worked fine with 3.2v (2 AA-type batteries). It worked fine with 4.7v (3 AA-type absolute new) and, as I set the micro-pot to obtain 5.25v, it worked fine. But when the voltage droped to 3.2v (only 2 AA-type), I surprinsingly got more than 19v as output! In other word, I guesse XL6009 became crazy! I got imagining the player, wich supports 5v, being feed with 19v! Testing is everything... I wrote to manufacturer telling this story. Let's see...

Thanks again for the help! And I'll post the next steps, if it don't boring you. ![]()

MT3608 integrated booster supports “2 to 24V” input voltage range, this makes it capable of being fed with “2 × alkaline/Ni-MH” voltage range input for as long as battery load is kept low enough. Alkaline cells have very high internal resistance, discharging them above ≈0.1C rate starts being noticeable in delivered capacity and energy.

For li-ion (2.5 - 4.2V) to ≈5.5V output voltage the MT3608 should deliver great conversion efficiency. ![]()

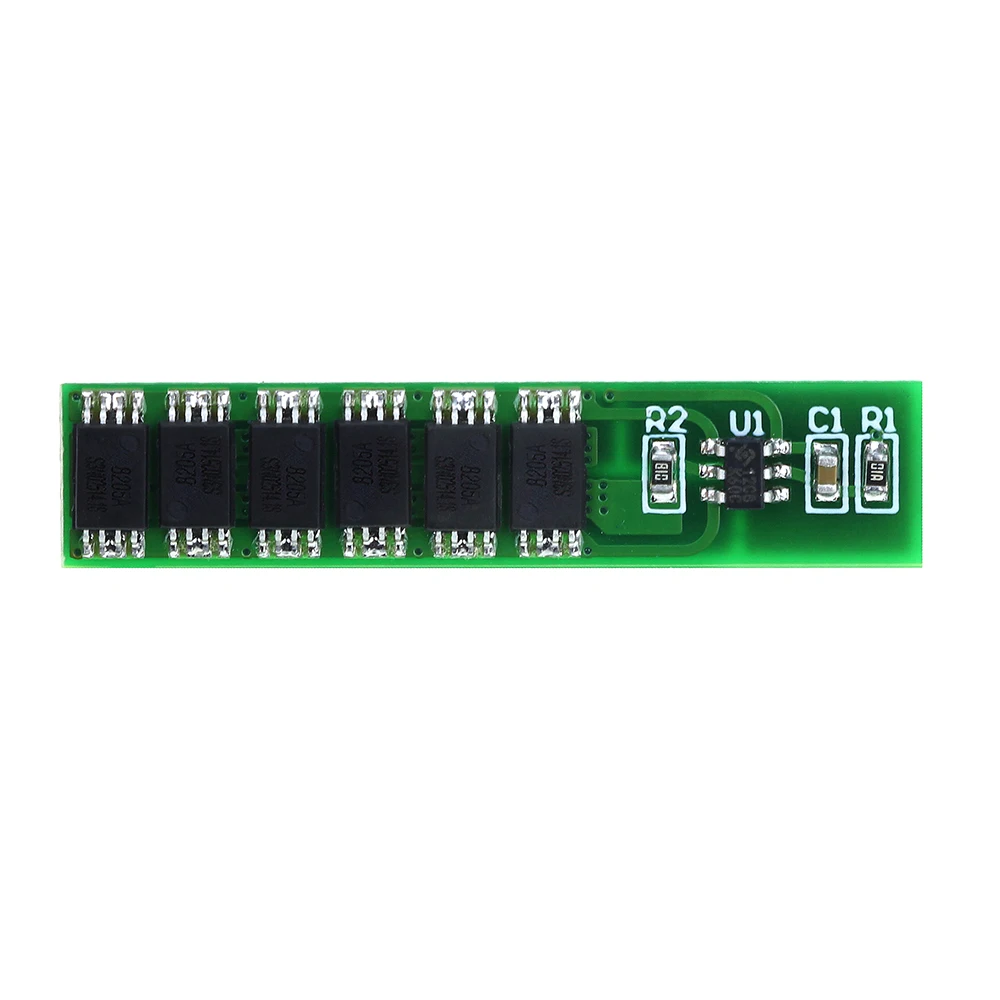

There are some nice and inexpensive 1S BMS boards for DIY projects:

Cheers ![]()

The MT3608-based step-up arrives, I’ve tested today and it works fine from 2v. It’s good as the low quality batteries I have now could fail and, as I said, if the voltage from the batteries drops to 3v, XL6009-based step-up goes crazy and increase the voltage to more than 19v. Even when the good quality LG batteries arrives, It’s good to mantain a room, just in case.

You post put me in doubt: to charge the batteries I’m using 2 TP4056, both with 8206A MOSFET, 1 for each battery, as I said in the above schematic. It seems to work fine. Sometimes one battery needs to be recharged then this battery’s TP4056 red led turns on for few moments but soon it get off and blue light back. I guess, even the batteries is joined after the step-up, that it’s because the batteries quality.

But my doubt is: isn’t it redundance using TP4056 with 8206A MOSFET and a BMS board? Or maybe you said to completely rip off the TP4650 and to use the BMS board intead? I don’t know this BMS but I beleive it hasn’t indicator leds, for one to know when bettery is charging or when it’s charged. I know these LED are insuficient information but it’s better than nothing, I think. (The ideal is a LED or something like, to indicate how full charged (or empty) the batteries are. Do you know something like that? If exits something like that, I could use these BMS board instead of the TP4056… If I’m not boring you, what you think?

rmlazzari, the problem with TP4056 modules is they're designed for a final charging voltage of 4.2V. This lets you attain maximum capacity from the cells but will slowly and progressively damage them. For long life cycle reducing this voltage is advised.

If you'd like some battery capacity indicator the ICGOGOGO Store has lots (here is a beautiful, cheap and good one).

Those TP4056 boards have protection logic for a limited current and power, maybe a cautious average of ≈2.5A (≈8W) per 8205A MOSFET. If you have one cell attached to each board but they're not explicitly in parallel you're doing it wrong. Set cells and boards fully in parallel for better load distribution (all B+/P+, B- and P- contacts fully bridged).

Due to inability to control final charging voltage I wouldn't use TP4056 boards to charge the cells, but an XL4005/4015 CC/CV buck module instead. Please note that in order for XL4005/4015 modules to work in constant current mode they need at least 6V of input voltage, this requires at least another MT3608 module to boost from 5V to 6+V to feed the buck module. I'd tune buck module output voltage no higher than 3.95V. And a of course a BMS.

Cheers :-)