Why copper wire though? Does current passes through? I was wondering if I can use a paper clip! ![]()

I had it lying on my desk and with insulation it was too thick - so I stripped it :D

a paper clip might be too thin

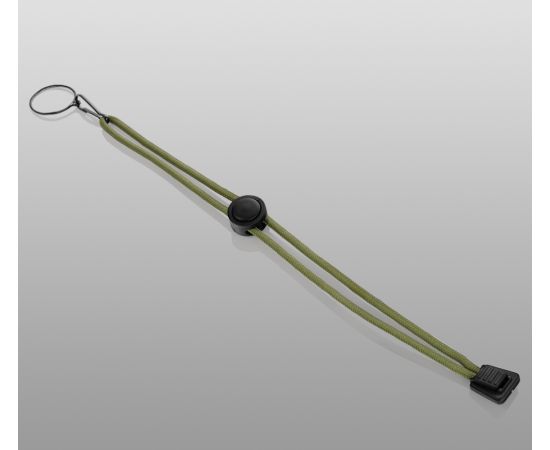

Got lucky and found a metal landyard ring that was nearly the perfect dimensions for this light. A few minutes with a sanding drum and dremel to open the ID ~1mm and here we are. Also bought some suspension clips off of ebay. I’ve been trying out this combination for a few days and it’s growing on me. Takes some getting used to for sure as it’s not the easiest to get the clip to catch without focusing on it. I’ll say that when wearing jeans that have stiffer edges and tighter openings, it’s much better. I’m sure I’d still prefer a genuine deep carry clip on days I’m using the light heavily but I just haven’t got one yet. For less frequent use, I would recommend it highly though. The light feels so much smaller in the pocket with this setup.

That pressure for the copper ring is shown starting around 5:33 in the video Max posted above.

Max, can you add the info for the rubber ring mod?

i need to find a matching ring ;)

I can take the same measurement this evening of my switch activation pressure and comparing it to a stock FW3A I have still. I’m not sure how much has changed since the original batch and v1.0 design, but note that’s what my samples are.

I’m can’t for the life of me remember what light (or other thing) that the lanyard ring came from/with. I’ll try searching the web for something similar

I’m not referring to difficulty sourcing the clip, but rather the low profile lanyard ring that goes in place of the pocket clip.

Btw, while they are cheap and work okay, the clip that you linked (and that I initially bought for testing out the idea) are really poor quality. They claim to be stainless steel but are not. In fact they aren’t steel at all. Some kind of lot melting point alloy (tin?) with a plastic coating. I naively attempted to heat color a clip and found this out pretty quickly. I’m looking to buy a USA made titanium version after I give it a week or so more trial time.

What I think the rubber/copper o-ring does, is it provides equal pressure around the perimeter of the blister switch membrane. Which requires more pressure to achieve the break-over pressure required for the switch to close.

Whereas the “nubin” concentrates the pressure at the very tip/center of the blister switch, requiring less pressure to achieve the break-over pressure needed to close the switch.

So, no.

As long as the metal ring has no sharp edge, from cleaving with a cutter, it should work like the copper ring.

But I do think the rubber o-ring would cause less abrasion on the surface of the blister switch surface membrane, than a metal ring would.

That’s my 2 cents, which is probably not even worth a penny.

Doh! Sorry, yeh I misunderstood.

Is the ring from armytek ?

That’s what I don’t know. It was a random lanyard in a plastic bag in a draw full of lanyards that happened to have that ring attached. No idea what it came from.

I asked because that’s what it looked like to me. I don’t know exactly.

This is correct. It’s a combination of force distribution and mechanical advantage that causes higher activation pressure.

Solarforce has, or used to have, lanyard rings that would probably be just slightly too small inner diameter for the FW3 tube.

The Solarforce ring works well

But you have to enlarge the inner diameter of the ring to fit which makes the ring a bit thin so you have to be careful.

Wow I like them… super nice lanyards dude!

Quick question, are LH351D emitters ok in the FW3A running un-throttled firmware? I just swapped in some new sliced LH351D emitters (noctigon mcpcb) and two of them have burnt out ![]() A bad reflow maybe?

A bad reflow maybe?

Yes they are, even using high drain batteries should be fine. Probably a bad reflow as you said. For stuff like FW3A after you mod you only want to test it without bezel on low settings to verify function. When you are ready to crank it up better have bezel tightened and if you see slightest hint of blue turn it off.

I’ve only ever killed one with a poor reflow on a Q8. Caused a chain reaction and 2 or 3 died eventually with multiple batteries of FET going into 2-3 LEDs once the first dies. It was due to not enough solder I believe.

The first one that I got (first run) I modded with LH351D 4000K’s for my wife and she has used it ever since without any issues.

Ah feels bad ![]() Everything looked good on low up to ceiling. Turbo was too much I guess.

Everything looked good on low up to ceiling. Turbo was too much I guess.

I don’t suppose a super close slice could also cause them to burn out?

When reflowing multiple sliced emitters, do you guys apply pressure to all of them as they cool? I wasn’t sure if I should do it on sliced ones.