Why not use a silicone place mat cut down?

Because the heat will pass through too easy and make your table very very hot, likely carbonising the wood. You want your heatblock hanging with as much air around it as you can.

> insulation

You might see if you can get samples of aerogel from some supplier, the stuff is used in sheets for shoe insoles, and stud isolation/heat breaks in building, and other things.

That aerogel looks really strange in pics. Amazing qualities though

@djozz

Did you get your Temp controller from ebay? Mine arrived a few days ago. Now i am still waiting for the heating elements. My Aluminium Block is 85% ready. Still have to do some grinding to reduce the thickness of the Block between the hot and cold side. But i get there in time!

Yes, I got the temp controller, but it will be a fun project with no urgency, atm the tiny heatblock of the OP just works fine for what I want. Looking forward to your version though! ![]()

Very very cool…you could get an arduino nano or mini and put a thermistor on one of the analog pins…punch out some code…have it heat to a specific temperature and voila

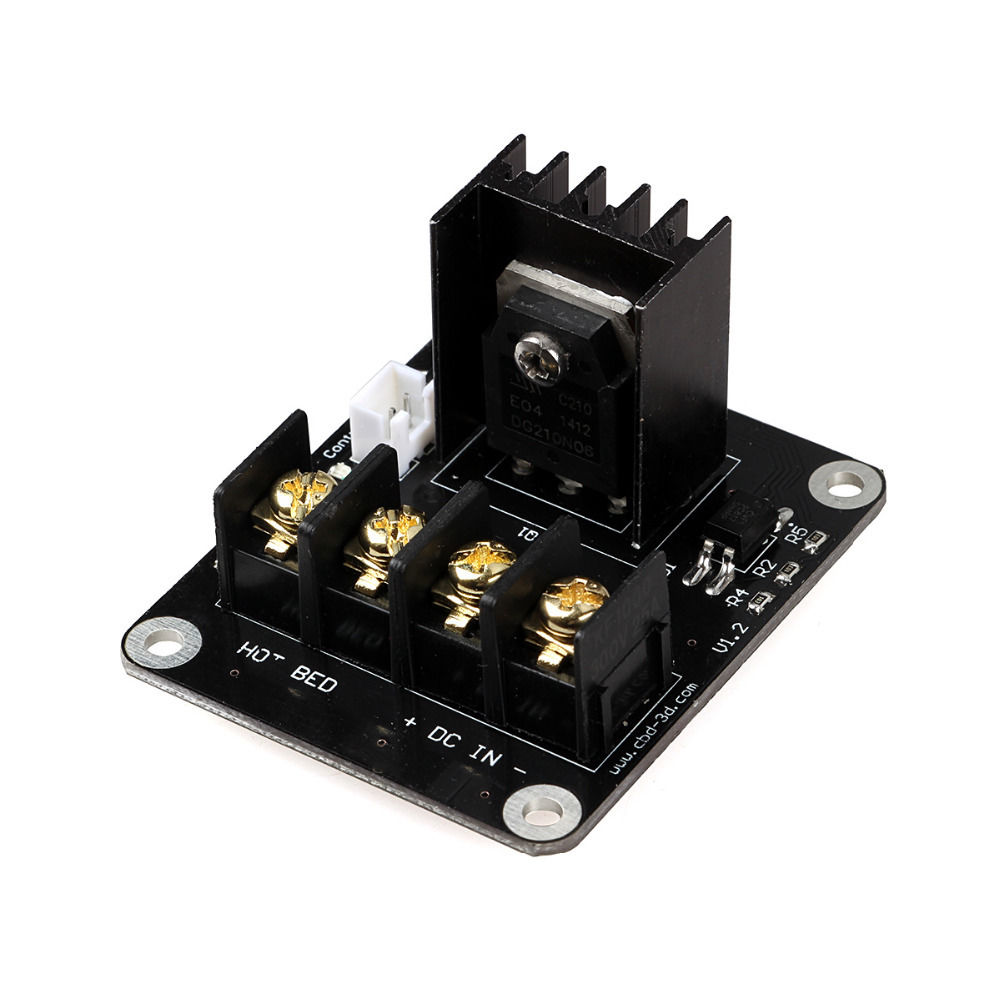

Well you might need one of those 3D printing MOSFET blocks to use the digital output of the arduino to control the heavy current needed for the heaters

Still a very very cool build using an extruder block and heat elements (they are dirt cheap)

I am using mine in my 3D printer though ![]()

Actually in this application, a relay would do their job, at lower cost

@mrheosuper

Yes this is what i thougt. And i ordered this controller for less than 8 bucks which uses a relay.

True…and at 8 bucks…no need to program or anything…just attach the thermistor and dial in the heat you want…and voila!

Good call

Did anybody else had problems with DOA heating elements. Two of my 3 elements are not pulling any Amps. And my DMM shows infinite resistance. So two are dead. Nice it has taken weeks to get them here and now i have to wait even longer. I think it would be saver to order 2 or 3 spare ones to be sure to have enough that are working. On friday i have to get to the hardware store and take a look at some things. At the moment i am not quite happy with the insulation. The Pyrogel looks nice but not the price! And i am still not 100% sure what thermal paste i will use. There are some out that will go up to 260°c but i would like to get something that can go up a little further. I found the T-99 High Temperature - Heat Transfer Compound but i do not need a Gallon ![]() . Maybee copper paste could do the job. Its made for high temps. But i do not know how well it transferes heat. I have a little bit of pure silver solder paste here (not tinn with 2-3,5% silver). Its melting point is something above 700°c and it probably will transfere heat very well, but it very pricy and would be absolut overkill

. Maybee copper paste could do the job. Its made for high temps. But i do not know how well it transferes heat. I have a little bit of pure silver solder paste here (not tinn with 2-3,5% silver). Its melting point is something above 700°c and it probably will transfere heat very well, but it very pricy and would be absolut overkill ![]() . Maybee someone know a cheaper solution.

. Maybee someone know a cheaper solution.

@WarHawk-AVG

I played a little bit with the regulator. Its nice. You still have to test out how much overshoot you will get (different with every design) so that you will not get to high temps but its nice that you can adjust the parameters for the hysterese. Only thing i did not notice earlier is, that the display shows words in Chinese. But i can live with that.

yep, out of six, one heater was dead. Should have mentioned that, but I deal with it as part of the game when your heaters are 80 cents a piece.

I must have thought of that. My fould not to order a few spare ones the first time. I will fix that also on friday. But now i have to wait again for the elements to get it done. A downer. But this will give me the time to get the housing done. Do you use any heat paste for the elements?

I greased them in with Arctic Silver 5, but I’m not entire sure if it still is ok now the heatblock has had temperatures of over 270 degC ![]() , whatever debris it forms now, still better than air I suppose

, whatever debris it forms now, still better than air I suppose

I think I mentioned previously, but I just used a set screw to provide pressure, less messy than thermal paste, and probably equally (possibly more?) effective.

Or both ![]()

I admit I was lazy with the block of the OP, my previous heatblock that I made several years ago had such a screw.

The cheap “”12V” power supply I got from BG

doesn’t reach 12V, output tops out just over 10V

What’s the next likely 12V supply to try? suggestions welcome.

I know the basic principle, “buy them all …”

Where does that 8V controller pictured above come from?

you probably need something that can push more than 2-4A….heaters even 40W can pull alot of current…

best ones to get are the uber cheap 12V 20A ones they use for 3D printers

https://www.amazon.com/SUPERNIGHT-Universal-Regulated-Switching-Transceiver/dp/B01LATMSGS/ref=sr_1_1?ie=UTF8&qid=1490738047&sr=8-1-spons&keywords=12v+power+supply+3d+printer&psc=1

Even better would be to get a 24V one (if the heater module can handle it) I built one of those Hakku DIY soldering iron w/ a 24V 5A and it heats up faster than I can dial the knob

I wrapped several layers of kapton tape around the heat block on my 3D printer…around the circumference of the block, holding in the heater module and the thermistor this way it holds them in even though the print head is going back and forth constantly