Well you definitely got me beat.

.

.

.

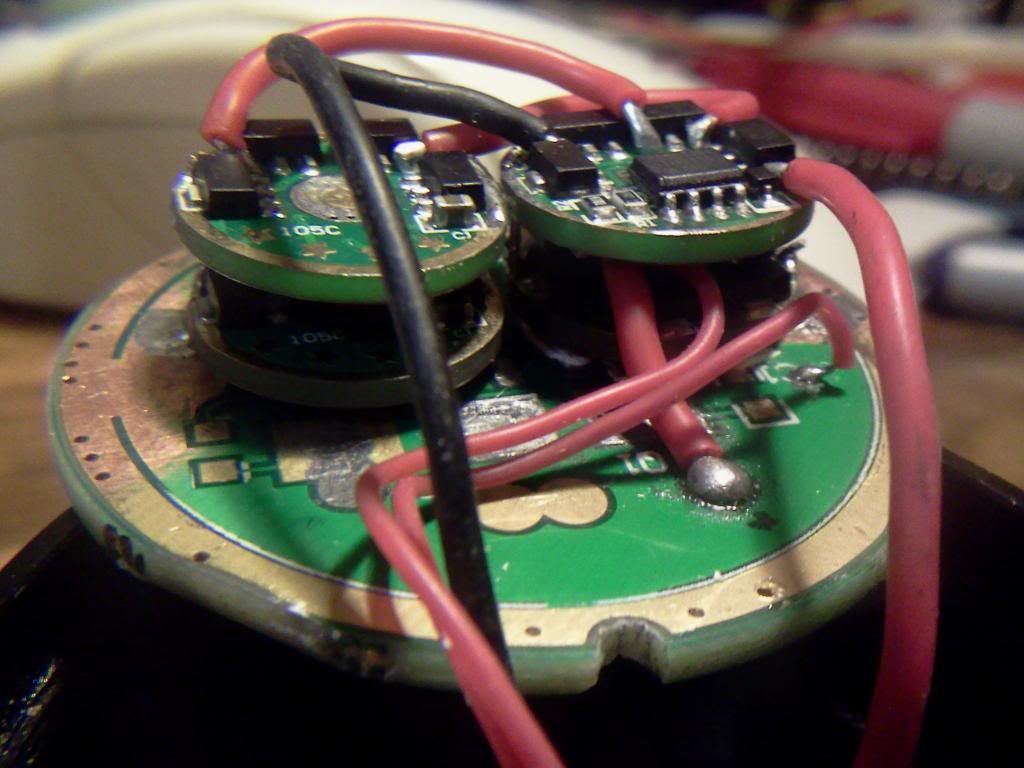

Nice job LinusHofmann. I feel your pain ![]() Mine’s only running 4 amc7135 2800mah drivers. Should give 11200ma, but only does a little over 10amps in a 4-xm-l kung using Panasonic 2900’s laptop pulls. Really didn’t take as long as I had thought it would to throw these boards together. Thanks for sharing and great mod.

Mine’s only running 4 amc7135 2800mah drivers. Should give 11200ma, but only does a little over 10amps in a 4-xm-l kung using Panasonic 2900’s laptop pulls. Really didn’t take as long as I had thought it would to throw these boards together. Thanks for sharing and great mod.

Oh cool, and that’s running the electronic switch similar to the SRK right? I assume you had to flash some custom firmware to get it to work right with these drivers. I should probably read up on how all that electronic switch stuff works, could come in handy for sure!

007, please share the juicy details of your setup. ![]()

Great mod and work!

Sounds like you made an awesome light.

:beer:

There’s a little more detail in this thread.

Great build. Of course, we still need beam shots.

Of course, we still need beam shots.

Working on it ![]()

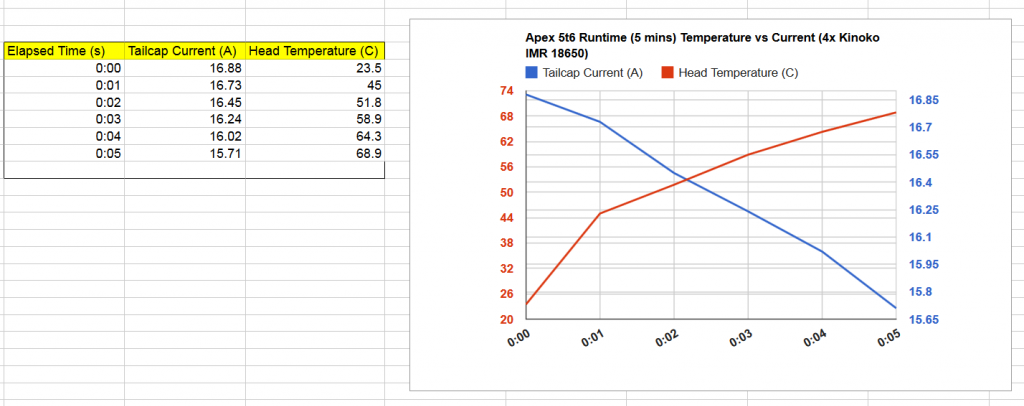

OK so today I received 3 more of the Kinoko IMR 18650s from IlluminationSupply and I thought I’d do a quick runtime test on the Apex to see just how toasty it gets when driven by some stout IMR cells.

I was also keen to see if my driver heatsinking would be adequate over an extended period on full or if I would see some throttling back of the current from the 7135 chips as they get too hot.

Incidentally the Kinoko cells have an internal resistance of between 85-95milliOhm which seems pretty good to me, in comparison my year old Protected Senybors (2400mah) are up around 155-170 each and the Protected Trustfire Flames that I’ve tested are also in that range. Tested on my iCharger306B with relatively long and sloppy leads so take them only as comparative figures.

So anyway here are the results.

–4 freshly charged Kinoko IMRs reading 4.22v each

-Run on high with IR temperature readings taken at the head every minute.

-No fan or air movement of any kind, flashlight lying on it’s side (didn’t want to risk burning a hole through my desk :P)

-Tailcap current readings taken with my trusty Turnigy Wattmeter with 12Awg leads soldered directly to the switch tab solder points (see above for a picture of the test setup)

I called it a day at 5mins because with temps still rising steadily and close to 70C at the head I started to get a little nervous! Didn’t want a runaway meltdown scenario! ![]()

That said the temperature reading of the body was obviously at a lower level, inside the battery compartment taken from the driver PCB was at a safer 45C and the batteries themselves came out of the flashlight at 47.5C.

In terms of the output stability and how these batteries performed I’m really impressed.

The current readings where much more stable than I was expecting and didn’t exhibit anywhere near the sagginess of my Senybor or Trustfire Flames. Seems ~4A per cell for these IMRs is cruising speed ![]()

I also don’t think the steady drop in current as seen has anything to do with 7135 chips overheating and throttling back so that’s reassuring. It all looks to me like solid battery performance with an expected gradual drop.

Conclusion is this light loves IMR cells, and can safely(ish) be run on high for <5min bursts. Again outside at night with cooler ambient it’s a different story and should stabilize at a lower temperature. Plus the handle makes holding the light at high temperatures fine although it’s easy to forget and accidentally touch the head with your index finger for a nasty surprise!

Thoughts welcome but I think I’ve achieved the aim of making both a camping light and heating stove all in one! ![]()

Hopefully I can get some beam shot comparisons done tonight.

Linus

Thanks for the graphs. Looks like those cells experience very little sag.

I didn't even know there was a Rules Committee.

That's great work.

Thanks Linus. Terrific work. You made me smile as your chart to me appears to make your light 68.9 degrees after 5 seconds.

haha yes it does look like that, should have used a better time format ![]()

And it’s not temperature VS current either rather it should read temperature and current vs runtime.

Ah well… next graph will be better :bigsmile:

Cheers

Well I thought I would leave the light as it is now and call it done….but…there’s really one more thing I should be doing…I think.

The problem is something I’ve noticed since I had the torch and it is that one particular emitter always seems to be brighter than all the others.

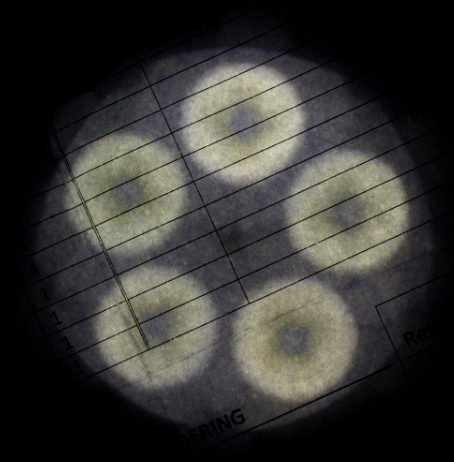

Here is a shot of the emitters shining through a white piece of paper that shows the difference in luminance quite clearly. It’s also interesting how you can see the tint variation of the different emitters like this.

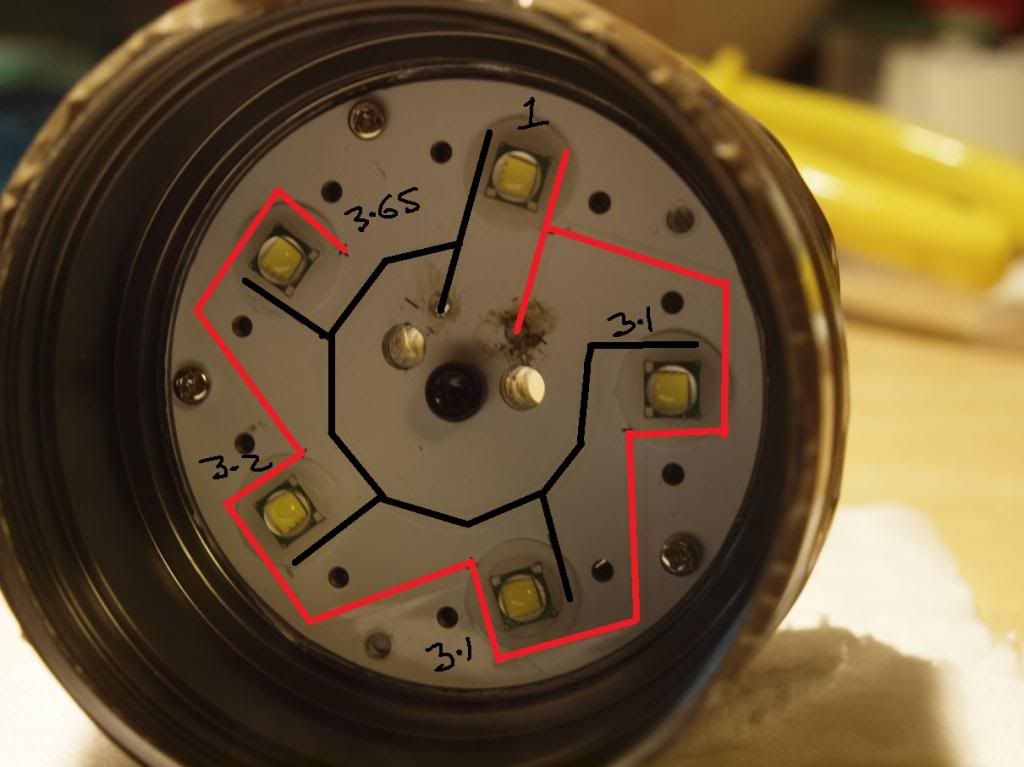

It’s clear that the top led is putting out considerably more light than all the others and while the rest show some subtle tint differences their brightness seems to be more in line with each other. At first I put this down to emitter bin variations or something like that but once you look at the pcb that the LEDs are mounted on and study the traces that connect everything up it becomes clear that things are not shared very equally. Or rather four are on a mostly equal footing and the last one is enjoying some prime real estate! ![]()

I had a quick go at measuring the total circuit/trace lengths for each LED to see what the relationships really are.

Here’s what I came up with (trace lengths are relative units)

So you can see that the + and - traces actually run counter to each other ensuring that 4 of the emitters share pretty much the same total trace distance. It’s not perfect as the + trace path is marginally longer than the - running on the inside but they are pretty evenly balanced. Unfortunately this configuration leaves one emitter at the top that gets a trace distance that is just one third as long as all the rest. Lucky bugger!

Well we all knew parallel wiring LEDs is not ideal at the best of times, what with forward voltage differences and all that but what does this rather big difference actually mean for the total output of my torch. I know one emitter is getting a higher voltage and therefore an unfair share of the current, outputting more light as a result but also running slightly less efficient/hotter than all the others. But will evening things out actually improve output by a noticeable amount? The total current draw and therefore power output should stay mostly the same it’s only going to be divided among the leds slightly differently based on more evenly matched led voltages. Right?

In any case I’m tempted to go back in there, remove some dielectric on the traces and solder on some shortcut wires. Evening up the trace lengths just to cut out as much of those resistance losses as possible. Certainly can’t be bad for overall efficiency and if it boosts output even a bit then all the better.

But is it worth the hassle…it’s fairly cramped in there and I could always mess up an led dome or two fiddling about…I dunno…convince me one way or the other ![]()

Cheers

PS. Or maybe I should just dedome that top emitter to increase throw a bit, I hear dedoming can increase forward voltage by a bit as well so maybe that would be the ideal solution ![]()

Not sure about the extra green/yellow I’d be introducing though, I really like the tint as it is…

So I noticed something today that convinced me that I need to even up those trace lengths. For the health of the torch/leds as much as the gains in efficiency/output.

Running on the Kinoko IMR cells and looking at the individual led outputs (using a black card cutout to let only one emitter light through at a time.) I was pretty alarmed to see the top emitter go from normal output/tint towards a much cooler shade and ending up almost at the stage of overdriven XM-L “Angry blue”. It’s hard to describe exactly what this looks like but I’m sure any of you who have experimented with overdriving XM-Ls know it!

It’s the unmistakable sign that you’ve pushed things too far and need to take it back down a notch or two ![]()

This happens only on high and happens pretty fast, so it changes within the first 15s or after turn-on, the rest of the LEDs are fine and stay much more stable.

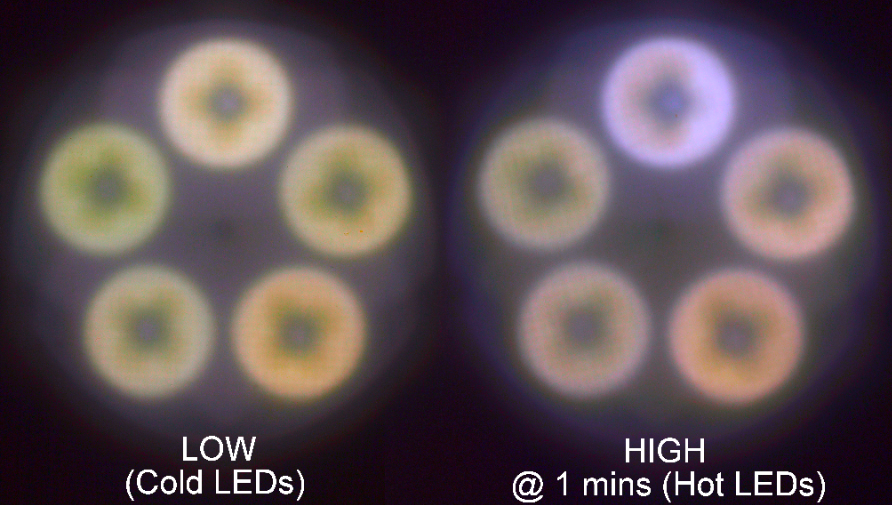

I took some more photos to confirm what I was seeing.

No these aren’t skittles…they’re XM-L NW emitters ![]()

Here on the left I show a shot of the emitters running on low straight after turn-on. This gives a baseline of what the LEDs are doing when cold and driven with a small current.

On the right what they look like on high with ~16.5A shared between the emitters and taken after they’ve had a chance to warm up a bit.

Then I adjusted any exposure differences, white balanced to remove the overall greenish cast and boosted the saturation to exaggerate the differences in tint.

So I think it’s pretty plain to see what’s going on there. That top LED is turning very blue compared to the rest. This means it must be being driven considerably harder than the 3.2-3.4A I was expecting to give each emitter. In fact I have never seen a NW XM-L turn that blue even when driven with up to 4.5A on aluminium PCBs. I have a T6-3B in a C8 with a 12x7135 pulling a solid 4.5A that looks absolutely fine even when left on for quite a while.

So how much current is that XM-L actually seeing? Well my guess is well over 5amps and considering the aluminium PCB it’s mounted on that’s clearly not safe territory to be in if those images are any guide.

So I guess I’m opening her up again to sort out those traces, anything else I should do while I’m in there? ![]()

Cheers

it’s @ cpf

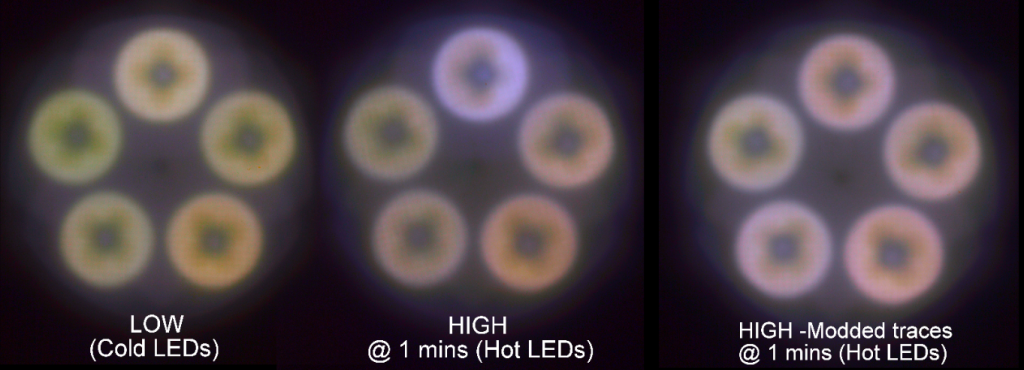

Ok, traces modified and with very good results. Glad I put the effort in here, it really shows!

The new pcb wiring after sanding off little bits of the dielectric coating and soldering 18awg wires to the little copper patches.

Needed to turn my soldering station to it’s max 450°C setting to have any chance of soldering to the heatsink pcb. I didn’t remove the pcb because I didn’t want to have to reapply all the thermal grease. This made it a bit of a task but I guess that’s a good sign, means the heatsink is doing it’s job well.

Here is that same emitter image from before but with the addition of the results after evening up the traces with 18awg wires.

(Shot with exactly the same exposure and processed with the same colour correction so the difference you see is representative of the real thing)

The top led is no longer angry blue and seems to be nicely in line with all the others, doesn’t seem to have harmed it’s output much having been overdriven for a fair amount of time either.

Much more even output from all the LEDs. No.4 and 5 are no longer the dimmest and it actually looks like no.4 is now the lumen king. This one always seemed to be the coolest of all, tint wise, so perhaps it makes sense for it to have the brightest output as well.

These results are reflected in real use as well, the light is noticeable more potent than before, with a lot less blue in the overall beam and what feels like more stable output as well. I always saw a faint dimming in the overall beam soon after turning on, concurring with the top LED turning blue and heating up. This is no longer an issue.

It’s a shame I don’t have a lux meter or some way of measuring the total output because I am certain there would have been a clear reflection of all these improvements in those readings ![]()

Anyway I’m now even more pleased with the light and with that I would say it’s DONE!* :bigsmile:

Linus

*Except of course for the beam shots. Coming soon.

Linus, you are an inspiration to us all. Your attention to detail is amazing.

Thanks man, glad it’s of use to someone. ![]()

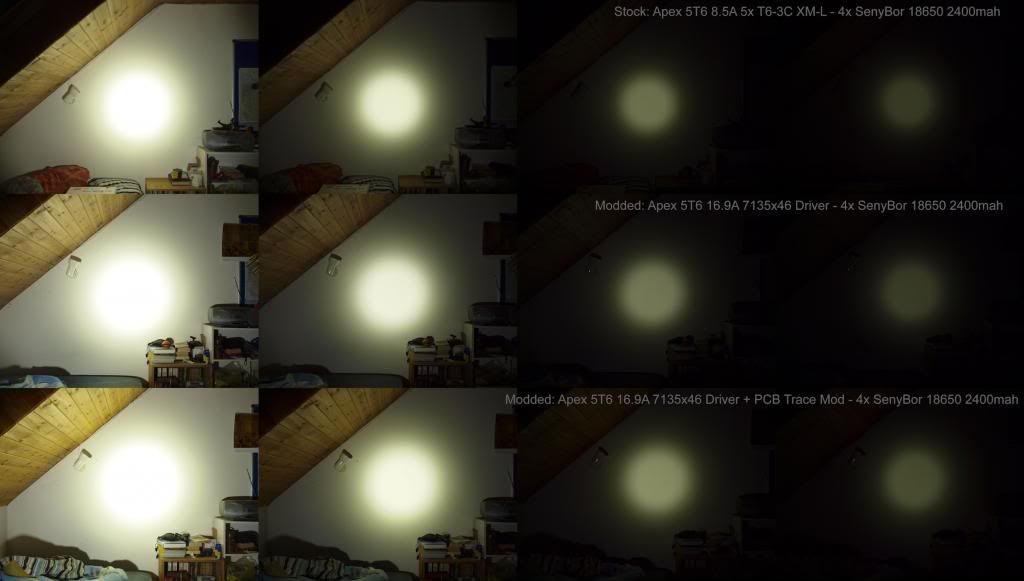

Alright I finally have some indoor beamshot comparisons to show. Was hoping to also include the Kinoko IMR test results here but I had a bit too much fun with the light outside earlier and they’re still recharging. ![]()

So this shows a comparison between the stock Apex, taken a year ago on the same set of batteries (albeit brand new at the time),

the first iteration of the Mod without the mcpcb trace modifications and finally the current “final” version of the light.

You’ll see why I wasn’t too keen on showing the initial comparisons between Stock and first iteration mod, the combination of older batteries, slightly different distance from flashlight to wall and generally saggy performance of those batteries doesn’t show a particularly true representation of the increase in performance.

I may also have had a particularly eager driver in my stock apex, perhaps pushing more than the advertised 8.5A. Unfortunately I never did get round to doing a proper tailcap measurement on it so I’ll never know.

But then we look at the shots after the trace mod, now that’s what I’m talking about! Still the same batteries but look at the further increase in output over the modded first iteration!. And all I did was even up the trace lengths and eliminate the resulting overdrive on the top LED.

Also notice how much nicer/warmer the tint is as a result, this is particularly obvious on the wooden ceiling boards lit up by the spill and bounce from the wall. That’s not a difference in camera white-balance or anything in the scene, it’s a difference I notice in regular use as well. Lovely improvement on what was already my favourite light in terms of tint! ![]()

And all I did was solder some extra bits of 18awg wire into the head! Great returns for that mod for sure.

-

As a rough comparison and just to give a sense of perspective to the above results.

Here is what this test setup looks like hit by a T-Mart HD2010 with an XML U2-1C on Led-tech Copper pcb using the stock DD driver and a single Trustfire 26650. Everything else is the same.

It pulls a healthy 5A on a fresh battery and is a great thrower but next to my Apex it looks a bit pants! The apex throws almost as well and illuminates the whole forest in front of you rather than just a single tree! Love it 8)

I’ll post up the Kinoko IMR results when I get round to doing the test again with them but wouldn’t expect a very noticeable difference to the above. These tests are done about 5-10 seconds into turn-on with freshly charged batteries and in that scenario even the saggy Senybors come close to matching the IMRs in terms of total initial output. The IMRs just peg the performance at 16+ amps and hold it there for at least the next 5mins while the Senybors drop steadily and much sooner.

In any case this light now chucks out more lumens than I can sensibly use in most situations! ![]()

Cheers

You have done well to fix the problem. I take my hat of to you.

Very nice.