I’ve said it before and I’ll say it again. Practice does NOT make Perfect. Practice only makes permanent.

Only perfect practice makes perfect.

Whether or not you give up is up to you, but I would suggest a method that might save you some money:

Go to the dump, the trash, anywhere you can find some modern electronic toys that are “dead”. Take them apart & scrounge the littlest parts you can lay your hands on inside. Look at the driver you want to Mod and figure out what parts from the toys approximate the sizes of the good stuff.

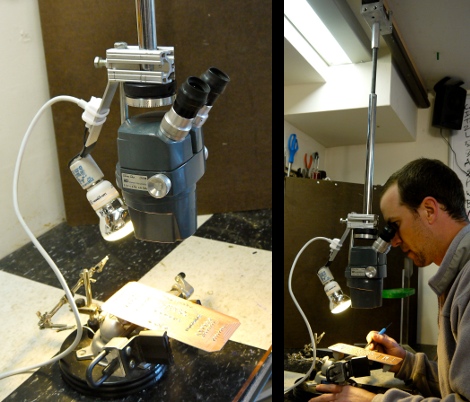

Now get “artsy” and solder the trash parts together, or to pads on the trash circuit boards. Keep analyzing your methods and work out a way to do it with the smallest, cleanest, best solder blob possible. Use a dead toy as an example — it didn’t fail for bad solder joints! Get some serious magnification and examine your joints in the most minute detail you can muster, and compare each one critically to the ones the toys had from the factory.

This will be a good time to acquire or build tools to hold the wee parts in whatever places you want them to stay.

As often as not, you can pick up a wee droplet of solder & use that both to transfer the heat to the joint and to transfer itself as soon as the joint is hot enough for it to flow. That makes more sense in my head than it probably does to read, but you’ll see it. Carrying the solder droplet in on the tip leaves your other hand free to hold parts.

Once you can solder trash parts together in a way that looks like how it was made to start with, hold on to that method and repeat it until you can do it Every Single Time. THEN PRACTICE THAT.

You won’t be working on repairing electronics, you’ll be working on improving your soldering technique, that’s all.

Once you feel comfortable with trash, try removing what you did to your paid-for drivers, clean them up and try again with one. It may be fried already, but it won’t cost you any extra. Continue to examine your work, analyze and criticize. And strive for improvement. If you get one of your paid ones working again, share that with the family!

You can quit if you want to, but that’s what I’d do. Okay, what I DID… Yes, I’ve been soldering since Integrated Circuit referred to a race with a mix of dark- and light-skinned people in it, but when I did decide to go SMD, I found practice materials abounded in the trash.

Just a simple suggestion. Just trying to help. Hope it does.

But I’m just…

Dim

![]()