Well, I have been thinking a lot on this limited edition light and I have a couple things to go over with you.

First off, I have a logo here and I have a sample light coming, which I will post photos of, when it arrives.

This would be laser cut in the knurled section of the body. Of course, the light is black, so the logo will be silverish looking, not black. As far as how many lights (the 25 does not mean I will only do 25), it will just depend on the number of members who pre-pay for the lights. DO NOT try to pre-pay now please! This is just an information or status thread, if you will.

Also, I have crunched the numbers and I have a breakdown of them:

- Host - $20

- Heat Sink - $4

- Driver - $5

- Lens - $1

- LED XM-L T6 3C - $5

- Shop costs - $10 (that's solder, wire, Arctic Alumina, shipping fees to get stuff in here, etc.)

Total for an XM-L T6 3C would be $45

Shipping costs (including packaging materials)

- CONUS Priority Insured - $13.00

- International (Priority small flat rate box) - $27.00 Or with Registered $40.00

- International First Class - $16.00 Or with Registered $29.00

- Note: The only way to have the package insured against loss or damage is with Registered mail. If it goes without adding registered, the loss or damage cannot be claimed, nor will it be paid for by USPS or me.

This is pretty much at cost here. I am not trying to make profit here, just trying to keep from making a loss out of it.

Unfortunately, the overall cost, with shipping, is more than a budget light should be and probably more than it is worth, especially for International members, but I don't see any other way. I was excited to possibly do this, but not excited by the price. I just cannot do it any cheaper without taking a loss on it. With a small run like this, there's not a lot of cutting costs by volume, as the big boys do, so this is what it is.

Lead times:

Due to the Chinese Holidays, I will not order until the last week of February. Even with that, I feel I will not see components until the end of March. Therefore, I must set a 60 day lead time, begining the first of March, for "shipment" of the lights. That means the First of May, the lights would ship out. If things were to arrive sooner, then the schedule would move up. It's something I cannot control from this end, as I can only wait for the components to come in.

Once I get the sample light, I will post photos and I will start a "Pre-Order" thread. Then we will see if I get enough orders to warrant doing this run. If I get 25 or more, I will do it. Less than that, I just don't think it is worth it. The maximum I will do is 40 pieces. I don't think I can handle any more within the time frame that I have allotted myself.

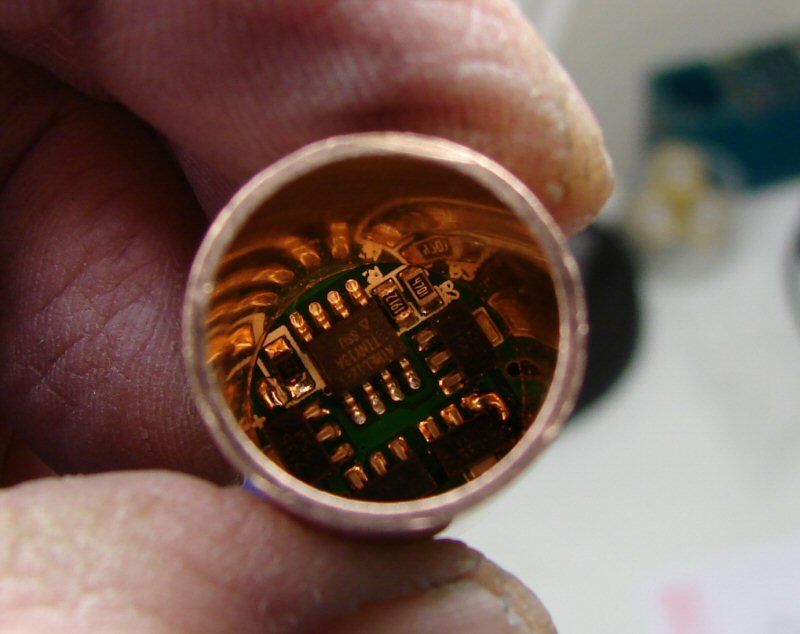

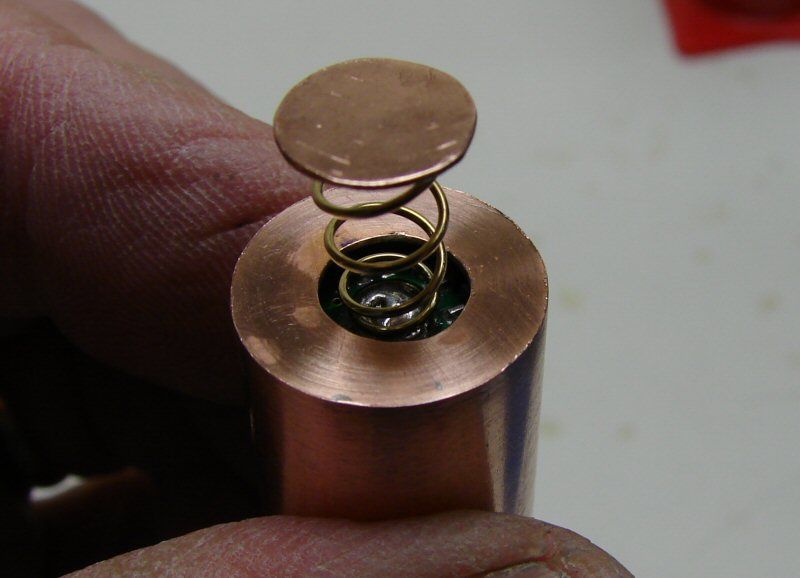

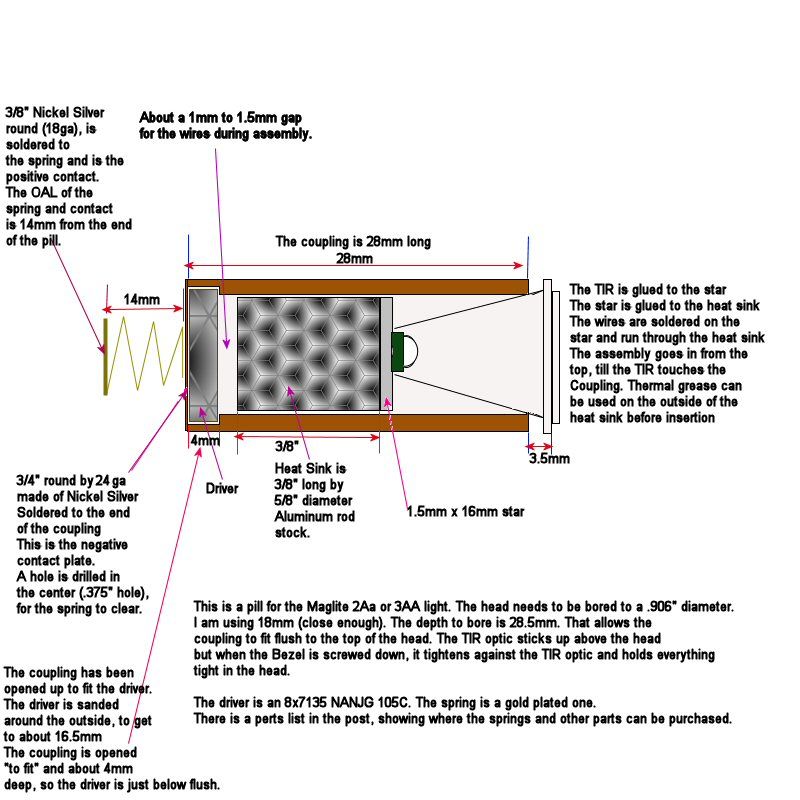

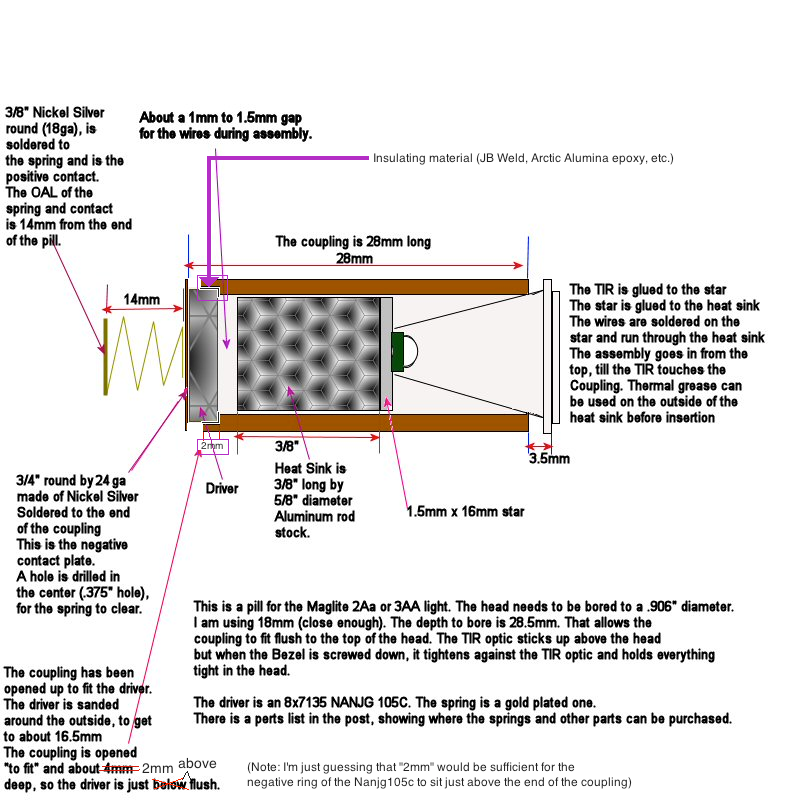

I am working on modifications to the pill/driver assembly, to make it more dependable and more rugged. After doing 3 or 4 of the driven lights, I can see weaknesses that need to be addressed. The updated pill/driver combo will go in all of these limited edition lights. I will have a sample of how they are done, once the sample light comes in. I will build it and show the photos of the guts. That's all for the moment. I will update when I have something to show.

EDIT: These lights do come with a dummy cell, for 14500 use and I am "guestimating" the lumens to be 350 lumens on high, 125 lumens on medium and 30 lumens on low. That is just a rough guess, but I think it will hold true and it gives something to think about for buyers. It is not a super bright light and max range (Not Maglite's bloated range), is about 40-50 yards.

02-17-13 UPDATED: Look at Post#8 for the NEw Pill Design. Never Mind, it's a FAIL.

02-18-2013 New Update: This will be a Nichia 219 High CRI light! The recent poll showed the Nichia winning at three to one odds and Craig just lowered the price, so it's a done deal. It will be the Nichia with a 1.4 amp or 1.5 amp driver.

We only live once or twice

We only live once or twice  ...might as well have what we want!

...might as well have what we want!